Environmentally friendly CO₂ technology

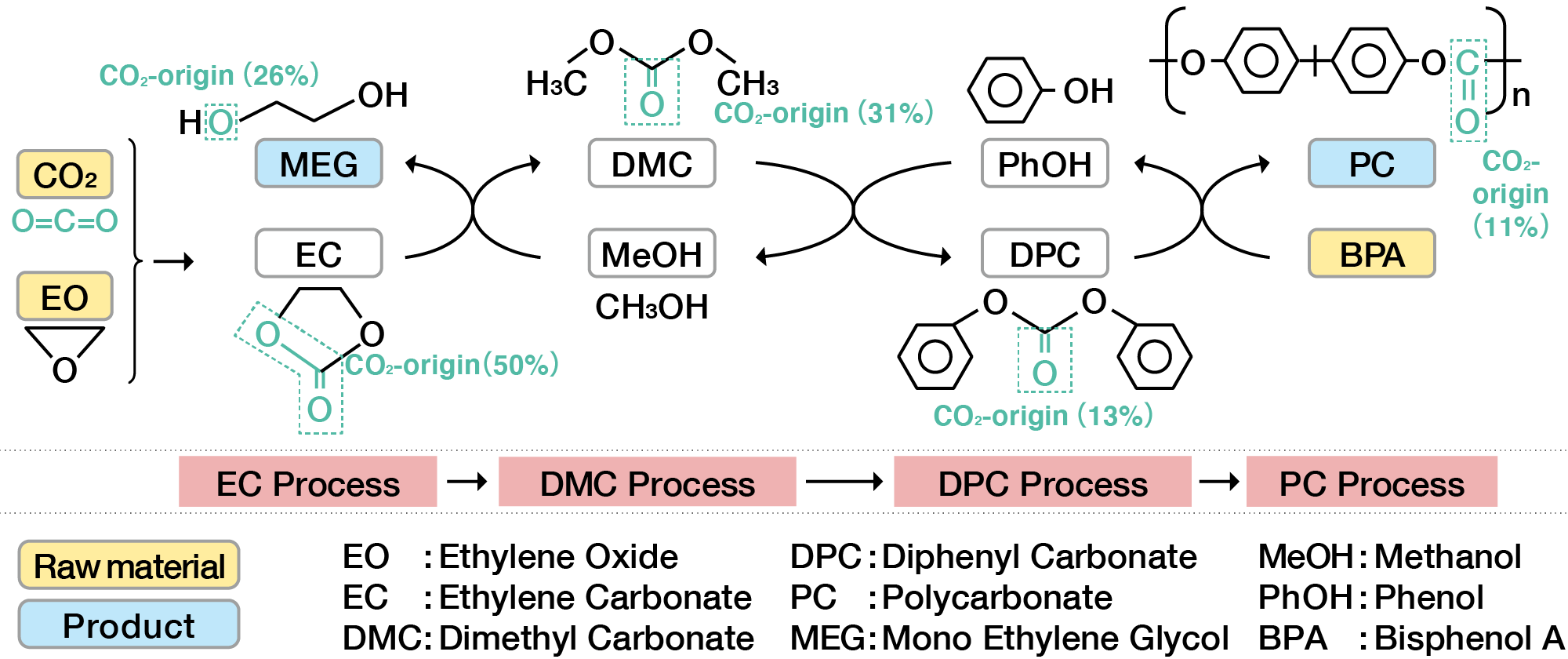

Polycarbonate(PC)production technology

Polycarbonate is used for many purposes as an excellent engineering plastic.

Major application of polycarbonate

Asahi Kasei is the first company in the world to commercialize polycarbonate production using CO₂ and ethylene oxide as raw materials, and has licensed the technology to PC manufacturers all over the world.

This is very environmentally friendly technology that consumes CO₂ as a raw material.

Asahi Kasei's

polycarbonate production process

In addition, this production method uses neither highly poisonous phosgene gas, nor methylene chloride, which is concerned about carcinogenicity.

This is an epoch-making process that saves resources and energy, reduces the amount of waste and wastewater requiring treatment and is cost competitive through stable physical properties and high quality.

