Microza contributes to solving global water resource issues

and the production of commercially important products

with its extensive lineup and high separation technologies

backed by long-term R&D efforts and experiences.

From our extensive lineup of over 100 hollow fiber membrane products, we offer the best proposal for your filtration purposes.

We provide Asahi Kasei’s Microza, which has high separation precision, for concentration and purification processes of a wide variety of industries, including pharmaceutical, food, bio, and chemical industries. We also provide manufacturing services for membrane filtration devices.

Microza is being used in water treatment plants all over the globe to solve water resource issues.

What is Microza?

Microza is a membrane filtration module containing hollow fiber membranes developed by Asahi Kasei in the 1970s. Liquid separation (= membrane filtration) is carried out using the pores on the surfaces of straw-shaped fibers. Characterized by pores on the membrane surface being uniform in size and shape, it achieves filtration performance of high durability, which is attained by Asahi Kasei’s original manufacturing methods, and sharp pore size distribution.

Asahi Kasei provides diverse services and membrane filtration application devices besides the two types of hollow fiber membranes, i.e. microfiltration (MF) and ultrafiltration (UF) membranes.Unlike throw-away filters, Microza is highly durable and needs to be replaced only once in several years.

Microza supports a wide range of industrial activities, including electronics, pharmaceutical, bio, food, chemical, automotive, tap water, wastewater, water recycling, power generation, and environment-related fields.

Scope of Microza (separation targets and fields)

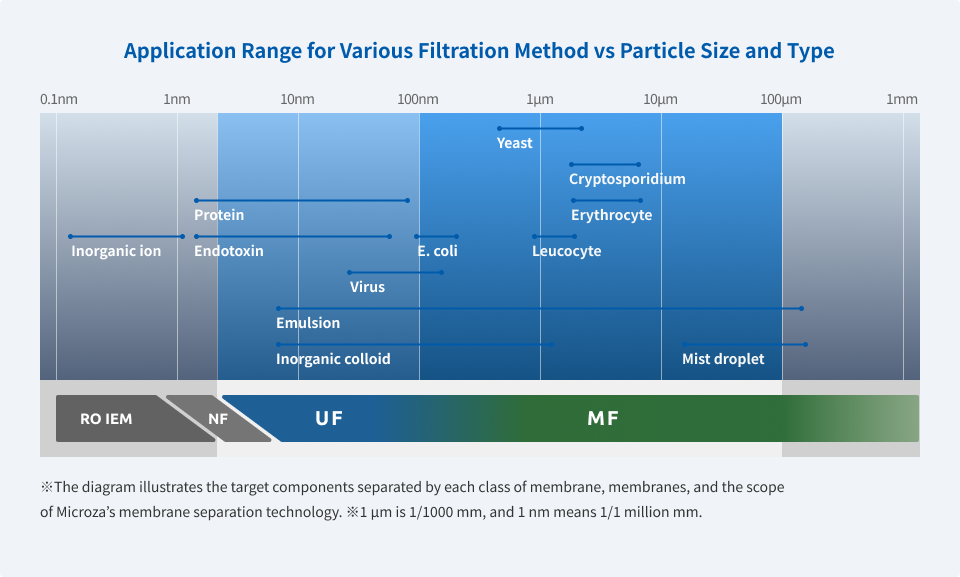

There are two major Microza lineups: ultrafiltration (UF) and microfiltration (MF) membranes. Sieving through the pores on the surfaces of hollow fibers, UF membrane can separate proteins and endotoxins, and MF membrane can be used to separate various microbial cell bodies and protozoa.

Reasons why Microza is chosen

Product lineup

Diverse products are available not only in terms of membrane material but also in terms of fiber inner diameter and fractionation/ pore diameter. Asahi Kasei offers more than 200 different products, so you can select the membrane filtration of the optimum specifications out of a very wide range of choices.

Filtration system design & manufacturing

Asahi Kasei is also offering designing and manufacturing services for membrane filtration devices as well as hollow fiber membranes. Sample testing at Asahi Kasei’s laboratory and lending of testing equipment is also possible depending on your purpose. From small-scale investigation to the installation of a commercial plant, Asahi Kasei’s engineer accompanies you and provides consistent support.

Customer Support after Installation

To realize the stable operation of Microza installations, technical support is provided by a Japanese or oversea engineer whenever necessary. Analysis of the used hollow fiber membrane is also available, facilitating you to find out the appropriate replacement period based on your filtration targets and operation conditions.

Contribution to SGDs

The deployment of Microza started in the production of water for injection (WFI) as an environment-friendly alternative for distillers, which emit a huge amount of CO2. Microza is also being used as a substitute for diatomaceous earth filtration, which produces large quantities of waste.

Microza is also widely used in various countries of the world in the process of recycling wastewater into industrial water by further purifying treated wastewater from sewage plants and industrial wastewater, greatly contributing to solving the water resource issue, which is one of the SDGs.