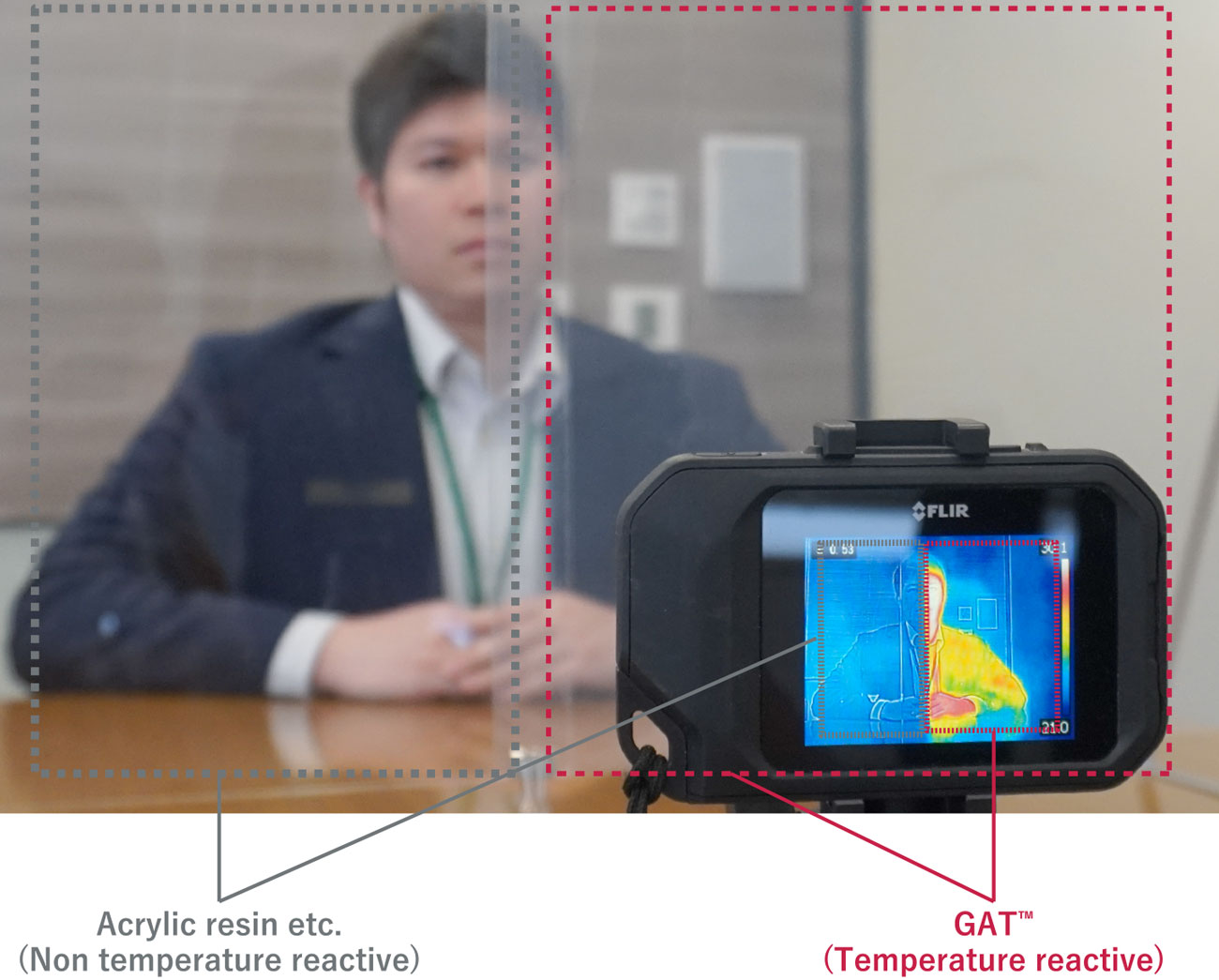

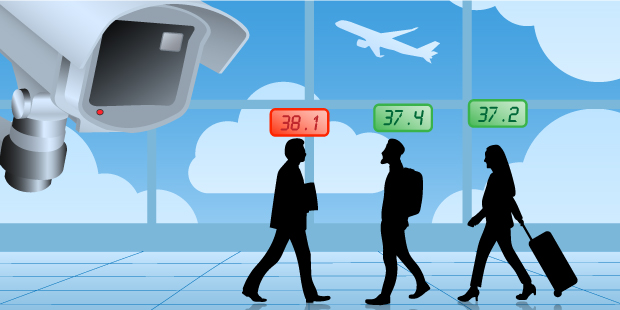

GAT™ can also be used as a sneeze guard to prevent droplet infection.

