About Dry Filters (SARAN SCREEN™ SARAN HONEYCOMB™)

Manufacturer

Manufacturer of Dry filters is Asahi Kasei Advance Corporation.

We are the provider of the original yarn.

For your contact we may our agent or manufacturer to contact you directly.

Types

Available with a mesh structure as SARAN SCREEN™,and with a honeycomb structure as SARAN HONEYCOMB™.

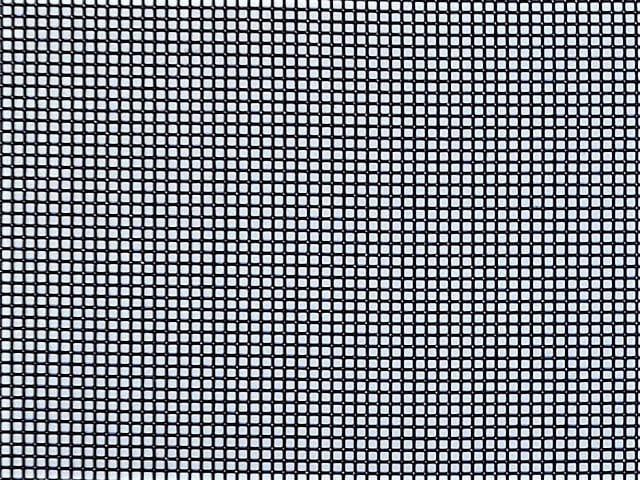

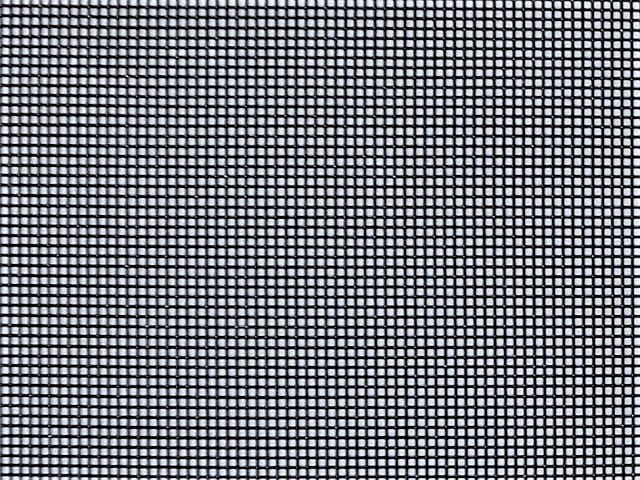

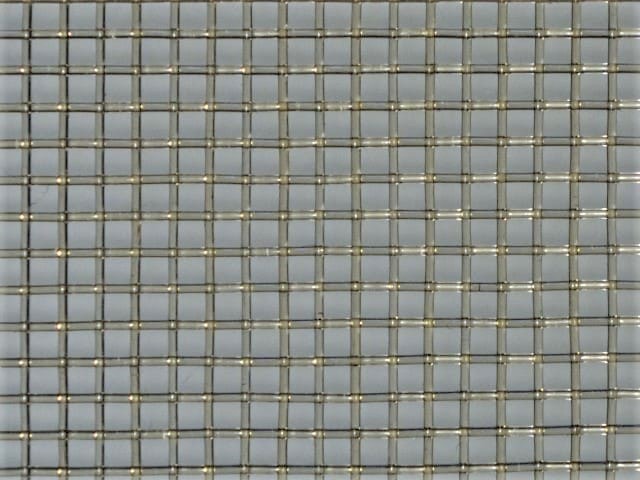

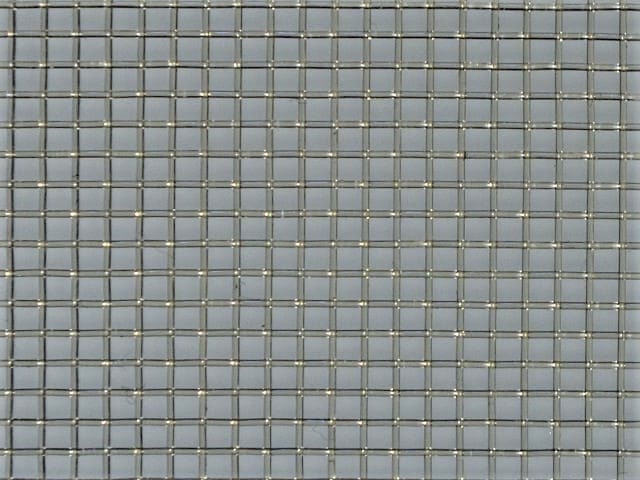

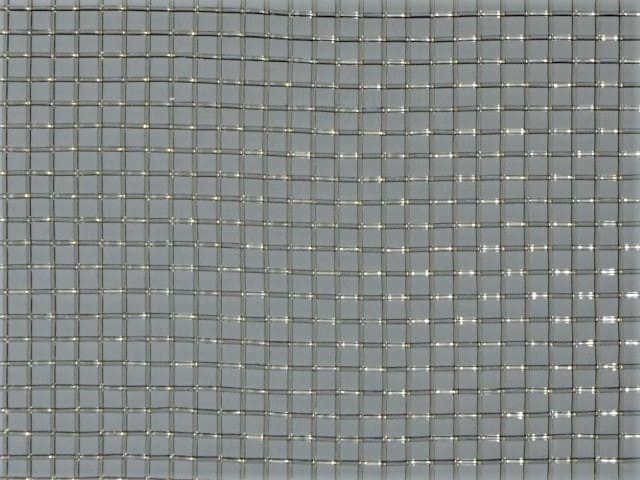

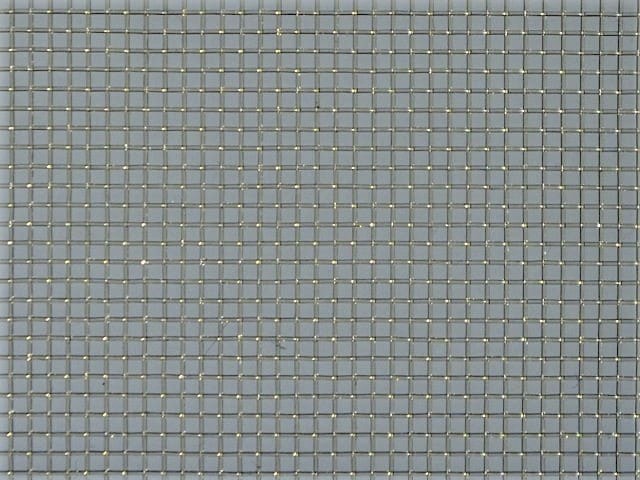

