Bringing Innovation to Thick-Film Formation

The CX Series is a DFR that enables both high resolution and thick-film formation.

Details of the CX Series

Features: Achieving Both High Resolution and Thick-Film Formation

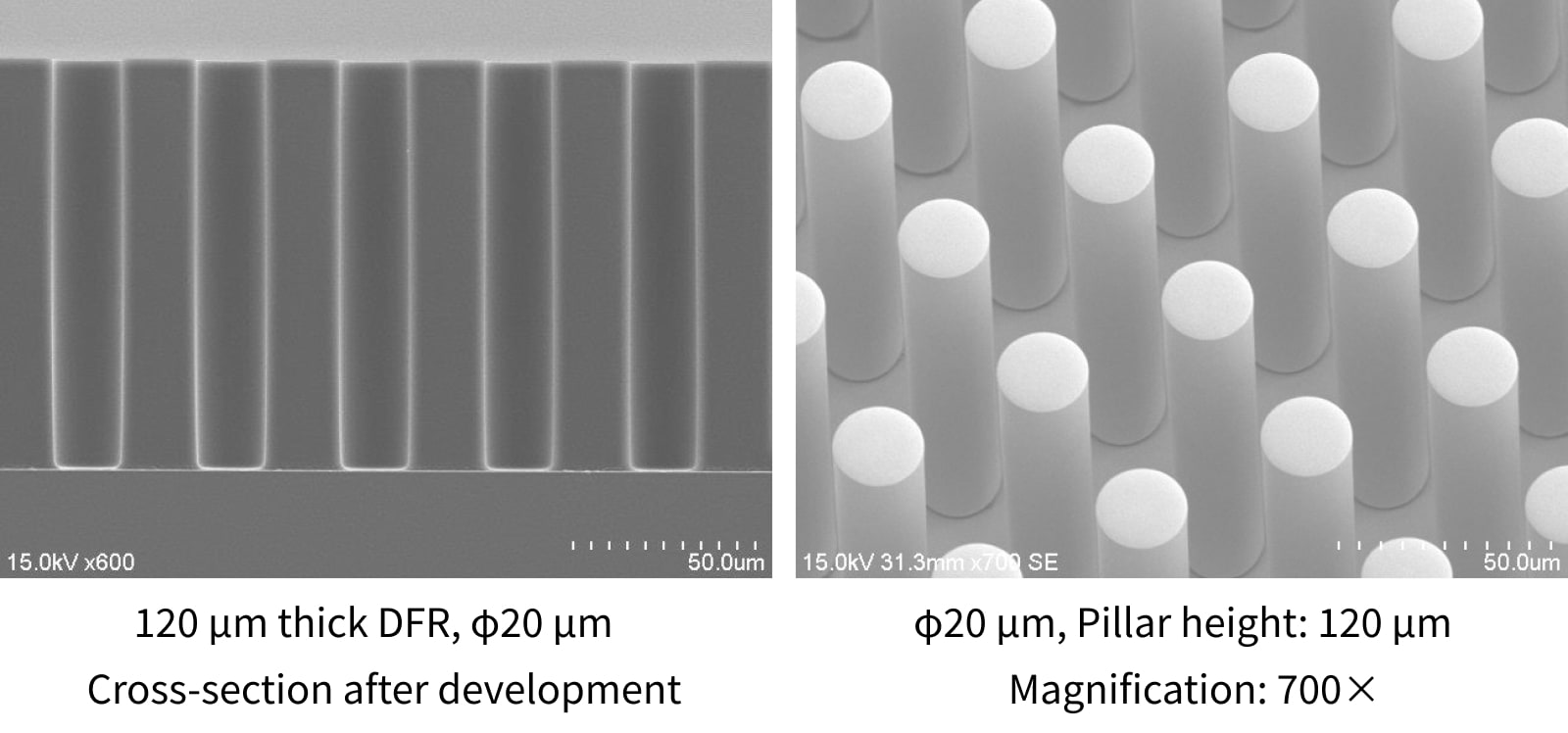

This dry film resist achieves a high aspect ratio (resist thickness/opening diameter) and good plating solution resistance, enabling film thicknesses of 200 µm or more. It supports high-aspect-ratio plating processes required for Cu pillar and Cu bump formation in Package on Package structures.

High Resolution and High Aspect Ratio: The CX Series achieves both high-resolution formation of fine structures and thick-film formation. It enables Cu pillar creation and contributes to three-dimensional circuit formation, supporting 3D integration methods such as Fan-out.

Efficiency in Thick-Film Formation: Capable of forming thick films of 200 µm or more in a single lamination step, eliminating multiple resist coating processes required with liquid resists. Simplifying the manufacturing process can enhance productivity and reduce process costs.

Good Chemical Resistance: Good chemical resistance prevents resist damage and enhances manufacturing stability.

Applications

The CX Series provides high reliability in the manufacturing of advanced devices such as Cu pillars and fan-out structures.

Cu Pillar Formation: For Cu pillar formation in high-performance electronic devices, the CX Series realizes precise and three-dimensional structures. It enables high-density, three-dimensional electrical connections in 3D structures such as Package on Package.

Resist Pattern

This is an electron microscope image showing the high-precision pattern formation of the CX Series.

Evaluation Cooperation: ORC MANUFACTURING CO., LTD. (Exposure) / JCU CORPORATION (Observation after plating)

For Inquiries or Sample Requests

For Prototype or Sample Requests, you can contact us via this link.Please consider SUNFORT™ "CX Series" for customers requiring high productivity and thick-film formation.