Since GAT™ transmits both “Visible” and “Infrared” rays, it can be used as a sneeze guard to both

Measure Body Temperature with an infrared camera and

Prevent Droplet Transmission.

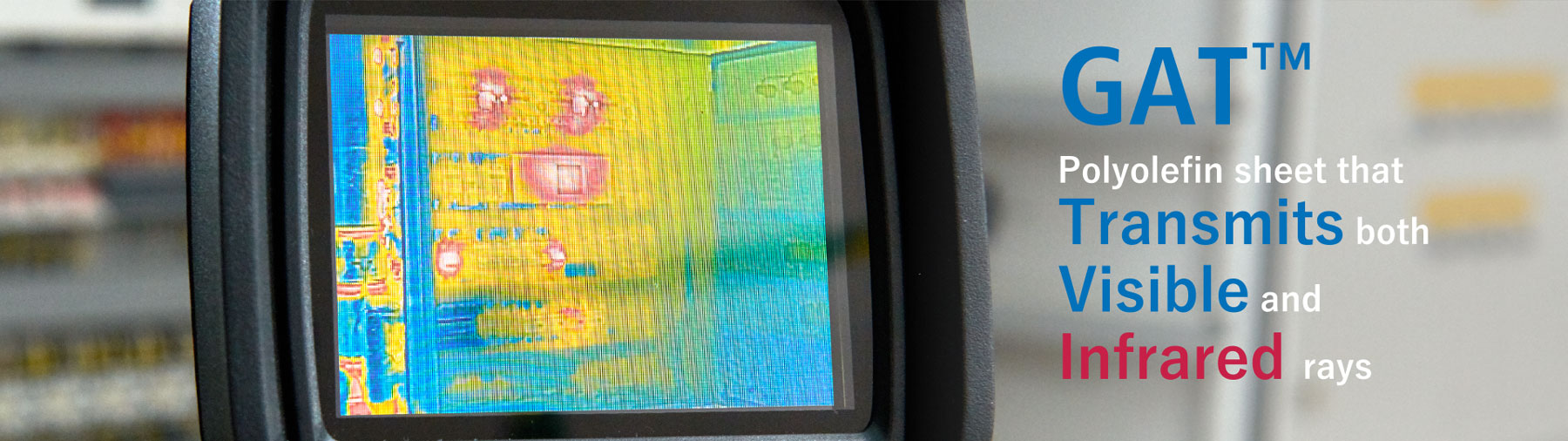

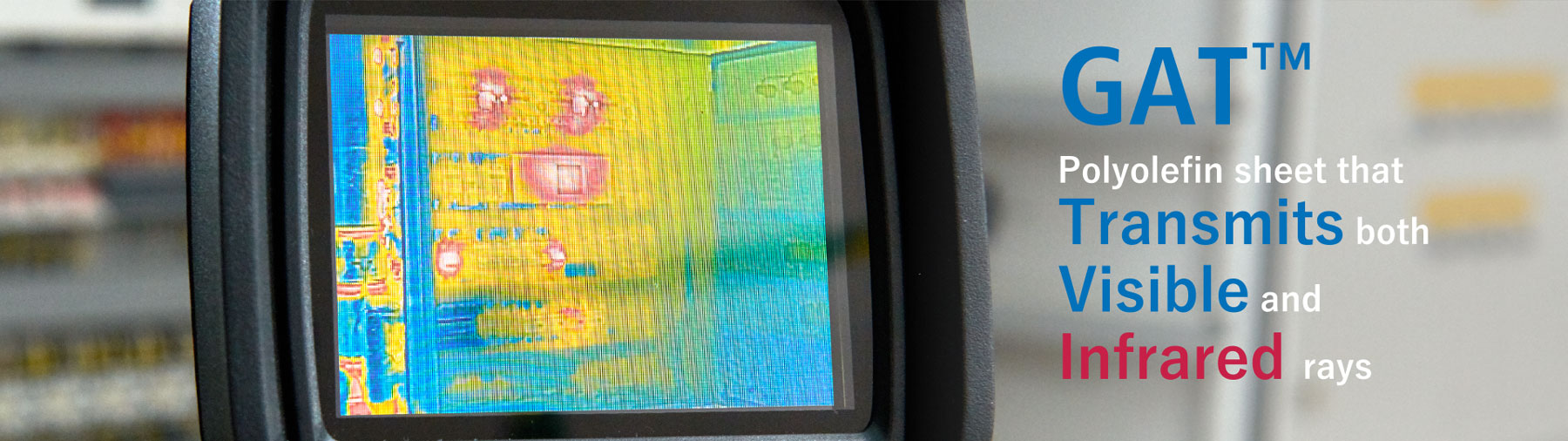

About GAT™

Infrared Transmissive Transparent Sheet “GAT™” is a polyolefin sheet that transmits both "visible ray" and "infrared ray" at the same time through our unique technology.

This enables us to perform both visual inspections and infrared thermography inspections of electrical equipment at the same time.

