- Automotive painting

- Separation technology

Microza UF systems are widely used for paint recovery and closure of paint lines for electrodeposition coatings used in automobiles, home appliances, construction materials, etc.

Microza responds to various challenges in the autmotive painting application

Unstable filtration flow rate may cause the following issues:

Overtime work and working on a day off due to replacing UF modules

Unstable quality of the coating film

on products requiring coating repairing

reduce the costs of purchasing paint

Poor recovery of paint

resulting in high paint consumption

Why Microza?

Contributes to stable coating quality, cost reduction, and environmental preservation

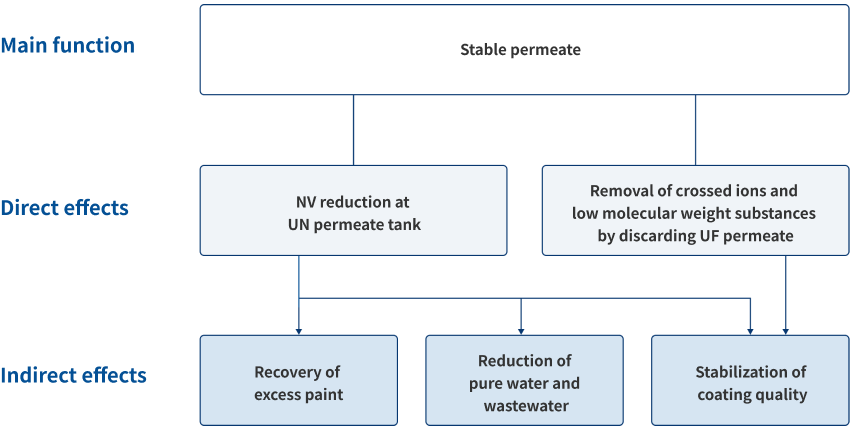

UF systems in the cationic electrodeposition process contribute greatly to the stable quality of coating film, cost reduction, and environment protection via recycling of solution used for rinsing coated articles, recovery of paint, reducing wastewater loads and electro-coating tank solution control. The importance of their roles has recently been recognized anew. The selection of a good-performance UF system is a topic in the cationic electrodeposition process. Microza UF membrane modules and systems contribute to the development of cationic electrodeposition with their highly completed hardware, polished by several implementations, abundant software technologies, and substantial aftercare services.

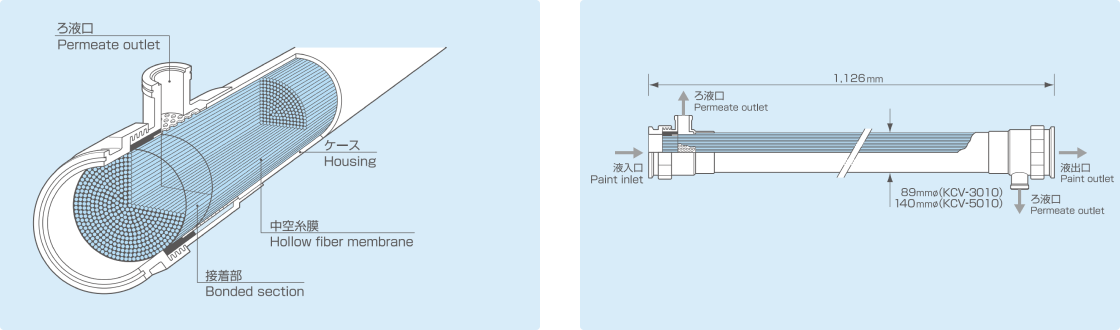

Module structure

Effects of UF introduction

Differences from other technologies

- Membrane material developed exclusively for cationic electrodeposition paintis employed, being feasible for diversifying electrodeposition paints.

- The UF modules arecompact and have high filtration capability.

- They are equipped witha backwashing system that actualizes excellent filtration stability.

Examples of applications in the field of electrodeposition painting

- Recovery of electrodeposition paint

- Electrodeposition coating line

- Recovery of paint, reduced wastewater load, reduced use of pure water

- Electrodeposition coating plant