Production

Reducing CO2 emissions via renewable energy and introducing a closed-loop system,

we have established the environment-friendly and traceable production system.

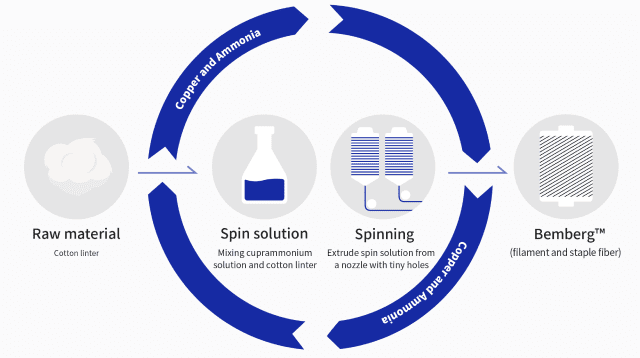

Closed-loop system

Bemberg™ is a regenerated cellulose fiber made from cotton linter. Since our foundation, we strictly control the chemical substances used in the manufacturing process. We have introduced a closed-loop production system that recovers and reuses copper and ammonia. We have been making improvements further even now.

Initiatives for carbon neutrality

GHG emissions—Goals of Asahi Kasei Group

- By 2050

- carbon neutral

- By 2030

- emissions reduction of 30% or more (from fiscal 2013)*Scope 1 (direct GHG emissions) and Scope 2 (indirect emissions use of electricity, heat, and steam supplied by other companies), absolute quantity

Energy decarbonation

Since the foundation, we have been in the business of transmitting electric power from our own hydroelectric plants, and currently own nine power stations in total.

By improving the efficiency of these generators, we will reduce CO2 emissions by approximately 11,000 tons annually and aim to further reduce the environmental impact.

Asahi Kasei’s hydroelectric power plants: Nine stations (the oldest facility is from 1925)

Photo: Gokasegawa Power Station

We installed a biomass power generation in 2012 to increase renewable energy ratio. We replaced a coal power plant with a natural gas (LNG) power plant, which has been in operation since March 2022.

Circularity

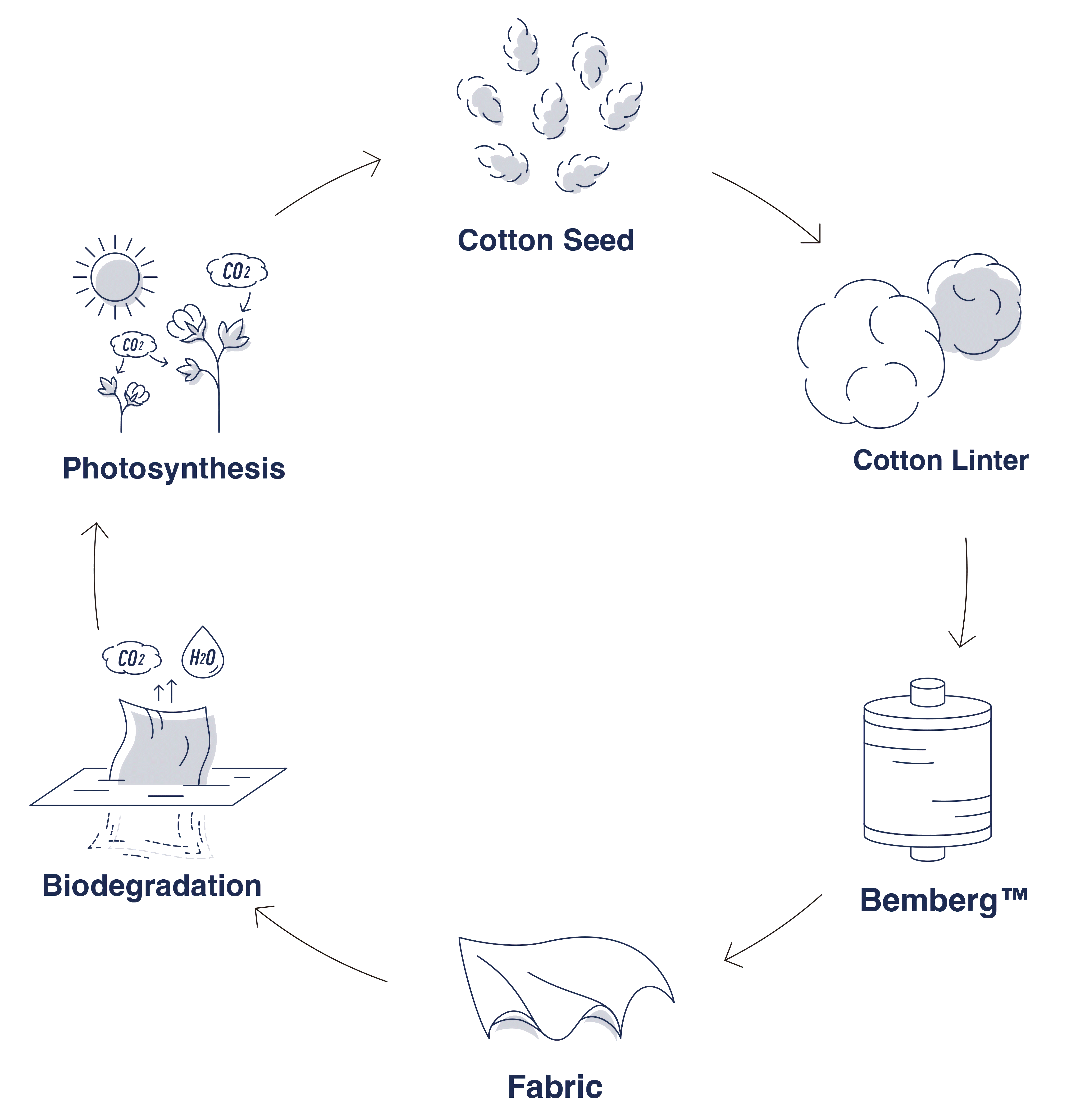

Cotton linter, the raw material for Bemberg™, is a byproduct of cottonseed oil derived from cotton plants that grow by utilizing carbon dioxide naturally present on the earth's surface.

Bemberg™ is decomposed by microorganisms into water and carbon dioxide, which are then reused in the photosynthesis process of cotton plants. In this way, Bemberg™ takes part in natural circularity and serves as an environmentally conscious material which contributes to reducing environmental burdens.

An example of Bemberg™