Visual Inspection

GAT™

Acrylic resin

Infrared Thermography Inspection

GAT™

Acrylic resin

GAT™

Acrylic resin

Example of use

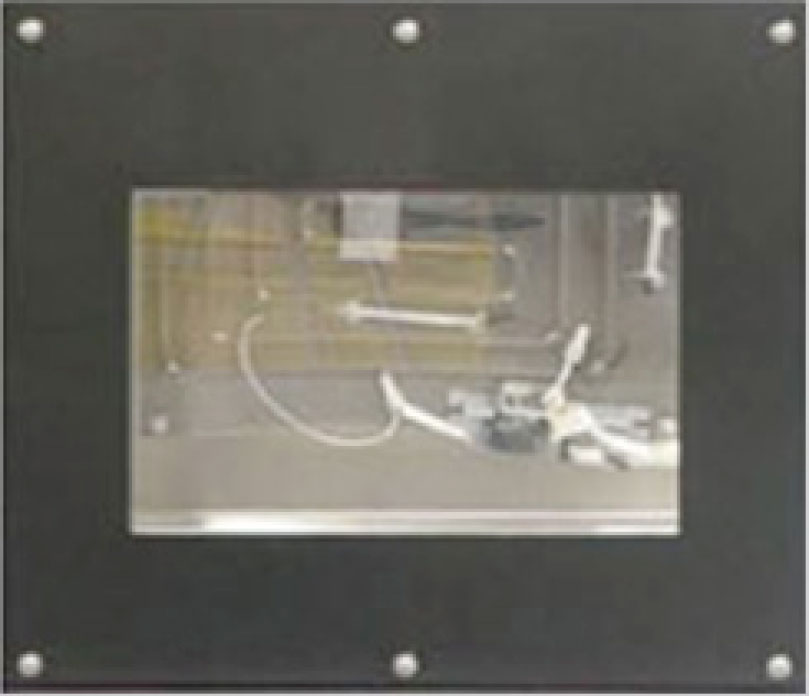

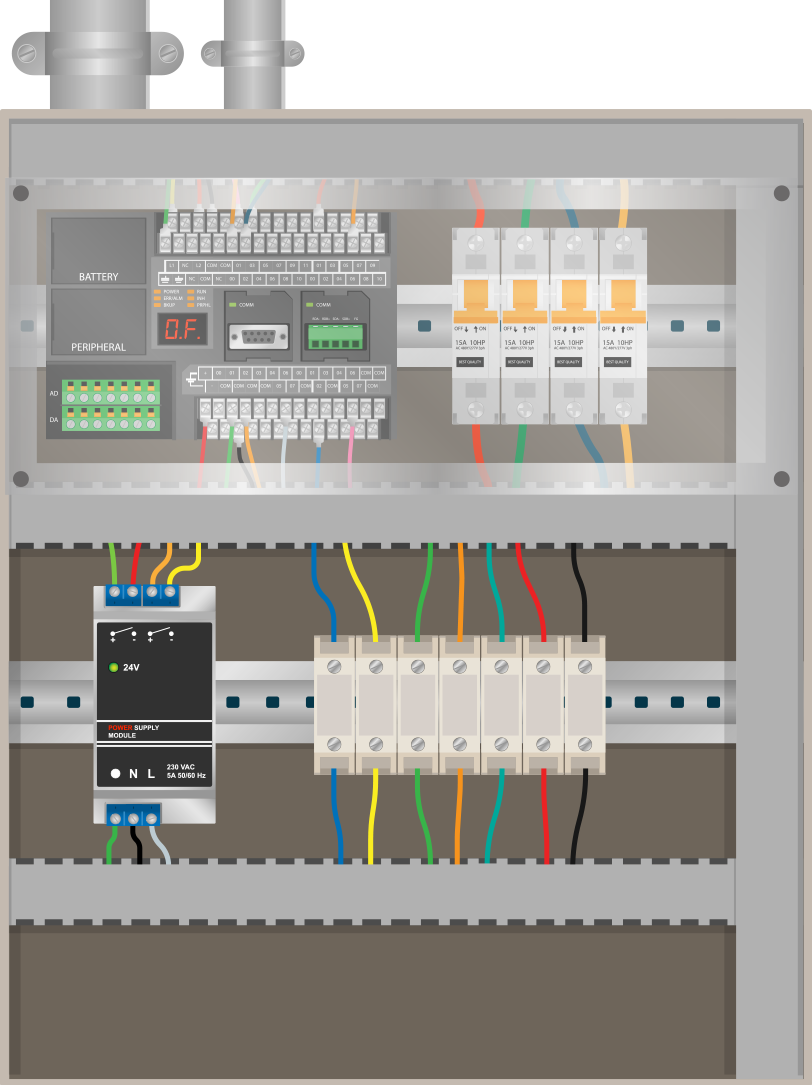

Insulation protection cover for monitoring in distribution boards

In order to prevent electric shock to workers, distribution boards and control panels are equipped with protective covers made of transparent resin (acrylic resin or PVC).

Traditional transparent resins such as acrylic resin can be visually inspected, but infrared rays cannot penetrate through