BEMCOT™ is a line of wipes for cleanrooms,made from Bemliese™,

the world’s only cupro continuous-filament nonwoven fabric

Origins

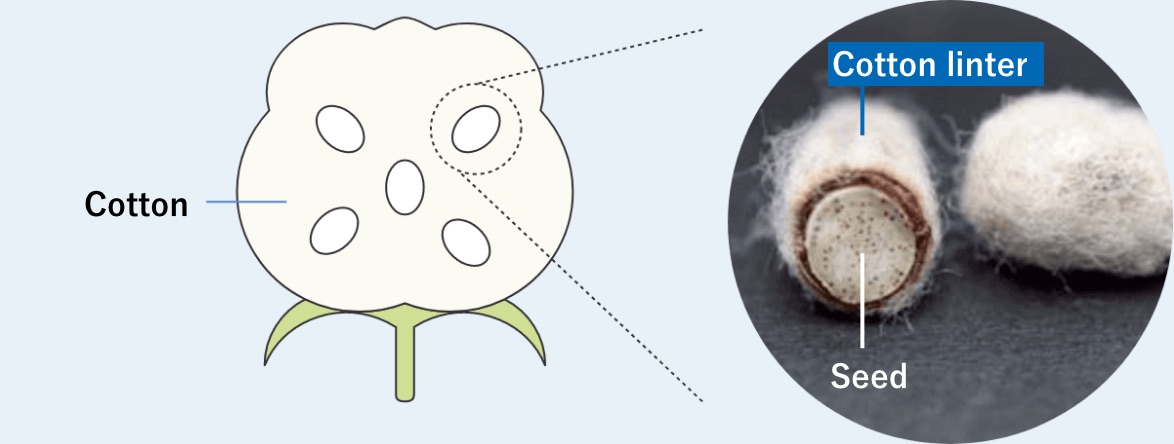

BEMCOT™ cleanroom wipes are produced from Bemliese,the 100% pure “cupro” cellulosic nonwoven derived from cotton linter-the fine,downlike fiber that naturally protects and cushions the seed of the cotton plant.

Cotton linter from around the world is transformed to pure cellulosic nonwoven sheets in an integrated process unique to the Bemliese plant of Asahi Kasei.

An ISO 9001 certified production facility located at Nobeoka City in Japan.

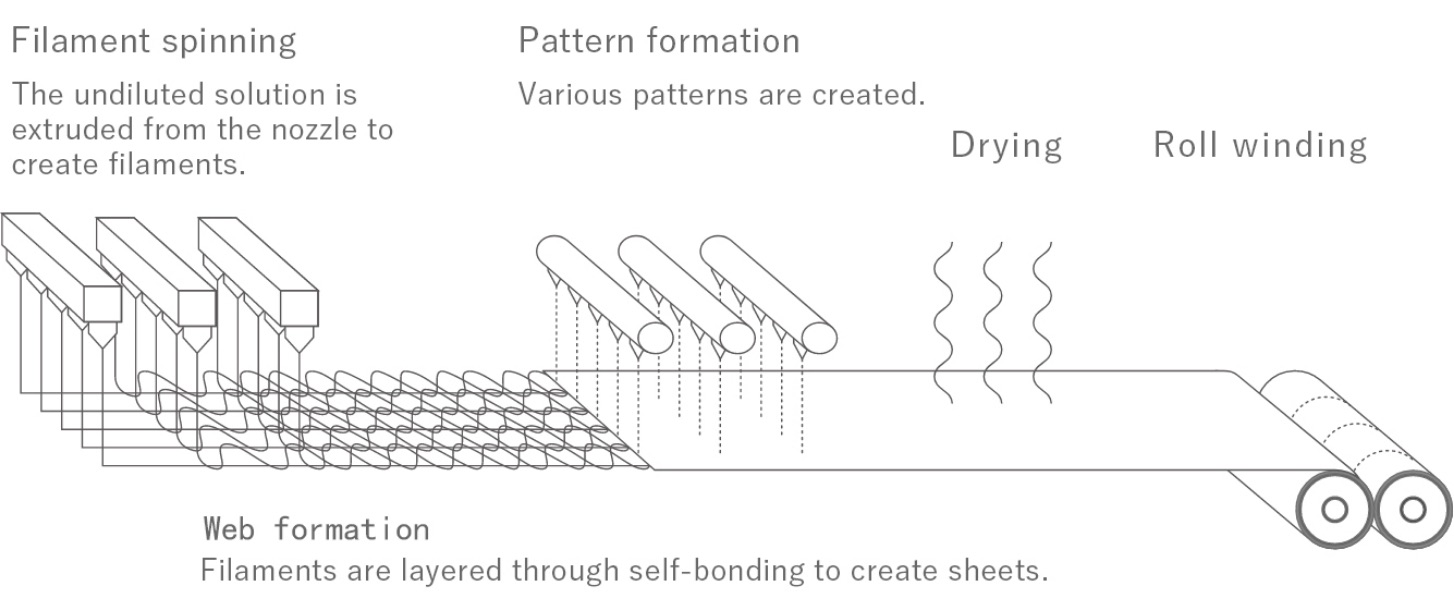

Production Process

Creating products with our proprietary technology

At the Asahi Kasei plant, refined cotton linter becomes the worldʼs only continuous-filament nonwoven sheets.Our proprietary technology enables a production process that uses 100% cellulosic filaments and their self-bonding capabilities.

- Linter refining

- After the cotton linter is cleaned, impurities are eliminated through repeated steaming and filtration to create refined linter.

- Linter dissolution

- Highly purified linter dissolved in a solution (undiluted solution)

Filament spinning to roll winding