Asaclean™ saves money steadily

Some customers new to Asaclean™ as a means of cleaning their moulding machines might think that an expensive purging compound may be outside their budget. However, many customers worldwide have realized significant cost savings and efficiency improvements with Asaclean™.

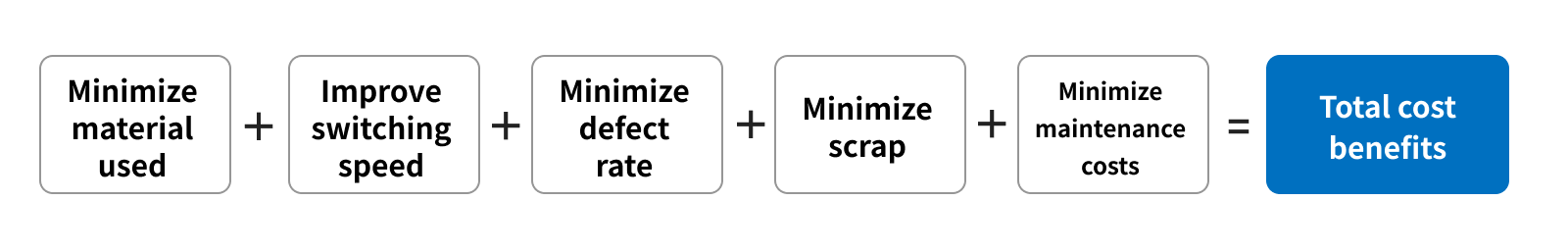

Asaclean™ improves the overall cost structure

Due to its high cleaning power, Asaclean™ provides an overall cost advantage over other means to the cost structure involved in the maintenance of moulding machines.

-

Minimize material usedDue to Asaclean™'s high cleaning power, material loss during colour and material changes is reduced from 30% to 90% compared to switching with the next run. This reduction leads to a decrease in material costs.

-

Improve switching speedAsaclean™ provides high cleaning power by selecting the appropriate grade. Compared to other means, colour and material changeover can be performed in a shorter time, thus saving time.

-

Minimize defect rateWe can effectively and efficiently keep your machines clean with Asaclean™'s high cleaning power and low residue. This efficiency reduces the frequency of defects caused by residue.

-

Minimize scrapThe amount of Asaclean™ required to complete the moulding machine cleaning is much less than with material resins that require repeated purging. This reduction reduces scrap.

-

Minimize maintenance costsUsing Asaclean™ keeps the moulding machine in good condition and reduces the frequency of teardown. This effectiveness reduces maintenance time, increases uptime, and reduces maintenance costs.

Higher productivity with Asaclean™ than with material or virgin resin

Asaclean™ is a purging compound explicitly developed for injection moulding machines, extruders, and blow moulding machines. Asaclean™ offers superior effectiveness over the conventional purging process. You may potentially waste time and materials with traditional methods such as cleaning with virgin or regrind materials and do not permanently wholly remove previous run or contamination. This incomplete cleaning leads to deteriorated conditions inside the moulding machine and reduced production efficiency. As a result, you may incur a significant cost with having to teardown or lose opportunities.

Compared to conventional processes, Asaclean™ improves cleaning efficiency, reduces material costs, and maintains cleanliness inside the machine. The cost of purging compounds is only a tiny portion of the total cost, and you can realise significant cost advantages when looking over the total cost.

With Asaclean™, you will find the best grade

Asaclean™ offers various grades to meet your needs with multiple resins and processes. The Asaclean™ team will provide full support from grade selection to introduction to achieve steady cost reductions. Please feel free to contact us.