them, so infrared thermography inspections could not be performed through the protective covers.

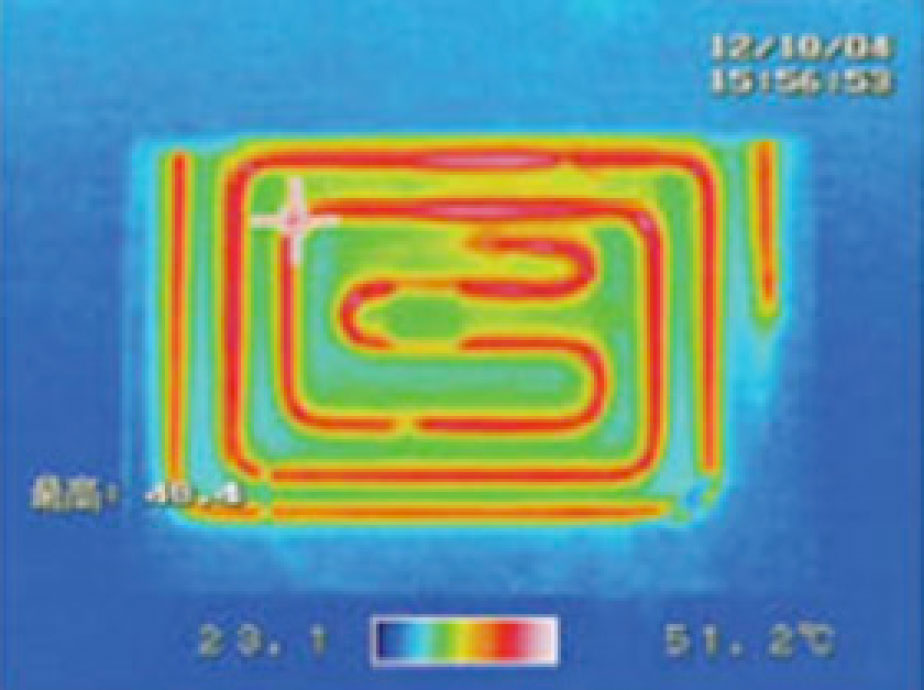

By using GAT™ as a protective cover, visual inspection and infrared thermography inspection can be performed simultaneously.

Application examples for distribution boards

Application examples for distribution boards - Infrared thermography inspection

Underneath the acrylic cover the thermal image cannot be seen because the infrared radiation does not penetrate the cover, whereas the GAT™ cover shows the internal thermal image.