【Reference】

- 「Development of A Novel Non-Phosgene Polycarbonate Production Process …Monomer Process Using By-Product CO₂」(Journal of Japan Society for Production Management 2005.1. Vol.11, No.2, P109-114)

- 「Received the Minister of Economy, Trade and Industry Award of the 2nd GSC Awards (2002) Asahi Kasei Corporation. Novel Non-phosgene Polycarbonate Production Process Using By-product CO2 as Starting Material」(JACI Textbook: Introduction to GSC ~Learning GSC from social practical cases that received GSC Awards Issued August 2016)

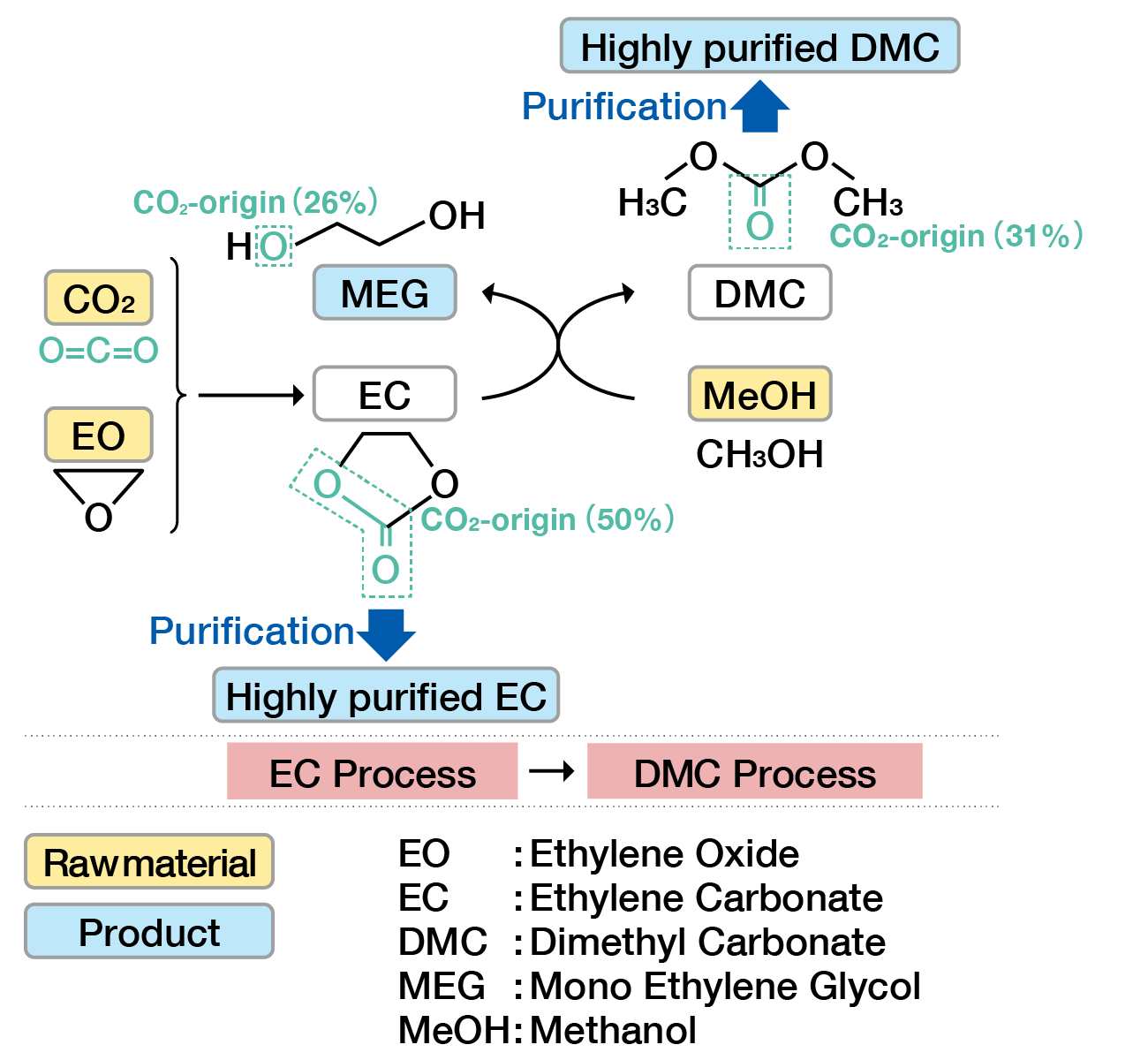

Highly purified carbonate (ethylene carbonate and dimethyl carbonate) production technology

Carbonate is a commodity organic chemical used as solvents, paints, pharmaceutical raw materials, gasoline additives, electrolyte components for lithium-ion battery(LIB), etc.

