Bemberg™’s Actions in India

Cooperating with the Indian textile industry, we pursue through our business solutions to the social issues faced by India.

Making our efforts valuable to both the Indian textile industry and Asahi Kasei

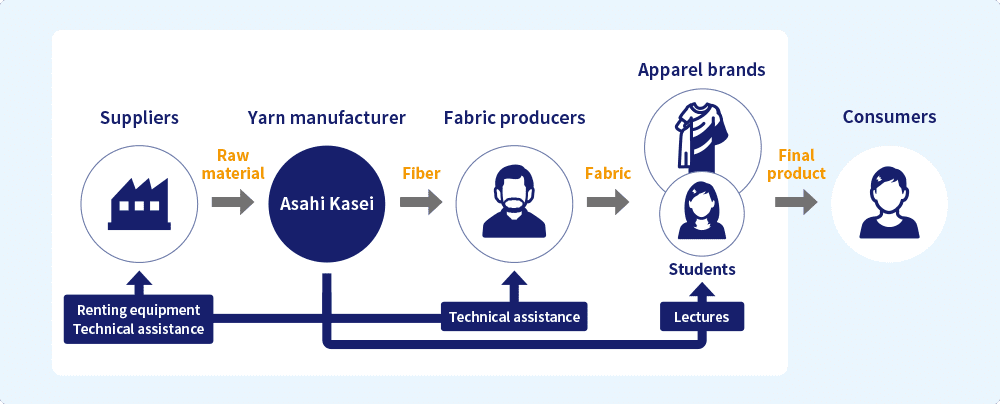

Beyond selling yarn, Asahi Kasei is undertaking many different initiatives throughout the supply chain, from raw materials to final products. These efforts help to increase the income of workers and produce solutions to social issues such as the empowerment of women in society. We also believe they benefit Asahi Kasei’s operations in terms of its ability to innovate and obtain new customers. Here are some examples of Asahi Kasei’s efforts in the Indian textile industry.

Industry-academia cooperation

Supporting education through Bemberg™

We support the education of the students and young people who will lead the Indian textile and fashion industries. With the goal of improving students’ knowledge and skills, we collaborate with academic institutions and contribute to the development of future of the industry.

Cooperating institutions: NID, NIFT (Mumbai and Bengaluru) and DKTE — See below for more information about the institutions.

Asahi Kasei contributes to achievement of Sustainable Development Goals (SDGs).

Related SDGs

Background

The History of the Bemberg™ business in India dates back more than 40 years. Bemberg™ is used in many traditional types of clothing, such as dupatta and saree. While silk and cotton are widely known, other clothing materials have not been clearly differentiated for retailers and consumers. At the same time, the visibility of Bemberg™ and cupro, the generic name of Bemberg™, is still low in India. This is partly due to a lack of public awareness of the material as a textile product and its percentages, as many clothes available in India have no tags to indicate quality-related information like you would typically see in Japan and Western countries. Because of this, Asahi Kasei has set goals. First, direct people’s attention to the materials that clothes are made from. Second, teach them about Bemberg™ so that this knowledge can be applied in manufacturing in the textile and fashion industries.

As in many other countries, women account for a large percentage of the students majoring in garment design. So, our goal is also to encourage these women to build their career in society through their activities at fashion colleges.

producing-area, Surat

Our activities and track record

Industry-academia cooperation should be meaningful for both students and Asahi Kasei. To this end, we do more than just present lectures from Asahi Kasei: the programs also includes the students’ presentation of their work and assignments that provide opportunities for them to learn from each other.

- ■NID and NIFT Mumbai

- Asahi Kasei began working with these institutions in 2016 and has focused on lectures about Bemberg™. We also arranged a visit to Surat, a major Bemberg™ production center, as an extracurricular event. We have continued meaningful activities encouraging the students to apply the things they’ve learned about materials to their work. For example, students have use Bemberg™ yarns to hand-weave projects based on the knowledge gained from the lectures.