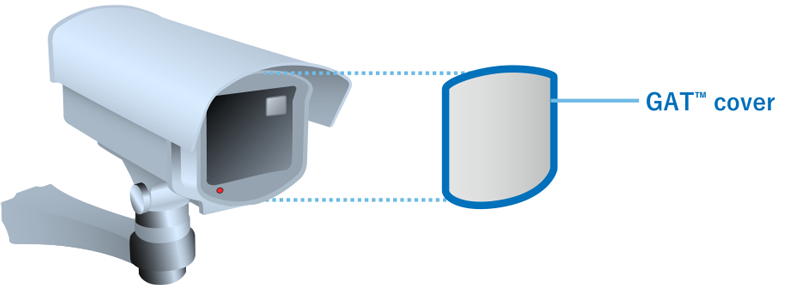

Lens protection cover for infrared cameras

It can be used as a cover to protect the lens when shooting with an infrared camera.

GAT™cover

The GAT™ cover can be used as a protective cover to avoid damage to the lens of the infrared camera due to breakage of the object being photographed.

Advantages

Prevention of fire accidents

The early detection of abnormal heating points

reduces the risk of fire accidents.

24-hour monitoring

24-hour condition monitoring with an infrared camera makes it possible to detect and react to abnormal heating and other conditions at an early stage.

Safer inspections

As it is not necessary to remove the protective cover inside the distribution board, it is possible to prevent injuries due to the removal of the protective cover and electric shocks due to contact with the current-carrying parts, making inspections safer.

Efficient inspection

By eliminating the need to remove the protective cover inside the distribution board, infrared thermography inspections can be carried out more efficiently due to reduced measurement time.