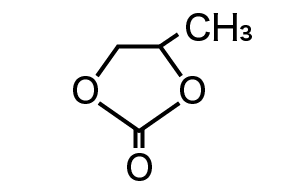

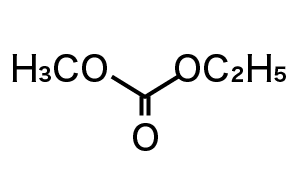

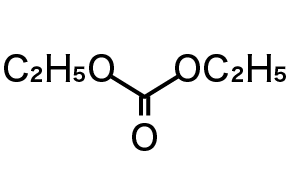

Ethylene carbonate (EC) is white solid, and dimethyl carbonate (DMC) is colorless liquid at normal temperature.

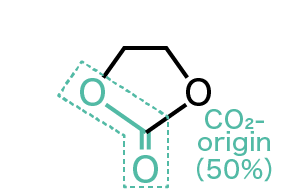

Ethylene carbonate (EC)

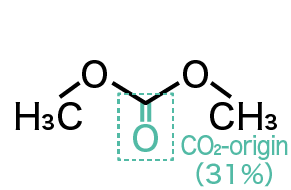

Dimethyl carbonate (DMC)

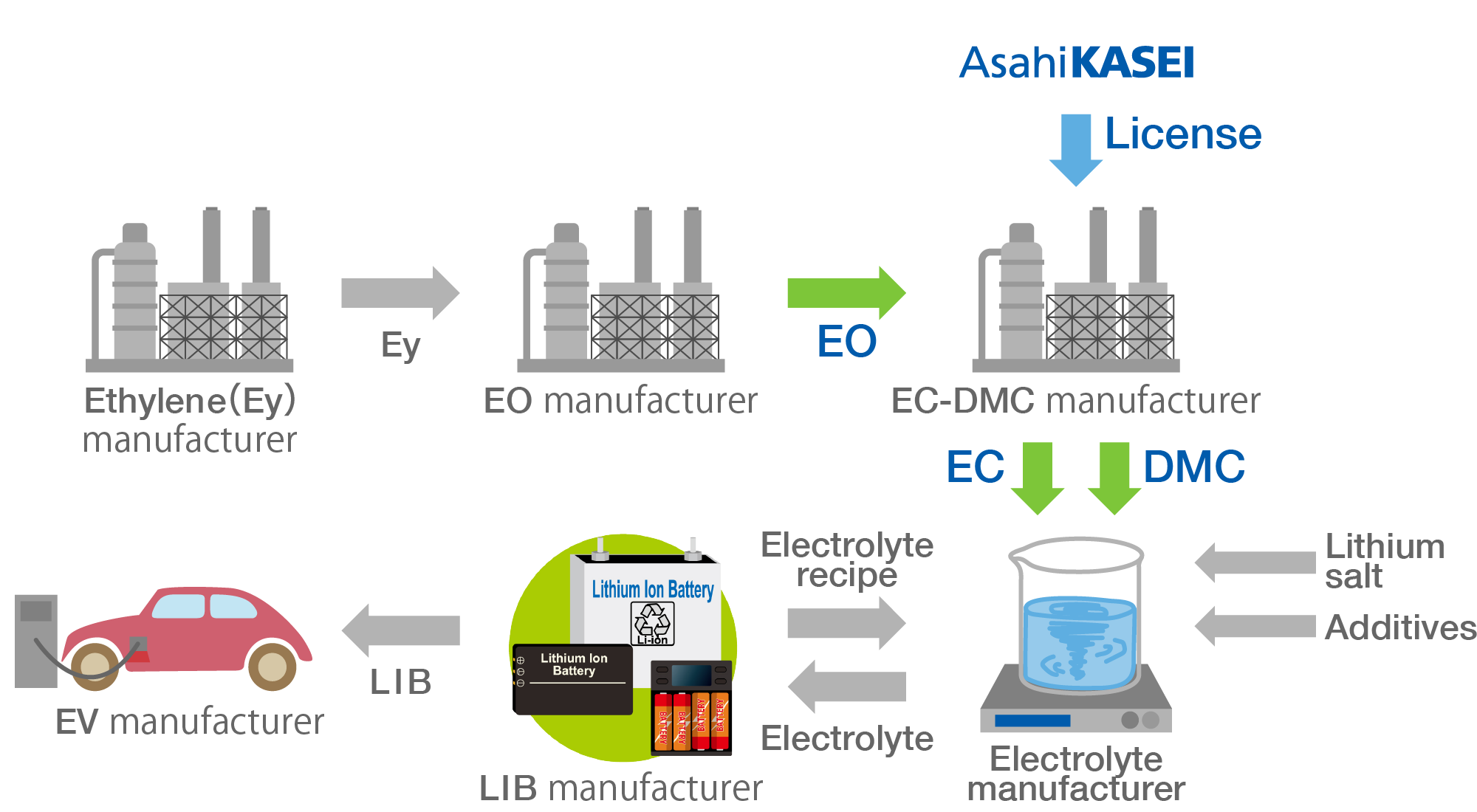

We have started licensing the production technology of highly purified EC and highly purified DMC by utilizing the PC production technology (2019).

50 wt% of EC and 31 wt% of DMC are originated from CO₂ respectively, so they are environmentally friendly processes that consume CO₂.

Asahi Kasei's

highly purified carbonate production process

Another feature of this process is to obtain high purity mono-ethylene glycol(MEG) as a by-product. Normally, in ethylene oxide (EO) -MEG plant, MEG is produced by hydration reaction of EO, and if our DMC process is installed in the midst of above EO-MEG process, it is advantageous that DMC can be obtained without affecting the original MEG production.

Major application of highly purified carbonate solvent

~electrolyte component for lithium-ion battery

Lithium-ion batteries are storage batteries installed in electric vehicles(EVs).

The electrolyte used in lithium-ion battery generally consists of a mixed solvent of the following five types of organic solvents, lithium salts and additives.

| Compound name | Cyclic carbonate | |

|---|---|---|

| Ethylene carbonate (EC) |

Propylene carbonate (PC) |

|

| Chemical structure |  |

|

| Compound name | Chain carbonate | ||

|---|---|---|---|

| Dimethyl carbonate (DMC) |

Ethyl methyl carbonate (EMC) |

Diethyl carbonate (DEC) |

|

| Chemical structure |  |

|

|

Highly purified EC and highly purified DMC produced by our technology have realized extreme high purity and can be applied for electrolyte component.

Highly purified EC and highly purified DMC produced by our technology are prepared into electrolyte by an electrolyte manufacturer, transported to a LIB manufacturer, and used as a LIB material.

We believe it also necessary to make components of LIB electrolyte used for EVs that don't emit CO₂ and are environmentally friendly, using environmentally friendly technology.

In fact, we have received many inquiries to our highly purified carbonate production process technology from many manufacturers in Europe and other countries with high environmental awareness, and are proceeding with licensing activities around the world.

