Raw materials and method of manufacture

SunForce beaded foam, a product of Asahi Kasei's own plastic development and foaming processing technology, is the first such product in the world to be certified for high flame retardancy (UL-94 V-0).

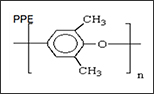

The primary raw material for SunForce is Asahi Kasei’s polyphenylene ether (PPE) plastic, an engineering plastic with excellent thermal resistance, flame retardancy, and electrical characteristics.

Thermoplastic plastics etc.

Flame retardant additives

Mixing and melt extrusion of

SunForce™ raw materials

Production of

mini-pellet

granules

Addition of

inorganic

gas

Foaming

SunForce™(foamed beads)

Our proprietary inorganic gas foaming technology uses foaming agents with extremely low environmental impact in the manufacturing process, with an extremely low VOC (volatile organic compounds) content even in the finished product.

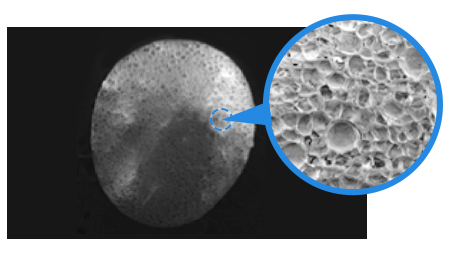

SunForce foam beads are manufactured solely for molding, with a smaller diameter than ordinary olefinic foamed beads and greater uniformity of shape. Unlike foamed beads using hydrocarbons as foaming agents, SunForce beads have no time limit for use.

The bubbles in the foam are closed-cell structures, and as such provide excellent thermal insulation and resistance to absorption of water.

Cross-section of foam beads