Competitive edge

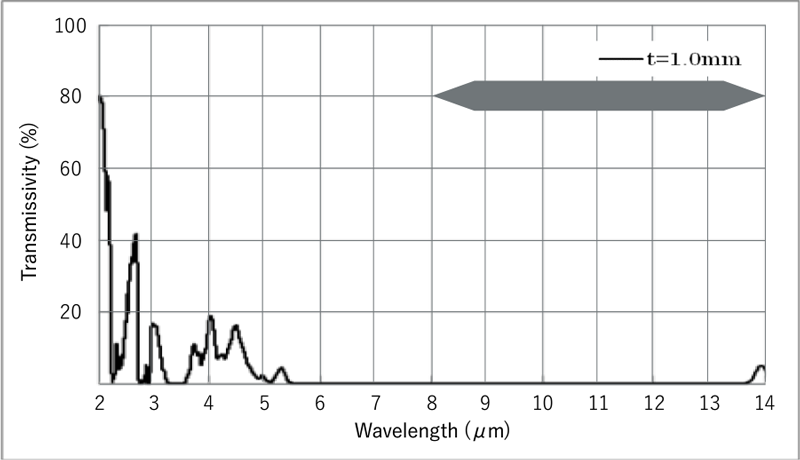

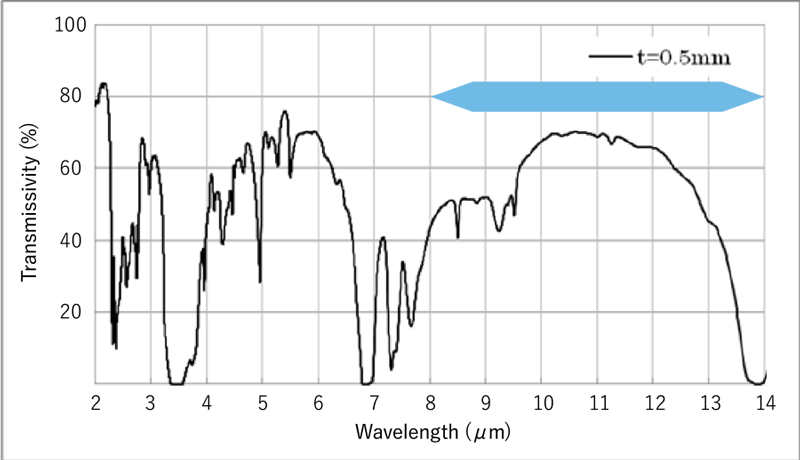

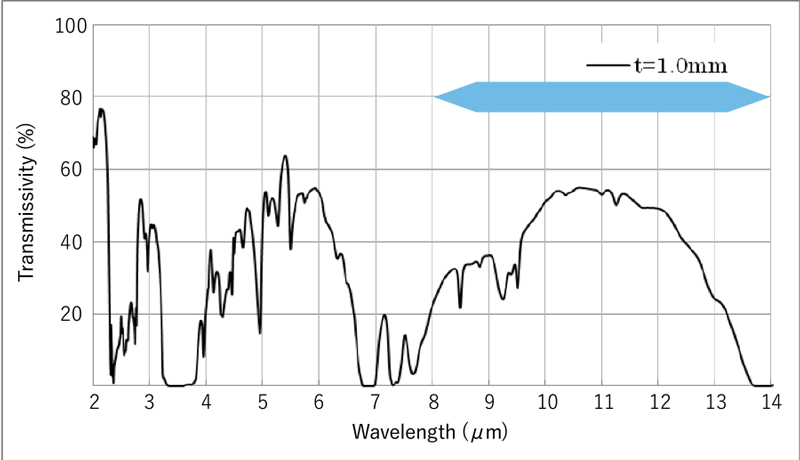

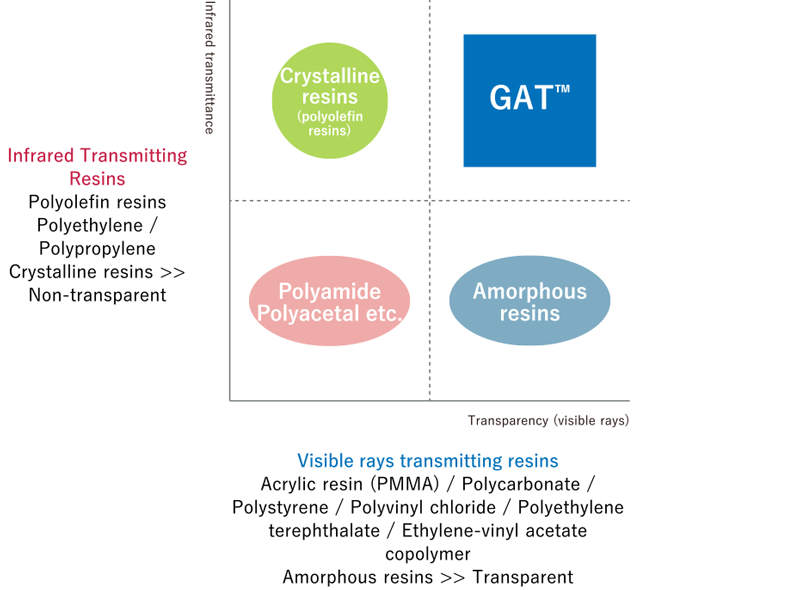

Comparison with other resins

Sheet that transmits both visible and infrared rays.

Comparison with other materials

GAT™ is an excellent material in terms of both infrared and visible light transmission and ease of use.

| Acrylic resins (PMMA) | Quartz glass | Polyethylene | GAT™ | |

| Infrared transmittance |

Poor | Fair (Far infrared ray is poor) | Good | Good |

| Visible light transmittance |

Excellent | Excellent | Fair 〜 Poor | Good |

| Cost | Excellent | Poor | Excellent | Good |

| Specific Gravity | Fair | Poor | Excellent | Excellent |

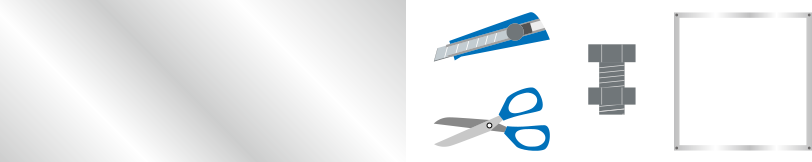

Installation

GAT™standard products can be modified to suit your needs.

