Q&A

Q&A for oil film detector, LMD-3000, Apolarm™M (FAQ)

- Examples of Past Usage

-

Q

What fields has the device been utilized?

A

Actual industries where the device has been utilized:

Scientific plants, cement manufacturing (mining stations) plants, the paper industry, electric power companies(thermal, hydraulic and nuclear energy) water purification (sewage) facilities, food processing factories, auto manufacturers, semi-conductor manufacturers and pharmaceutical manufacturers. - Measurement principles and other information related to the oil film detector, Apolarm™M

-

Q

What kind of principle is used for Apolarm™M to detect oil film?

A

By utilizing the property that the refractive index of oil is larger than that of water, laser light is applied to the water surface, and the amount of reflected light is measured to detect the oil film.

Q

How much is the thickness of detectable oil film?

A

Oil film thickness varies with the oil type and viscosity. Lubricant oil film is detected when it is about 0.2 μm or thicker. Films with oil properties can be detected if any formed. It can detect not only oil film, but also oily layer.

Q

What is the danger level associated with the laser in the oil film detector, Apolarm™M?

A

The detection device uses a class 2 (less than 1mW of visible light) laser beam. Be sure not to look directly at the laser beam or use a lens to concentrate the light. If you look directly at the laser beam for long periods, it could lead to loss of vision.

- Before Purchasing

-

Q

Can you explain details about Apolarm™M and demonstrate oil film detection at our factory or office?

A

Yes. Please contact our Sales Division or agency. Our representative personnel will visit you with the equipment. Please note that the personnel cannot visit you.

- About Installation of Apolarm™M

-

Q

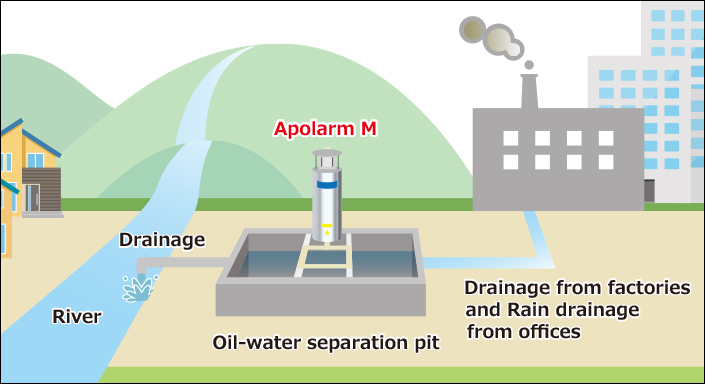

What kind of location is desirable for installing Apolarm™M?

A

We recommend you to install the drainage pit, oil-water separation pit and drainage ditch.

Q

Can the device still detect properly if placed near the running water?

A

Yes, it can. However, please place the device in an area where the speed of running water overlooked is 1-2m/s or less and the waves are as small in height as possible.

Q

Our drainage pit has an inflow of wastewater which produces tall waves and foam. Will the device work there?

A

Bubbling at the surface of the water may defuse reflection of the laser beam, leading to errors as a result. Please place the unit in an area where bubbling at the surface occurs as little as possible. It will also be necessary to install a device (such as a baffle plate) which fits the environment and suppresses the fermentation.

Q

Can the device be placed outdoors?

A

Yes, it can. The device is completely clearance sealed (meeting IP66 standards) and can be placed outdoors.

Q

Can the device detect properly if there is vapor on the surface of the water?

A

In an atmosphere where steam or vapor arises from the surface of the water, it is possible that system errors may occur. We recommend obtaining other optional equipment (sold separately) such as a steam resistant hood, AMH-1100.

Q

How far can the signal cable be extended?

A

Please ensure that the wiring of the signal cable results in line resistance of 550Ω or less in both directions, including external connection load (the general criterion for length is approximately 300m or less). In addition, the signal cable also handles faint pulses (numbering only a few mA) and to prevent noise, please ensure that the contact signal and current output cables are separated from other power sources.