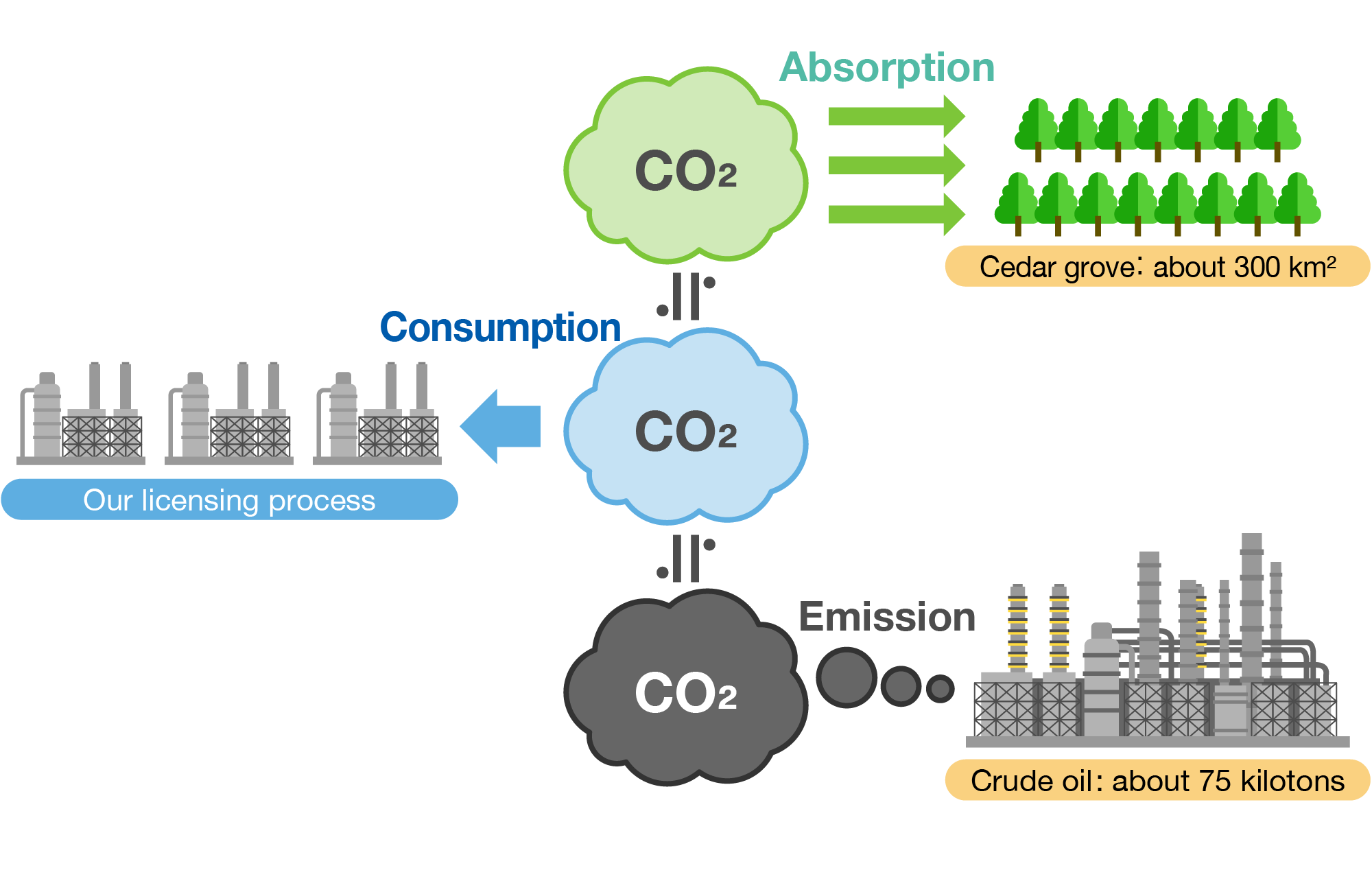

Contribution records through CO₂ technology

We have licensed the technology around the world since the year 2000.

Consumption amount of CO₂ as a raw material

The total amount of CO₂ consumed for 1 year as a raw material by our technology is equivalent to the amount of CO₂ emitted by the combustion of about 75 kilotons of crude oil, and is equivalent to the amount of CO₂ absorbed by cedar grove of about 300km² for 1 year.

Awards

Representative award results up to 2014 are shown. We have received high praise from all sides and have won many other awards.

