Polyolefin shrink film with multiple functionalities, No PVC added.

SUNTEC S FILM™ is a polyolefin-based shrink film for food packaging with over 40-year track record in Japan. As the industry reduce the use of PVC, our film offers an effective alternative, basically compatible with existing PVC packaging machines. Its multi-layer structure enhances packaging appearance and resillience during transportation.

Key Features

1. Manufactured with Polyolefin Resin

SUNTEC S FILM™ is produced with polyolefin resin, excluding PVC and PA additives.

2. Resistance to Transportation and Display Damage

By shrinking the film with heat, its strength and resilience improve, preventing tears and wrinkles during production, transportation, and display.

3. Better Packaging Appearance

Transparency, anti-fogging, and high resilience may help enhance the appearance of your products.

Detailed Features

■ Manufactured with Polyolefin Resin

・Reduced Packaging weight and waste : Lower density compared to PVC film.

・No hydrogen chloride gas when burned.

■ Resistance to Transportation and Display Damage

・Improved Strength and Resilience: By shrinking the film with heat, its strength and resilience improve, maintaining a tight package during transportation, storage, and display.

・Reduced Peeling: By sealing the film with heat on the tray‘s bottom, moisture-related peeling reduces.

・Low-Temperature Durability: Maintains flexibility and strength at low temperatures, preventing tears during frozen food transportation.

■ Better Packaging Appearance

The high transparency and anti-fogging properties of SUNTEC S FILM™ can help improve the beauty and attractiveness of your packaging.

Japanese Success Cases

Suitable for a wide range of applications, from frozen and refrigerated to room temperature. Examples include fresh foods, bento-box, prepared foods, and processed foods.

Achievements:

About 200 packaging centers, mainly major Japanese supermarkets

About 70 mushroom manufacturers, including the largest companies

About 130 seafood and aquatic product companies

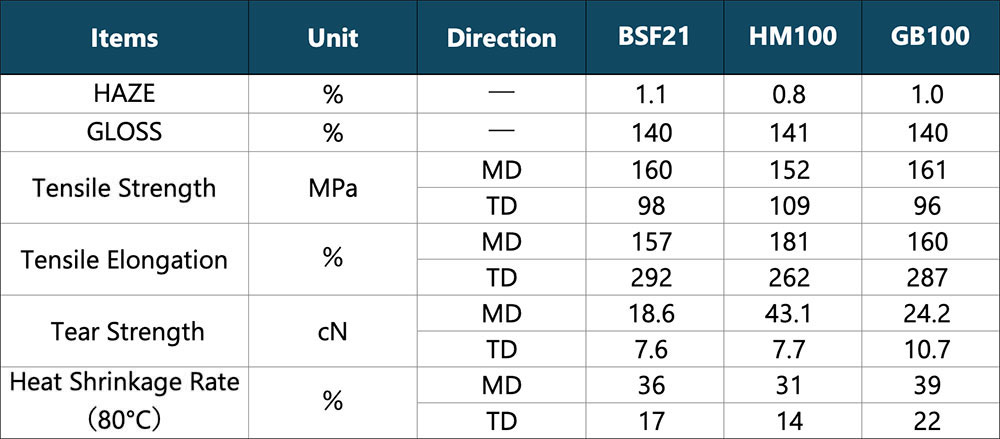

Specifications

・Measured values for reference only, not guaranteed product specifications

Related Products

Explore our "SUNNOVA™" film compatible with MAP packaging. For more information, click [here].