Q

What cables are recommended when extending the signal cable?

A

Please make your own arrangements for an extension cable. Our recommendations for extension cables are as follows (CVVS 1.25SQx8C or CVVS 2.00SQx8c).

- About Use of Apolarm™M

-

Q

What is the extent of the laser irradiation (scanning) on the water surface?

A

The extent will be changed by the distance from the bottom of device to the water surface. The scanning diameter will change by the distance between oil film detector and water surface. The size of scanning diameter of laser is followings,

1.0m ・・・ about 15 cm in dia.

2.0m ・・・ about 20 cm in dia.

3.0m ・・・ about 35 cm in dia.

4.0m ・・・ about 50 cm in dia.Q

If there is garbage (floating matter) on the surface of the water, will it be a false alarm?

A

Floating objects are available on the water, it occurs the system errors for the detector as following cases?

1. Objects that reflect light well (aluminum foil, plastic, iron bacteria, etc.) stay for a long time

*The detected level will be HIGH LEVEL (upper limit error).

2. Objects that do not reflect light (fallen leaves, birds, etc.) stay for a long time

*The detected level will be LOW LEVEL (lower limit error)

3. When the water runs out

*It also detected level will be LOW LEVEL (lower limit error)Q

Can oil film be detected on a frozen water surface?

A

Oil film detection is disabled when the water surface is frozen. However, if oil films are flowing on ice can be detected.

Q

If it will install the detector outdoors, will it be affected by direct sunlight?

A

If direct sunlight strikes the device and the temperature of the internal parts rises, it will increase the speed of the device’s deterioration. As such, we recommend installation of the optional (separately purchased) standard light-shielding hoods, AMH-3000 or AMH-3010.

- About Maintenance and Repairing of Apolarm™M

-

Q

How long is the warranty period?

A

It is based on one year from the installation on the site where oil detector is actually carried out the monitoring of oil leak, or up to 18 months after importing. As it may vary from region to region, please contact the local dealer for details.

Q

Do you have any consumable parts (maintenance parts)?

A

Yes.

1. Laser module

We recommend replacing every 4 years from the beginning of use.

2. Motor

* We recommend replacing every 7 years from the beginning of useQ

Is it possible to maintain the oil film detector, LMD-3000 on site?

A

It is possible to do. Only maintenance qualification certified persons can do the work. We will submit a "work report" after work.

Q

Can repair the failed oil film detector on site?

A

Depending on the repair content, please contact your local distributor.

Skip to the contact formQ

Please explain what kind of daily maintenance is necessary.

A

In general, no daily maintenance is necessary.

You don’t usually have to do for daily maintenance work.

However, if the glass portion of the apparatus for emitting and receiving the laser beam is dirtied, it may become easier for output errors to occur (the potential will change depending on the amount of dirt). Please clean it with a glass cleaner and cleaning cloth, as necessary (If a glass cleaner is used, please wipe down the surrounding area so that no trace of the cleaner remains)

In addition, to confirm whether light is being received at the correct level, it is recommended that once or twice a year, the round tray attachment (testing plate) be used and confirm the level of light received for water and oil.Q

Please tell me how to respond to solve it if an error alarm occurs.

A

After confirming the contents below, please contact with your local distributor.

1. Open the lid of the touch panel and touch the “LOG” button to see “LOG DATA”. Please confirm the status (ex. NORM, ALRM, HIGH, etc.) displayed to the right of the date.

2. Place a white paper (ex. copy paper) directly beneath the sensor and confirm the status of laser beam reception.

Warning!

The laser will be difficult to see beneath sunlight, so please exercise caution.

When confirming the level of laser light, please do not look into the light emission and reception apparatus.Q

Is each setting value adjustable?

A

Yes.

To adjust settings, it is necessary to open the lid of the touch panel monitor. When closing the lid of the touch panel monitor, please make sure it closes securely, as water may enter the interior of the device, leading to corruption, if the waterproofing O-ring becomes caught in the lid. - About an optional accessories

-

Q

What is available of the optional accessories?

