Environmental measures (Recycling and others)

Action for the environment

Production method

Unlike conventional foaming method with VOCs, inorganic gases are used in its production.

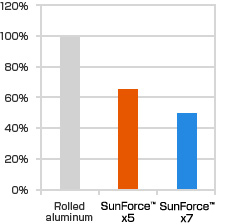

Comparison of weight at

the same flexural strength

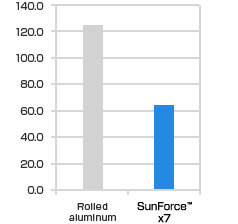

The total energy consumption

(MJ)

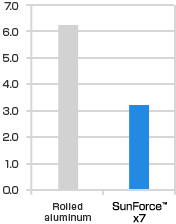

CO2 emissions

(CO2-kg)

Based on internal studies, SunForce is 40 to 50% lighter compared to an aluminum beam of the same bending strength.

The differences of environmental impacts during production of aluminum and SunForce are as follows:

- SunForce uses half of the total amount of energy for production of aluminum.

- SunForce emits only 3/4 of CO2 emission as compared to aluminum during production.

Data source :

- Aluminum :

- Rolled products (Including recycling material) :

‘Overview of rolled aluminum product LCI data‘,

Japan Aluminum Association, 2003

- SunForce™ :

- m-PPE “Survey of energy consumption of primary material”,

Institute for chemical research, 1993

NOTE: Energy for foaming process is estimated by AsahiKASEI.

Recycling

SunForce can be treated and recycled the same way as thermoplastic resins (melt and reuse as resins). It can also be used as an energy source by thermal recycling.

Material identification indication (ISO11469)>PPE+PS<

- HS code:

- Import and export harmonized system code 3921-19-900

- HS code:

- Code number based on International convention on the Harmonized Commodity Description Coding System