Chemical and heat resistance

Chemical resistance of MEF™

Thanks to its excellent chemical resistance, MEF™ can be used for a wide variety of applications.

| Chemical | Rating |

|---|---|

| Hydrochloric acid (10%) | ◎ |

| Hydrochloric acid (36%) | ◎ |

| Sulfuric acid (10%) | ◎ |

| Sulfuric acid (30%) | ◎ |

| Nitric acid (10%) | ◎ |

| Nitric acid (40%) | ◎ |

| Phosphoric acid | ◯ |

| Boric acid | ◎ |

| Potassium hydroxide (10%) | ◎ |

| Sodium hydroxide (10%) | ◎ |

| Calcium hydroxide (10%) | ◎ |

| Hydrogen peroxide (3%) | ◎ |

| Chemical | Rating |

|---|---|

| Aqueous ammonia | ◎ |

| n-Heptane | △ |

| Toluene | △ |

| Ethylene dioxide | ◯ |

| Trichloroethylene | △ |

| Chloroform | ◯ |

| Acetone | ◎ |

| Methyl acetate water | ◎ |

| Ethyl alcohol | ◎ |

| Chemical | Rating |

|---|---|

| Gasoline | ◯ |

| Gas oil | ◎ |

| Kerosene | ◯ |

| Fuel oil | ◎ |

| Turpentine oil | △ |

| Engine oil | ◯ |

| Turbine oil | ◯ |

| Linseed oil | ◎ |

Test method (ASTM D 543-56T)

The test piece (75 mm×25 mm×10 mm) is left immersed in various chemical products for 7 days in an atmosphere of 23°C and 50% RH. It is then removed from the chemical product and left at 35°C for 24 hours. The changes in dimensions and mass are then measured.

Rating

| Rating | Dimensional change rate (%) | Chemical absorption rate (Vol %) | Appearance |

|---|---|---|---|

| ◎ | < 1 | < 3 | No change |

| ◯ | 1 〜 3 | 3 〜10 | Little change |

| △ | > 3 | > 10 | Swelling |

| × | Dissolution or contraction |

Comparison of chemical resistance

| Chemical | MEF™ | Expanding polystyrene |

|---|---|---|

| Kerosene | ◯ | × |

| Engine oil | ◯ | × |

| Gasoline | ◯ | × |

| Toluene | △ | × |

| Trichloroethylene | △ | × |

| Acetone | ◎ | × |

| Methyl acetate | ◎ | × |

| Ethyl alcohol | ◎ | ◎ |

| linseed oil | ◎ | × |

Cold resistance of MEF™

Since the principal raw material used to make MEF™ is polyethylene, a foam product, resistance to cold is excellent.

Even at low temperatures, resistance to cracking and chipping is high.

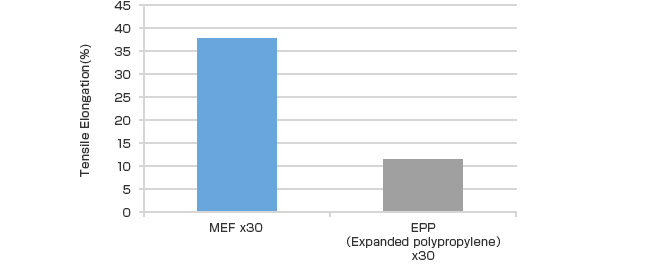

Tensile elongation rate at low temperatures (-30℃)

Note: The values in this table are measurement results; they are not intended as specifications.