A

1. Sun shade hood: AMH-3000 and AMH-3010

2. Antifogging hood: AMH-1100

3. Installation stand: AMC - 1000 (SS) and AMC - 1010 (SUS 304)

4. Additional relay for oil film warning alert and Isolation function: AMZ - 3100 - 05

CAUTION:It will unable to retrofit after purchasing, and please ask it when you order if you need it.

5. External monitor display unit: AMM - 3000

Questions about the oil leak detector, Apolarm™C

- Examples of Past Usage

-

Q

What fields has the device been utilized?

A

Chemical plant, cement manufacturing (mining plant) factory,paper industry, electric power companies (thermal, hydraulic and nuclear energy), food processing factories, auto manufacturers.

- Basic configuration of the oil leak detector, Aplarm™C

-

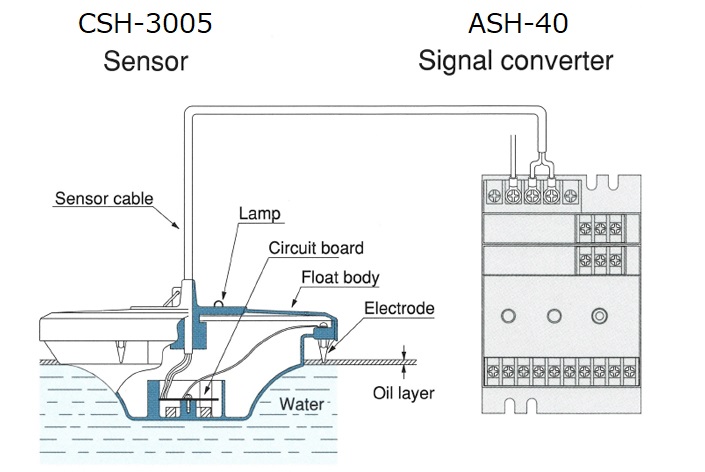

Q

What is the basic configuration of CSR-3005 system?

A

Oil leak detector, CSR-3005 and signal converter, AS-40 must work together.

- Measurement principle and related items of oil leak detector, Aplarm™C

-

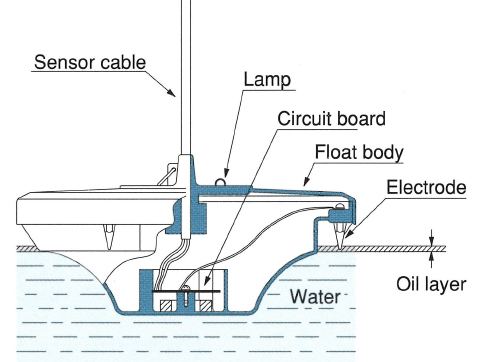

Q

What kind of principle does the oil leak detector, Aplarm™C detects oil?

A

Fully sealed detector is equipped with three electrodes. Normally, when the electrode is in direct contact with water and oil flows into the water surface, the electrode contacts the water through the oil, so the electrostatic capacity greatly changes, this change is detected and the contact of the leakage detection alarm is output.

Q

How thick is the detectable oil?

A

It is possible to detect oil layer thichness from to 3 - 5 mm.

Q

Please tell us under what conditions detection is possible.

A

1. The specific gravity is smaller than that of the water.

2. The oil is not water soluble (ether, methanol, and similar oils are not detectable.)

3. The dielectric constant is five or lower

Dielectric constants of 5-10 are detectable, but the detected layers will be thicker in size. - About Installation of Aplarm™C

-

Q

What kind of location is desirable for installing Aplarm™C?