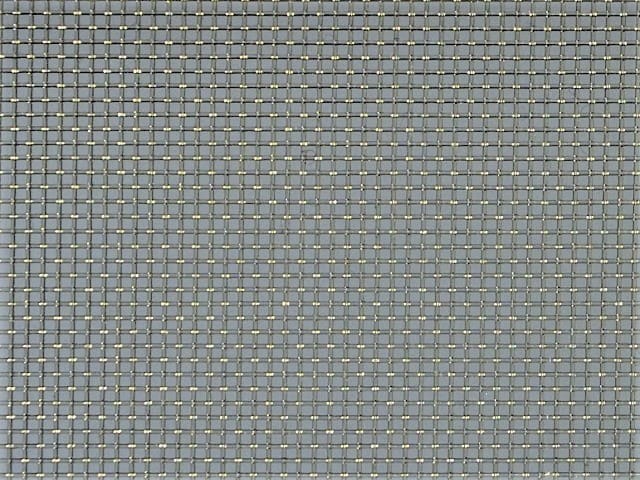

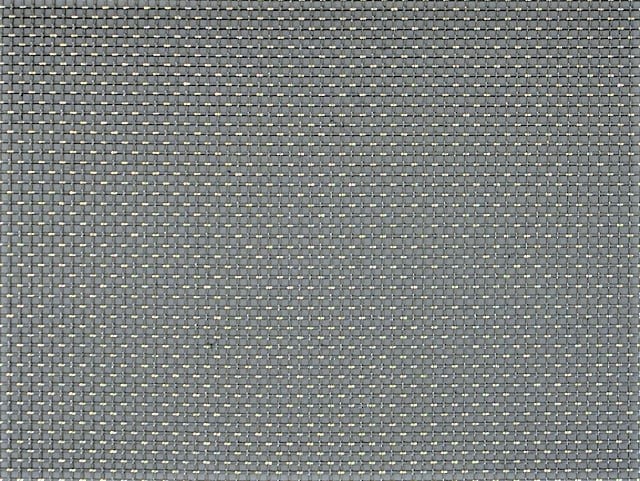

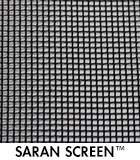

SARAN SCREEN™

Please click on the small image to enlarge it

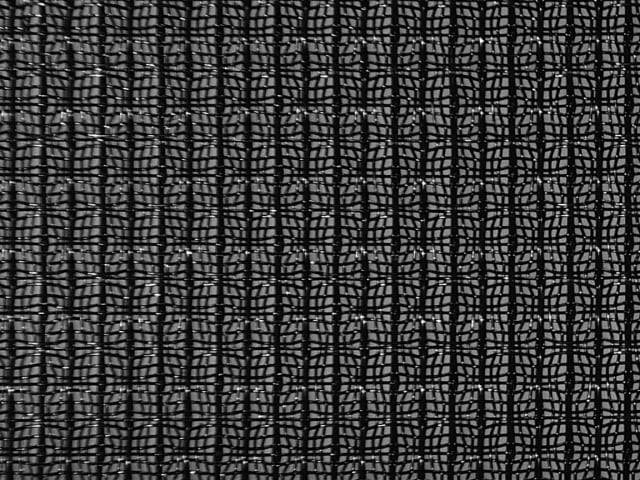

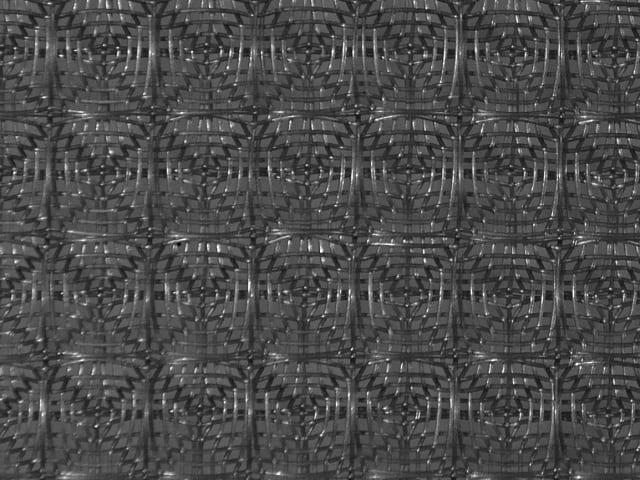

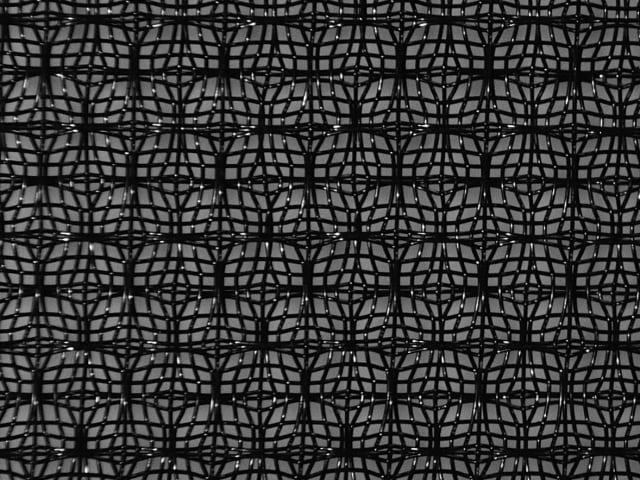

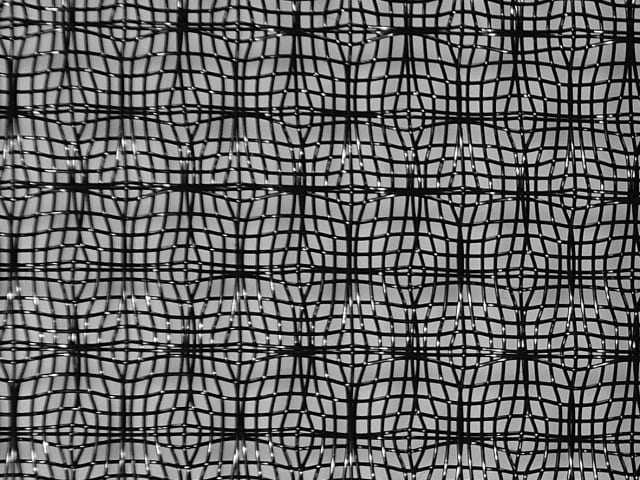

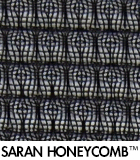

SARAN HONEYCOMB™

Processing example of SARAN HONEYCOMB™

Please click on the small image to enlarge it

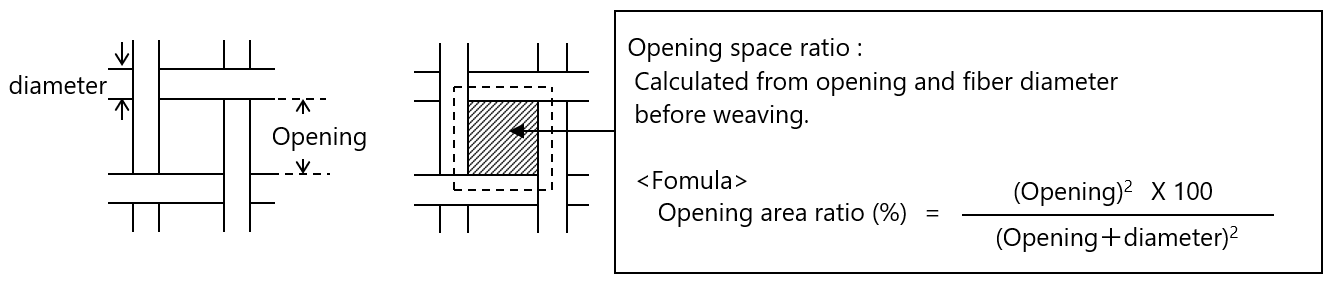

Physical properties and fiber diameter of

