Flame-resistant fiber Lastan™

With an advancing, diversifying and aging of society, incidences of fire and human-made disasters increase, along with growing risks of related accidents.

With the formulation of the Product Liability Act, we are required to prevent the above-mentioned risks as much as possible.

Our flame-resistant fiber Lastan™ has high resistance to heat and flame.

In the event of an accident, it won't burn.

With various postprocessing processes, Lastan™ shields heat and flame, and as the most suitable material for the fire safety related area and industrial material area, it meets social needs and receives a high evaluation.

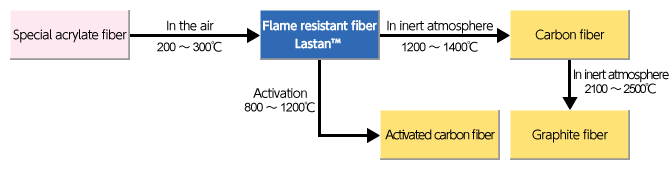

- Manufacturing process of Lastan™

-

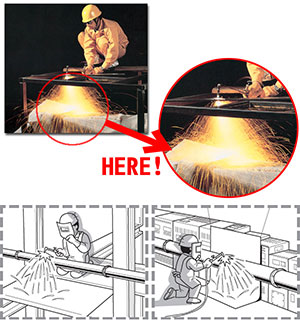

- Features of Lastan™ spatter sheet

-

- Fiber made from special acrylate fiber by carbonization-firing.

Uses fibers which have high resistance to flame and heat. - Higher flame resistance (LOI value) than the traditional flame-retardant fibers and heat resistant fibers.

- Even at high temperature or upon contact with flame, won't melt but will merely glow in the air.

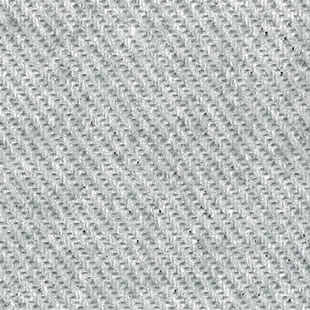

Excellent dimensional stability. - Lightweight fiber with a soft texture and causes no dust problems such as those caused by asbestos.

- High resistance to flame and heat against slag and sparks during welding or fusing processes.

Sheet which is resistant to tearing. - JIS A 1323 compliant product

- Fiber made from special acrylate fiber by carbonization-firing.

- Notes

-

- When heated for a long time at a high temperature, oxidation degradation can occur in the same way as with glass and asbestos.

- Because fibers are fired, black fibers can come off in some product types.

- Cannot be dyed.

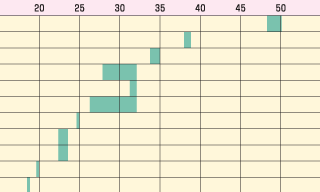

- Limited oxygen index of Lastan™

-

A higher limited oxygen index (LOI) means a higher resistance to flame.

Lastan™ is an organic fiber with excellent flame resistance.LOI

Lastan™ Carbonized while the current condition is preserved. PBI Novoloid Carbonized while the current condition is preserved. Aramid Softening, shrinking. Fireproof wool Modacrylic fiber Burning while being shrunk and fused. Wool Burning while being softened and sintered. Polyester Burning while being shrunk and fused. Nylon Burning while being shrunk and fused. Rayon Burning without softening and fusing. Cotton Burning without softening and fusing. * LOI (Limited oxygen index) JIS K 7201: Minimum oxygen volume fraction required to keep burning.

Applications of Lastan™ spatter sheet

- Product description

-

AS200S (Regular) Product image (indication) Width x Length 100 cm x 30 m (arbitrarily)

Thickness m/m 1.0(±0.2) Weight g/m 750(±80) Tensile strength

N/5 cm WidthVertical 1094 Horizontal 553 Tearing strength

NVertical 60 Horizontal 53 Tensile elongation

%Vertical 14 Horizontal 15 Coating Silicon based double side coating Japan Testing Center for Construction Materials

Flame retardant testing method for spark droplets of welding and gas cutting on fabrics sheets in construction work

JIS A 1323Type A compliant

No. 05A0009AS400S (Light) Product image (indication) Width x Length 100 cm x 30 m (arbitrarily)

Thickness m/m 0.8(±0.2) Weight g/m 400(±50) Tensile strength

N/5 cm WidthVertical 680 Horizontal 377 Tearing strength

NVertical 36 Horizontal 35 Tensile elongation

%Vertical 13 Horizontal 14 Coating Silicon based single side coating Japan Testing Center for Construction Materials

Flame retardant testing method for spark droplets of welding and gas cutting on fabrics sheets in construction work

JIS A 1323Type C compliant

No. 05A0011

- Example applications

-

- Sheet for welding

- Sheet for gas cutting

- Sheet for construction work

- Sheet for electrical work

- Curtain for furnace front

- Heat insulating curtain

- Apron for furnace, etc.