Required components

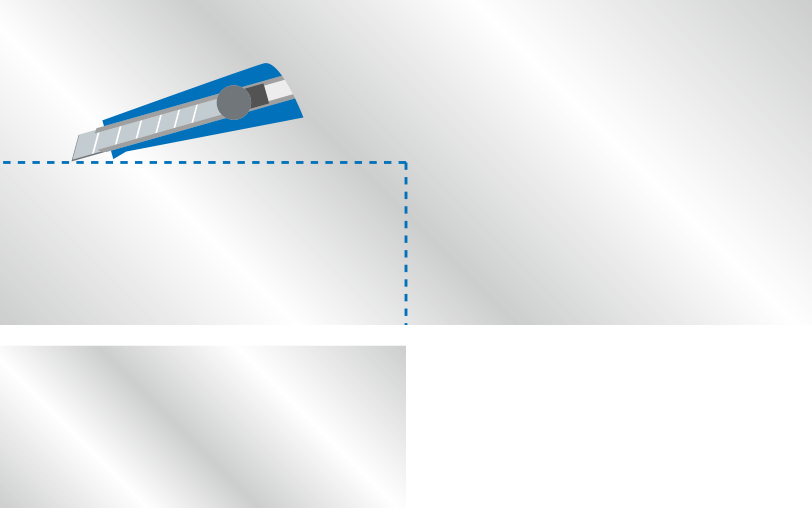

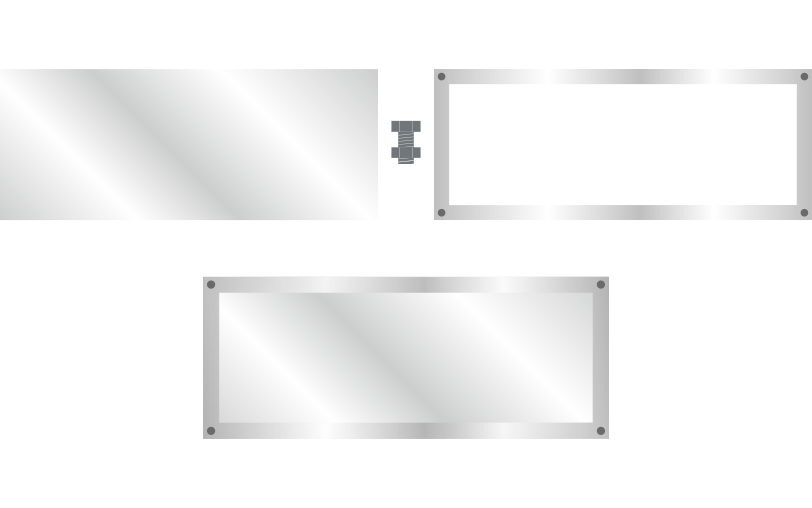

Step1

Step2

Step3

GAT™ standard products

Cutters/scissors (for cutting GAT™), Frame material (acrylic (PMMA), aluminum, etc.), Screws (for fixing GAT™ to frame material)

Cut out the required size from the GAT™ standard product using a cutter/scissors etc.

Fix the cut-out GAT™ to the frame using screws.

Attach the frame with the GAT™ to the required position. Please prepare the mounting brackets etc.

Specifications

| Specification items | Specifications | ||||

| Product number | GAT-05 | GAT-10 | |||

| Available sizes | Width x Length |

400mm x 1000mm |

400mm x 500mm |

400mm x 1000mm |

400mm x 500mm |

| Thickness | 0.5mm | 1.0mm | |||

| Price | Please contact us for prices | ||||

| Chemical or General Name | Polyolefin | ||||

| Melting point | 248〜284℉ (120〜140℃) | ||||

| Recommended working temperature for stable use | 176℉ or less (80℃ or less) | ||||

| Density | Less than 1,000kg / ㎥ | ||||

| Recommended use | Mainly used for protective cover sheets for power supply panels | ||||

Please contact us for sizes other than the above.

Physical properties

| Type |

Item | Unit | Standard | GAT-05™ | GAT-10™ | |||

| MD | TD | MD | TD | |||||

| Mechanical Properties | Tensile stress at yield | MPa | ISO-527-3 | 82.3 | 31.9 | |||

| Tensile strain at break | % | ISO-527-3 | 64 | 320 | ||||

| Tensile modulus | MPa | ISO-527-3 | 1,510 | 2,380 | ||||

| Flexural modulus | MPa | JIS-K7171 | 985 | 1,690 | ||||

| High speed tensile strength (0.05m/sec.) | MPa | JIS-K7171 | 138 | 35.4 | ||||

| High speed tensile strength (0.5m/sec.) | MPa | JIS-K7171 | 156 | 36.9 | ||||

| High speed tensile strength (5m/sec.) | MPa | JIS-K7171 | 202 | 92.7 | ||||

| High speed tensile elongation at break (0.05m/sec.) | % | JIS-K7171 | 26 | 5.7 | ||||