SARAN SCREEN™ and SARAN HONEYCOMB™

Specification

| Type | PN. | Width(cm) x length(m)* |

Fineness | Mesh / inch Warp / Filling |

Calculated value | ||

|---|---|---|---|---|---|---|---|

| Diameter (mm) |

decitex (denier) |

Opening (mm) |

Opening area ratio (%) |

||||

| SARAN SCREEN™ |

N-12 | 92×50 | 0.50 | 3300 (3000) |

12/12 | 1.62 | 58.3 |

| N-16 | 105×30 | 0.39 | 2000 (1800) |

16/16 | 1.20 | 57.3 | |

| N-20 | 105×30 | 0.29 | 1100 (1000) |

20/20 | 0.98 | 59.8 | |

| N-24 | 92×30 | 0.25 | 830 (750) |

24/24 | 0.81 | 58.3 | |

| N-32 | 92×30 | 0.25 | 830 (750) |

32/32 | 0.54 | 46.9 | |

| N-50 | 92×30 | 0.18 | 440 (400) |

50/50 | 0.32 | 40.9 | |

| B-24 | 92×30 | 0.24 | 780 (700) |

24/24 | 0.82 | 59.5 | |

| B-42 | 92×30 | 0.18 | 440 (400) |

42/42 | 0.42 | 48.6 | |

| B-50 | 92×50 | 0.16 | 330 (300) |

50/50 | 0.35 | 47.4 | |

| B-60 | 92×50 | 0.16 | 330 (300) |

60/60 | 0.26 | 39.3 | |

| SARAN HONEYCOMB™ |

811 | 125×30 | 0.24 | 780 (700) |

45/46 | - | - |

| 130 | 122×30 | 0.18 | 440 (440) |

78/54 | - | - | |

| 9600 | 122×30 | 0.24 | 780 (700) |

41/42 | - | - | |

| 9600-6 | 106×30 | 0.22 | 670 (600) |

40/35 | - | - | |

*approximated length

|