Asaclean™ contributes to reducing CO2 emissions

Today, corporate activities and the achievement of sustainability goals are closely linked. Asaclean™ provides concrete solutions in the form of reduced CO2 emissions for you, helping you realize your environmental commitment. How can Asaclean™'s powerful cleaning effects help you reduce your CO2 emission?

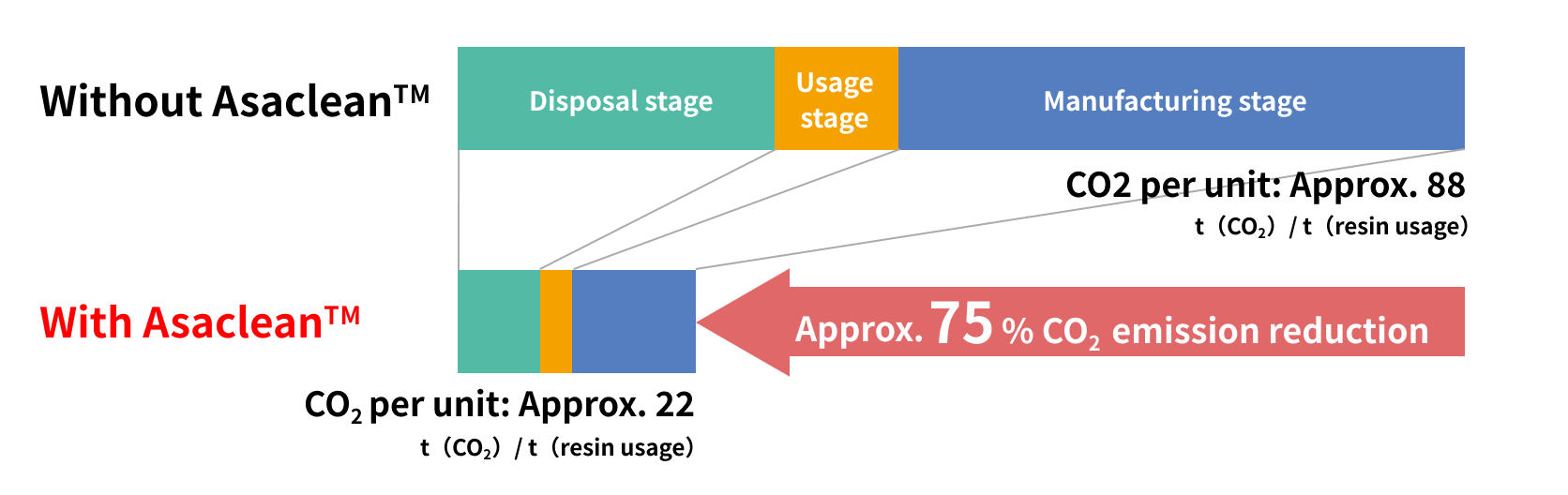

Minimize the resin used in cleaning

You can reduce the total amount of resin, and Asaclean™ required for material changeover compared to with and without Asaclean™. You can reduce the total amount of resin used, resulting in lower CO2 emissions during the production of resin and Asaclean™.

Minimize energy consumption in material changeover

Material changeover naturally consumes electricity to run the machine. With Asaclean™, you can complete cleaning in a shorter time. This shortened changeover time reduces CO2 emissions derived from electricity consumption.

Minimize scrap

You must dispose of the resin used for the material changeover. The amount of waste (resin and Asaclean™ used) significantly reduced with Asaclean™ compared to without Asaclean™. This reduction in the total amount of resin used minimises the CO2 emissions generated by the incineration disposal.

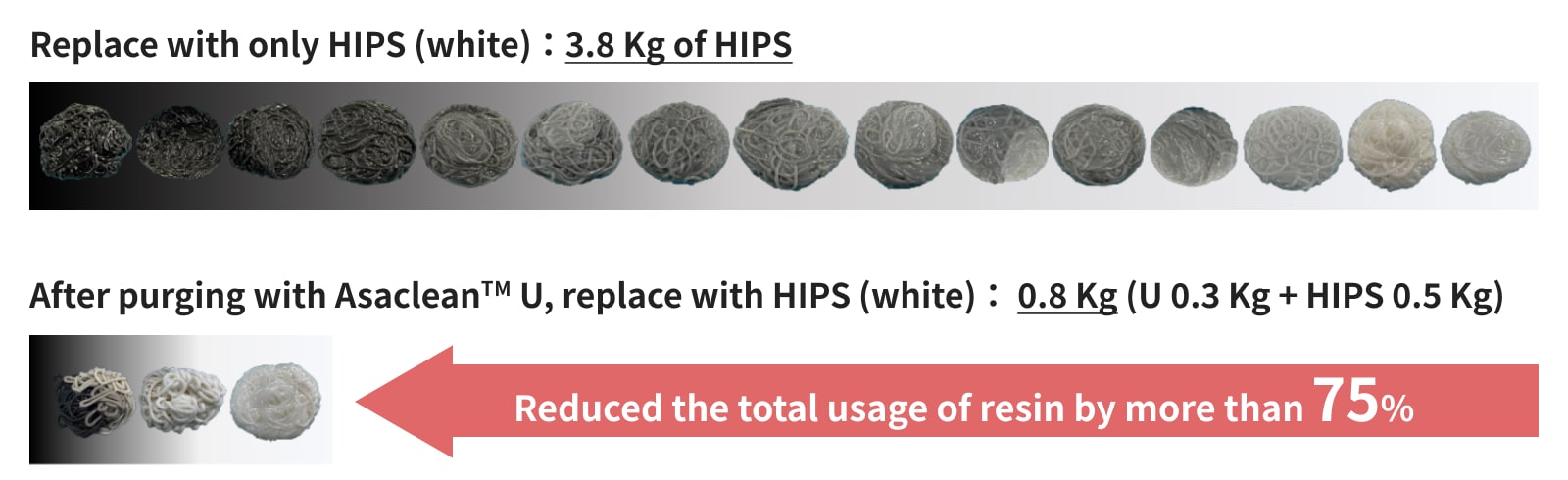

Case : material changeover from ABS(black) to HIPS(white)

In the material changeover from black ABS to white HIPS, the amount of resin used is 3.8 kg when replacing without Asaclean™, whereas the amount used drops to 0.8 kg with Asaclean™ U Grade. This change represents a more than 75% reduction in resin use.

With Asaclean™, a dedicated purging compound, achieving highly efficient cleaning that you can never attain by replacing the resin used is possible.