In 2017, NID and NIFT Mumbai held fashion shows for their graduating students, with Asahi Kasei as the main sponsor. Students presented wonderful collections made from Bemberg™.

The collaboration with NIFT started with its Mumbai school. In 2018, we also began lecturing at NIFT Bengaluru. The activities have developed and we have become comprehensively involved with NIFT, a fashion education institute with campuses in major Indian cities.

- ■DKTE

- The first materials lecture about Bemberg™ was held in 2018. DKTE, primarily a training institute for the textile industry, educates students on the characteristics of Bemberg™ in an effort to improve their skills for workplaces engaged in weaving and other practices. Based on the knowledge about Bemberg™ obtained from the lectures, students experimented with weaving cloth and met to discuss their experiences.

Results for Bemberg™

Lectures at NID and NIFT have continued since 2016. Collaboration with DKTE started in 2018. These collaborations have gradually increased the visibility of Bemberg™ and Asahi Kasei’s activities in India. Moreover, our relationships with the schools have grown stronger. The young students are full of ideas and are capable of analyzing materials in fresh ways that may even lead to the development of new applications. They also give Asahi Kasei a lot to learn from. Indeed, these industry-academia collaborations are bearing fruit.

Contribution to society

Today, sustainability is one of the most important issues in the textile industry and it draws the attention of educational institutions and their students. By learning about Bemberg™, an environmentally responsive material, and using it in their work, students have meaningful opportunities to discuss the sustainability efforts that the world requires. Learning about sustainability supports the eco-friendly development of the industries. Communicating information about the trends of textiles in Japan and Western countries nurtures students’ awareness of international culture and creates opportunities to cross-culturally learn about the industry.

The core of the industry-academia cooperation in India is the development of young talent that will lead the textile and fashion industries in the future. The ability to gain more customers through the greater visibility of Bemberg™ materials will also support the weavers involved in the production of Bemberg™ in India.

Industry and academia in India: Institutions

NID (National Institute of Design): Located in Ahmedabad, NID is a national design college representative of India. It engages in industry-academia cooperation focused on students who major in textiles and garment design.

NIFT (National Institute of Fashion Technology): A national education institution specializing in fashion design, NIFT has campuses in major cities in India such as Delhi and Mumbai and many of its graduates, mainly designers, are active in the apparel industry.

DKTE (Dattajirao Kadam Technical Education Society): DKTE is a college of textile technologies and located in Ichalkaranji, Kolhapur, an area called “Manchester in the State of Maharashtra” that hosts a flourishing textile industry. The institute develops technical experts and is highly capable of advanced education in weaving, material processing, machine engineering and other subjects.

Technical assistance for fabric producers

Improve both our product quality and fabric producers’ skills and profitability

By sending technical experts and organizing material development seminars, we are committed to achieving the improvement of local producers’ skills, securing steady income for them, and other goals.

Asahi Kasei contributes to achievement of Sustainable Development Goals (SDGs).

Related SDGs

Background

The state of Gujarat is the center of the Indian textile industry, and an important market selling 4,000 tons of Bemberg™ annually. As it lags behind developed countries in advanced technologies, however, only a limited selection of fabric types can be produced in Gujarat and there are quality inconsistencies. In addition, many textile businesses in Gujarat are small in scale and have limited opportunities and funding to introduce advanced technologies. This has discouraged technological innovation and led Asahi Kasei to take action and utilize its accumulated expertise in Gujarat. We have established the goal of ensuring the evolution of both the material producers and Asahi Kasei in the ever-growing Indian market.

Our activities and track record

Asahi Kasei has sent its experienced technical experts to India to provide continuing technical guidance on material production using Bemberg™. Beyond stabilizing the material’s quality to ensure customer satisfaction, we reduce unnecessary waste and contribute to the enhancement of production efficiency. Meanwhile, we regularly gather textile producers at seminars about the development of materials and offer ideas for new products. For example, seminars introduce the many different kinds of fabrics that Asahi Kasei makes experimentally in Japan and the latest fashion trends for the Indian market. We also aim to increase workers’ wages by nurturing fabric producers’ capability of developing products that satisfy many different needs and by helping to increase their profits.