| Award name | Award date | Award group |

|---|---|---|

| 2nd Green Sustainable Chemistry Award | 2003.3.14 | GSC Network |

| ICIS Innovation Awards 2007 | 2007.12.14 | ICIS Chemical Business |

| 2014 Heroes of Chemistry Award | 2014.8.10 | American Chemical Society |

Accelerating low-carbon society

~ Toward carbon neutrality

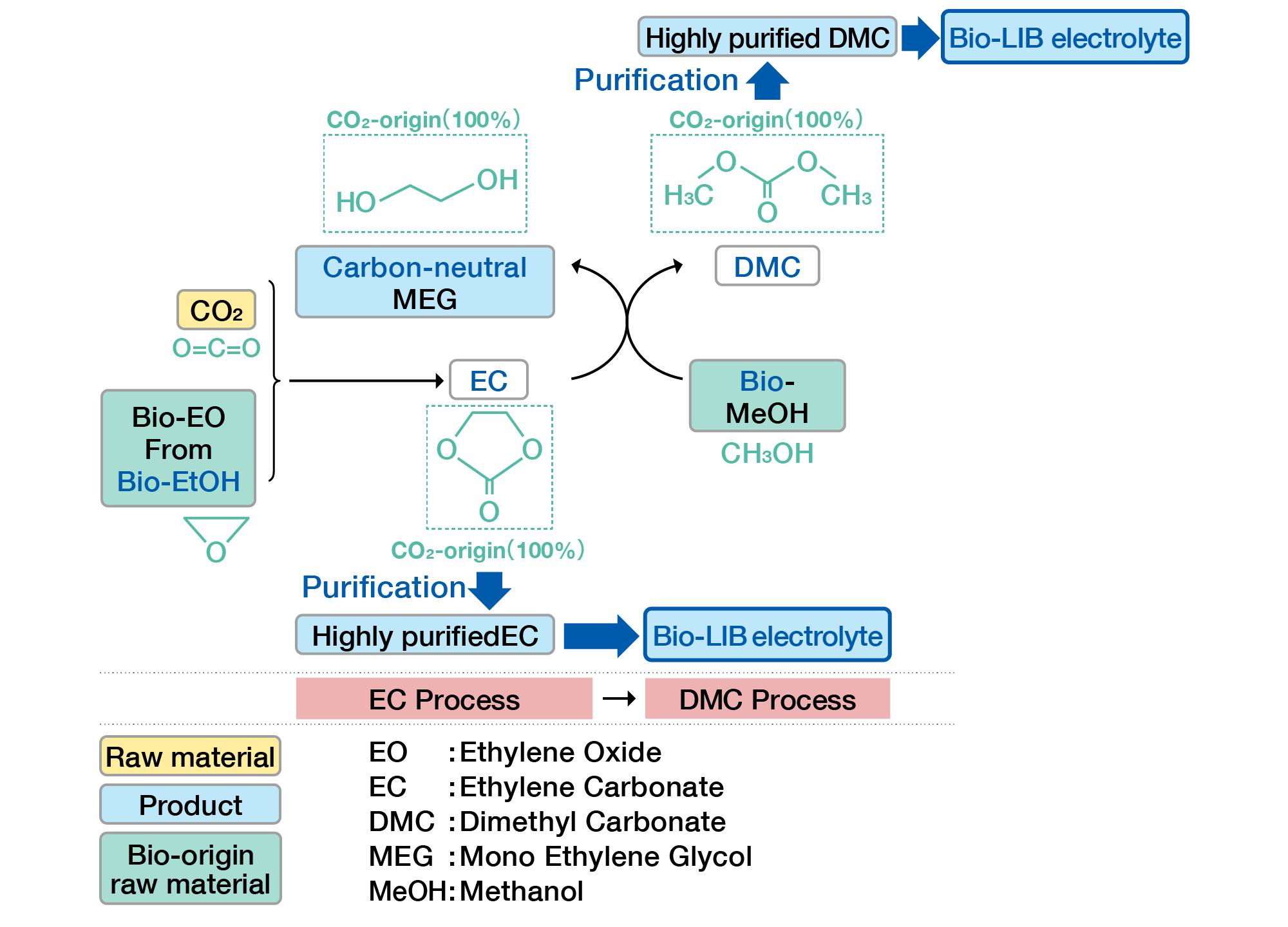

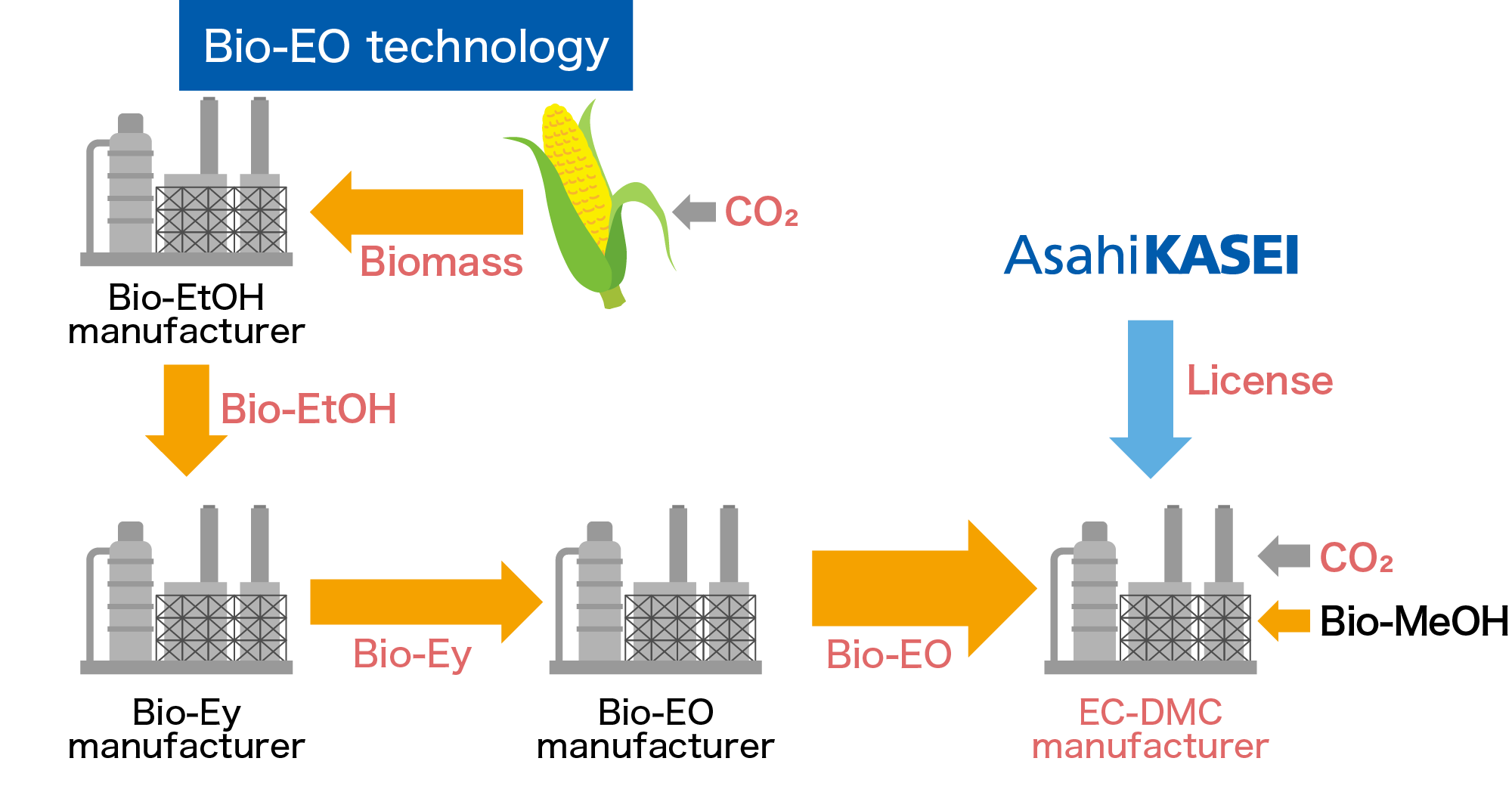

Utilization of bio-ethylene oxide (Bio-EO) technology

Ethylene oxide is usually made from ethylene, which is made from petroleum, natural gas etc.

In collaboration with a manufacturer that makes Bio-EO from bio-ethanol(Bio-EtOH) synthesized from biomass that absorbs CO₂, we now propose to the world more environmentally friendly process with which less amount of CO₂ emission is realized.

Realization of Bio-LIB electrolyte using biomass as raw materials

In addition to Bio-EO, we aim to realize a 100% Bio-Origin LIB electrolyte by using biomass-Origin methanol (Bio-MeOH) and renewable energy.

If you are interested in this process, please contact us. Would you like to realize it together?

Biomass-derived

highly purified carbonate production process