| High speed tensile elongation at break (0.5m/sec.) | % | JIS-K7171 | 20 | 3.2 | ||||

| High speed tensile elongation at break (5m/sec.) | % | JIS-K7171 | 13 | 2.3 | ||||

| Tear strength | N/mm | ISO-6383-1 | 3.65 | - | 5.55 |

- | ||

| Average tear strength | ISO-6383-1 | 2.06 | - | 5.9 | - | |||

| Rockwell hardness (R) | HRR | K7202-2 | 81 | |||||

| Rockwell hardness (HRR) | HRR | ISO-2039-2 | 55 | |||||

| Impact resistance by the dart method | Kg | JIS-K7124-1 | >2.0 | |||||

| Thermal Properties | Softening temperature (0.5N,5℃/min.) | ℃ | JIS-K7196 | 100 | ||||

| Electrical property | Volume resistivity | ρv(Ω・cm) | IEC-62631-3-1 | >4×1015 | 5 | |||

| Dielectric breakdown voltage | KV/mm | IEC-60243-1 | 80 | |||||

| Frictional electrification | Τ(sec) | JIS-L1094 | >120 | |||||

| Relative permittivity (10KHz) | ε | IEC-62631-2-1 | 2.31 | |||||

| Relative permittivity (1MHz) | ε | IEC-62631-2-1 | 2.31 | |||||

| Relative permittivity (100MHz) | ε | JIS-C2138 | 2.4 | |||||

| Relative permittivity (1GHz) | ε | JIS-C2138 | 2.4 | |||||

| Dissipation factor (10KHz) | tanδ | IEC-62631-2-1 | 0.0002 | |||||

| Dissipation factor (1MHz) | tanδ | IEC-62631-2-1 | 0.0002 | |||||

| Dissipation factor (100MHz) | tanδ | JIS-C2138 | 0.001> | |||||

| Dissipation factor (1GHz) | tanδ | JIS-C2138 | 0.001> | |||||

| Flammability | Arc resistance | sec | JIS-C2135 | 162 | 1 | |||

| Flammability | UL94 | HB | ||||||

| Optical Properties | Luminous transmittance | % | JIS-K7361-1 | 88.6 | 86.2 | |||

| Haze | % | JIS-K7136 | 5.7 | 9.8 | ||||

| Refractive index | % | JIS-K71426 | 1.518 | |||||

| Chemical Resistance | Acidity (room temperature) | - | - | good | ||||

| Alkalinity (room temperature) | - | - | good | |||||

※ Data shown here are typical valuses and not quality assuarance values.

FAQ

Q: In which applications are the GAT-10 and GAT-05 used?

A: GAT-10 is often used as a protective cover for distribution boards, switchboards and control panels where a certain degree of strength is required.

GAT-05 is often used as a protective cover for sensors that require a certain degree of transparency.

Q: Is it possible to sell larger sizes than 400mm wide x 1000mm long?

A: Basically, the maximum size is 400mm (width) x 1000mm (length), but the length will be negotiable depending on the quantity of lots.

However, please note that the width of 400 mm cannot be changed due to the manufacturing facilities.

Q: What are the freight charges?

A: The quoted price does not include the freight.

Q: How long does it take from order to delivery?

A: If the product is in stock, it can be shipped in about two weeks after receiving the order.

Please contact us.

Q: What is the minimum lot size?

A: The minimum order quantity for both GAT-10 and GAT-05 is 5 pieces.

Q: Do I need any special tools to process GAT™?

A: Use common industrial tools such as scissors or cutters.

However, please be careful when processing GAT™ as it is easily scratched (protective film is applied on both sides when delivered).

Q: Are there any recommended adhesives for fixing GAT™ to acrylic sheets, etc.?

A: There are no recommended adhesives for GAT™.

We recommend using screws to fix the GAT™ to an acrylic plate.

Q: Is it possible to make custom-made products with a thickness of 1.0 mm or more?

A: Currently, only 0.5 mm and 1.0 mm are available.

Please note that thicker thickness may cause clouding of GAT™ or decrease in infrared transmittance.

※ Please note that contents on this site may be updated for improvement without prior notice.