A

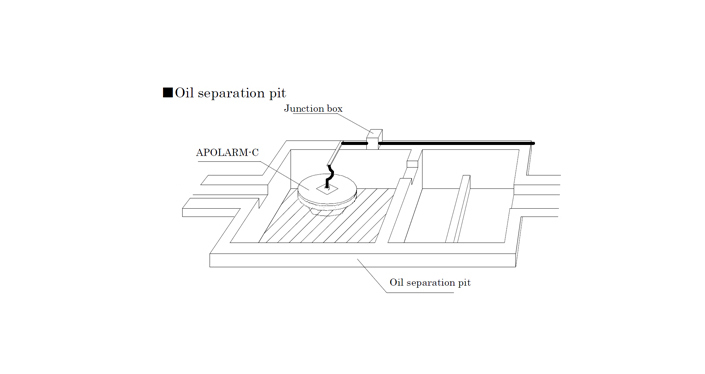

We recommend you to install the drainage pit and oil-water separation pit.

Q

Can the device still detect properly if placed near the running water?

A

No, it can't.Please install the device at the drainage pit where does not have water flow.

Q

Can the devicce be placed outdoors?

A

Yes, it can.The device is completely clearance sealed(meeting IP67 standards)and can be placed outdoors.

Q

How far can the signal cable be extended?

A

Please consult the following specifications when extending the cable.

Usage conditions Reference cable length 600V CVV 2mm22c Acceptable inductance and capacitance of the cables which connect the detector and converter

Acceptable inductance: 2.0mH and below

Acceptable capacitance: 0.3μF and belowFor safe use: 2 km or less **Reference figures for acceptable cable inductance and capacitance**

When connecting 600V CVV 2mm2 2C cable to conduit tube.

Acceptable inductance…0.6-1.0mH/km

Acceptable capacitance…0.1-0.15μF/km

*The listed figures for acceptable inductance and capacitance are for reference only. For further details, contact the cable maker.Q

What cables are recommended when extending the signal cable.

A

Please use a CVV 2mm22C cable as example.

- Question regarding usage of the oil leakage detection unit, CSH-3005, Apolarm™C.

-

Q

Please tell us how to use the optional accessories.

A

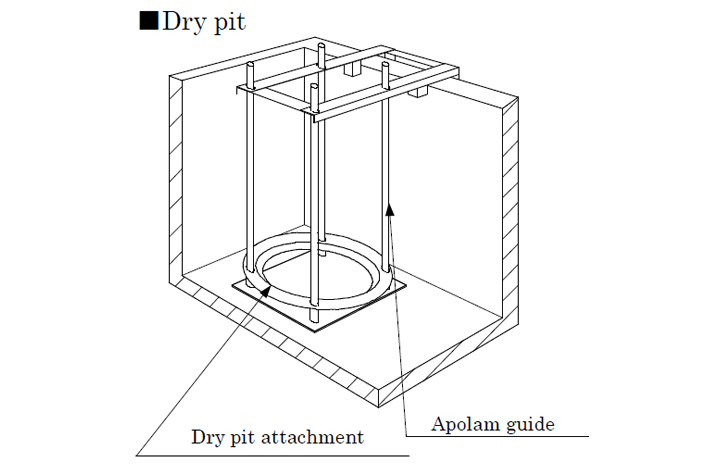

If drainage ceases, please assemble and use the low water guard (TC-SE) and guide bar.

A

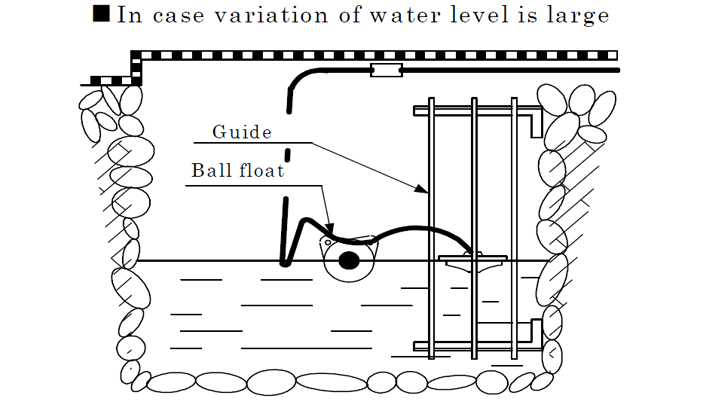

If the change in water is dramatic, please use the ball float (4A-8) with the low water guard (TC-SE) and guide bar.