Since 2000 when the efforts began, the quantity of Bemberg™ sold by local producers has increased nearly six-fold. Our activities have taken on greater meaning to bring a profit to the local fabric producers.

Results for Bemberg™

Qualitative improvements of the materials produced by local producers and a greater variety of materials enhances the value of Bemberg™ as a brand. The increased use of Bemberg™ materials by apparel companies is another significant result.

Contribution to society

Our activities raised the quality of fabrics and made it possible to deliver higher quality products to Indian consumers.

Enhancing material producers’ technical and developmental skills can be expected to increase sales, profitability and the variety of merchandise available. The improvement of business performance stimulates new hiring in India.

In addition to wage increases following the improvement of a company’s profitability, workers can expect their improved skills to result in wage increases. These trends work to train the younger workforce and contribute to lasting technical improvement of material production areas in India, including improvements in their labor environments.

Technical assistance for raw material suppliers

Contributing to the improvement of suppliers’ skills and profitability and ensuring the consistent purchasing of raw materials

We pursue goals such as the improvement of the skills of raw material suppliers, the creation of jobs and the securing of steady income by, for example, lending equipment to Indian oil mills for free and providing technical guidance.

Asahi Kasei contributes to achievement of Sustainable Development Goals (SDGs).

Related SDGs

Background

Bemberg™ is made from the fuzz around the cotton seed, which is called cotton linters and is not normally used in cotton yarns. Cotton linters are supplied by the oil mills that make oil from cotton seeds. Being a natural material, however, there are problems in procuring cotton linters due to climate change and extreme price fluctuations. This is attributable to the unavoidable instability of the prices and quantities involved in the procurement of the raw materials that are an indispensable part of the production of Bemberg™ yarns.

As one of the world’s largest cotton producers, India has enormous potential to be a new supplier of cotton linters. But the number of oil mills equipped with cotton linter manufacturing facilities was limited in India and the country also lacked skills sufficient for the qualitative management of cotton linters.

The process of making cottonseed oil from cotton is described in Figure 2 below. In fact, however, nearly 95% of the oil mills in India extract oil without delinting the cotton seeds as shown in Figure 1 below. This only extracts the oil and its residues from the cotton seeds. As a consequence, Indian cottonseed contained many impurities and was of poor quality. Valuable by-products such as cotton linters and hulls, which could be obtained if delinting facilities were available, were not utilized.

We started pursuing solutions to these problems, the need to improve the profitability of the local oil mills, and our need for consistent procurement of raw materials.

Our activities and track record

Asahi Kasei lends, free-of-charge, the equipment and analytic devices necessary for the production of cotton linters to multiple oil mills in India, and dispatches staff to India regularly to provide technical guidance. This has led to the qualitative improvement of cotton linters, a raw material for Bemberg™, and has mitigated procurement concerns.

The quantity of Asahi Kasei’s purchase of cotton linters from India increased nearly three-fold from 2010, when the lending of equipment began, to 2019. We contribute to the increased profitability of oil mills.

Results for Bemberg™

Cooperation with raw material suppliers has enabled Asahi Kasei to consistently procure high quality cotton linters. This been a significant result that has stabilized the Bemberg™ business.

Contribution to society

Asahi Kasei’s free lending of equipment and technical assistance have enabled oil mills in India to produce high-purity cottonseed oil and improve their profitability and technological capabilities. Moreover, the oil mills have successfully developed new sources of income such as the sale of cotton linters, a by-product of cottonseed oil. Asahi Kasei will continue sending its technical experts to India to continue its efforts to ensure consistency in product quality. The commitment will continue to deepen as we intensify our pursuit of traceability which is becoming increasingly necessary in the global fashion industry.