Lead Acid Battery Separator

LAB Separator for  OVERVIEW

OVERVIEW

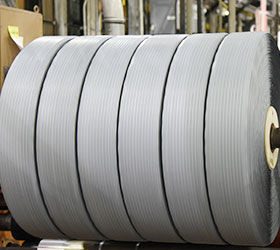

The importance of lead-acid batteries cannot be understated. They are used in many different applications, including in automobiles and forklifts. Generally, ultra high molecular weight polyethylene (UHMWPE) in a molecular weight range from 3 to 5 million g/mol is generally used as a raw material for the battery separators that are important components of lead-acid batteries.

It is necessary for the UHMWPE to be high quality to ensure long-term safety in operations in all kinds of conditions. SUNFINE™ boasts optimal grade designs and high quality that enables customers to provide high product quality.

Lead Acid Battery SeparatorEXAMPLE

Lead Acid Battery SeparatorGRADES

| Physical properties | Test method | UH910 | UH950 | |

|---|---|---|---|---|

| Average molecular weight (Mv) | 106g/mol | Asahi Kasei method | 3 | 4 |

| Bulk density | g/cm3 | Asahi Kasei method | 0.5 | 0.5 |

| Density | g/cm3 | ISO 1183-2 | 0.93 | 0.93 |

| Average particle size | μm | JIS K0069 | 100 | 110 |

| Melting point | ℃ | JIS K 7121 | 136 | 137 |

SUNFINEAPPLICATIONS

-

Lithium-ion Battery Separator

The high quality, optimized grades of SUNFINE™ improve the functions of lithium-ion battery (LiB) separators and achieve their stable production.

-

Lead Acid Battery Separator

Asahi Kasei proposes UHMWPE with low contaminants and stable physical properties to help batteries achieve a high level of safety.

-

High-strength Fiber

Developed from Asahi Kasei's experience supplying industry-leading companies, it offers a distinguished high molecular weight grade that helps achieve the functional enhancement of fibers.

-

Molding

Asahi Kasei offers several grades suited for molding applications. They contain a low level of foreign matter and have high whiteness. Some grades meet standards for food applications.