|

|

|

|

Major Features

- Bond strength with explosion bonding is greater than with any other bonding process,

such as roll cladding, overlay cladding, etc.

- Almost all the existing metals can be explosion bonded, including tantalum and zirconium

which can not be bonded with other metals by any other process. Explosion bonding also

enables the cladding of titanium with aluminum, which is not possible by overlaying.

- Forged steel can be explosion bonded.

- Multi-layer clad composites are also possible with explosion bonding.

- To assure the quality of the bond, all BACLADTM products are inspected by ultrasonic

testing.

- Explosion bonding is a cold process which is free from the influence of heat, so inherent

properties of the materials are not degraded.

- There is no limit to the thickness of the base metal to be explosion bonded, provided

that the total weight of both metals is less than 30 metric tons.

- Standard delivery time is 30 to 40 days after receiving raw materials.

- We are committed to work with customers to meet every need, with flexibility regarding

lot size and product dimensions. To support customers' R&D activities, we welcome

requests to work with sample products.

Ultrasonic Test

|

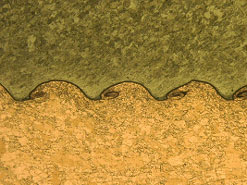

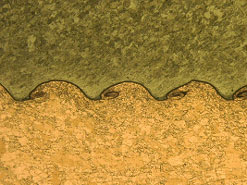

Interface of cladding and base metal

|

|

|

|