- Regarding maintenance and repair of the oil leakage detector, CSH-3005, Apolarm™C.

-

Q

How long is the warranty period?

A

It is based on one year from the installation on the site where oil detector is actually carried out the monitoring of oil leak, or up to 18 months after importing. As it may vary from region to region, please contact it the local dealer for details.

Q

Are any of the parts expendable (can they be replaced or repaired)?

A

No. Due to the sealing structure of the device, it is not possible to repair. In the event that the device does fault, it will be necessary to exchange it with a new one.

Q

Please explain what kind of daily maintenance is necessary.

A

1. After installing the sensor, turn on the power to the converter and measure the P-N current of the sensor.

The normal values are as follows.

No oil present: approximately 14mA DC

Oil present: approximately 4mA DC

Please gauge the following elements on first use and once a year.

2. Elements to check day to day (once every one-two weeks)

(1) Is the float (Apolarm™C) upside down or tilted to an extreme degree?

(2) Is there a large amount of garbage in the pit or algae growing?

(3) Has the Apolarm™C moved outside the guide?

(4) Are there any other obstacles that may be interfering with detection?

Please be sure to inspect the device closely after frozen weather, high temperatures, strong winds, waves etc., torrential rain, typhoons and similar events.Q

How do you determine if a fault has occurred?

A

Normal converter operations are as follows.

Current value LED Remarks OIL ALARM SYSTEM ALARM OmA DC(Disconnection) Lighting(green) Lighting(red) Disconnection alarm 4mA DC Unlighting Unlighting Oil leak alarm 14mA DC Lighting(green) Unlighting normal 21mA DC Lighting(green) Lighting(red) Short circuit alarm 1. Inspection procedures for the Apolarm™C

A fault can be confirmed by checking the (OILALARM) action indicator light on the surface of the Apolarm™ float. After confirming that the converter is functioning properly, connect the Apolarm™C and place the Apolarm™C on the surface of the water.

At those times, the green operation light will blink. Next, raise the Apolarm™C in mid-air and the operation light will disappear. If the device does not function in this manner, the Apolarm™C may be broken.

2. Blown fuse

The converter carries a fuse within the safety barrier, but to preserve the intrinsically safe construction of the device, the fuse cannot be changed by the customer.

3. Other abnormalities

4. Detection sensitivity is poor

If thicker oil layers are being detected during the actual liquid test, please clean the electrode portion of the Apolarm™C.

If after taking these steps, the Apolarm™C still does not operate correctly, there is the possibility of an abnormality.

5. Beyond normal activation of the oil leakage detection alarm (OIL ALARM), be aware that a false oil warning may also occur in one of the following situations.

(1) The Apolarm™C is raised in mid-air.

(2) The other high frequency signals emitted from the electrodes of the Apolarm™C are insulated.

EX1) Insulation occurs after dirt has dried on the attachment.

EX2) An error occurs during equipotential grounding.

EX3) The Apolarm™C is raised from the surface of the water by strong winds.

6. The system abnormality warning (SYSTEM ALARM) will activate in the following circumstances.

(1) The Apolarm™C converter cabling is severed

(2) Insulation failure or short circuit within the converter cabling

(3) The convertor’s fuse is blown

(4) The converter is powered OFF •••••• in those cases, the LED light will disappear

In the event of a false alarm or malfunction, please check the above and confirm the cause.

- Options and other elements

-

Q

Please tell us about optional parts (sold separately).

A

1. Converter storage box, ASB-30.

2. Ball float, 4A-8.

3. Junction box.

4. Guide bar.

5. Guide bar support/made from SUS304.

6. Guide bar suport/made from SPC steel.