Bemliese™ is made only in Japan, the result of naturally sourced materials formed into an outstanding product through superior processes and technologies that directly address environmental preservation.

The pristine setting of Nobeoka, Miyazaki Prefecture, the home of the Bemliese™ plant. Asahi Kasei has been producing Bemliese™ here since 1974, while continuing to implement procedures and policies that ensure the integrity of this environment.

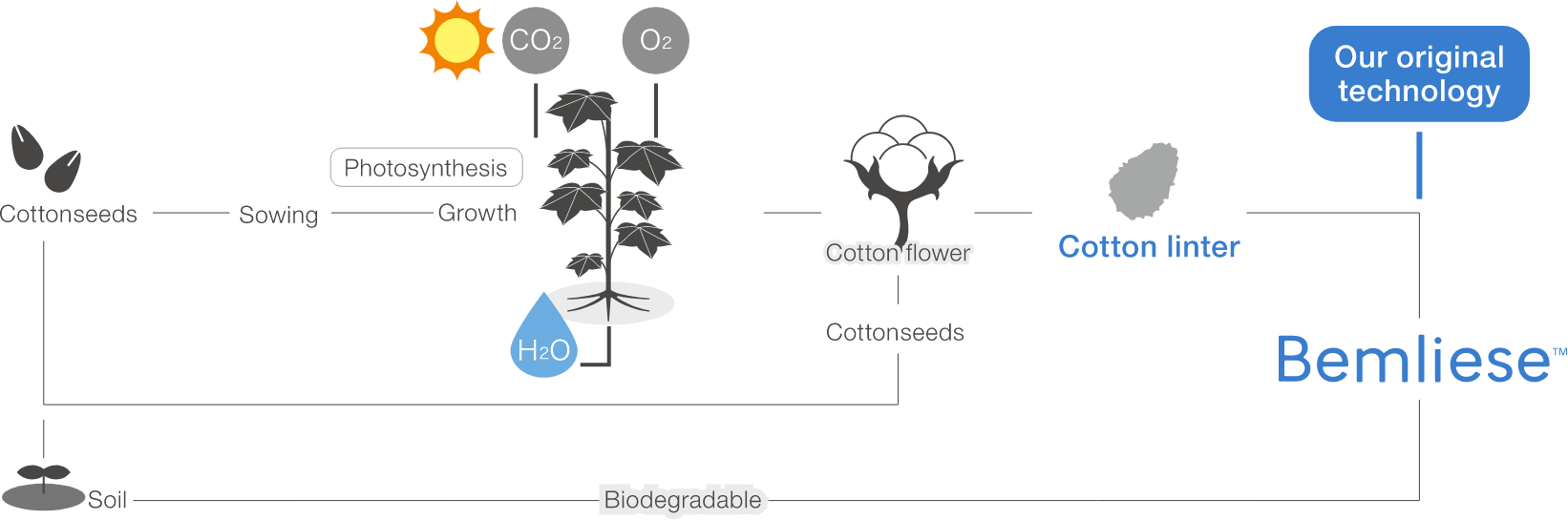

From Nature, Back to Nature.

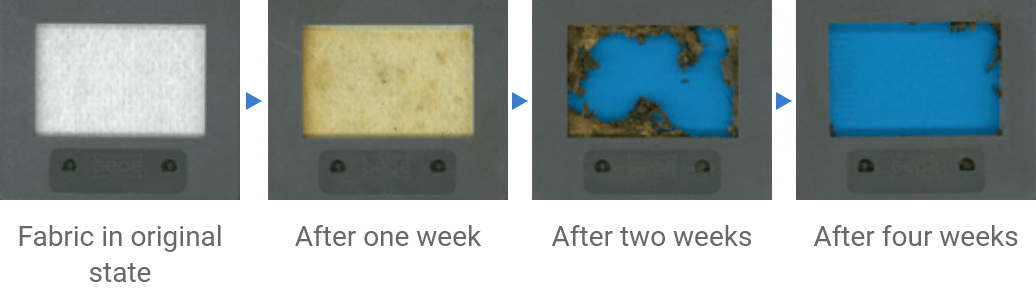

After use, returning to earth

Bemliese™ (110g/m2)

Because Bemliese™ comes from 100% cotton linter, it has excellent biodegradability that lends to natural decomposition. If returned to earth, Bemliese™ will be broken down by microorganisms.

Biodegradability test, by mixing nonwoven fabric with compost and incubation in a dark place at a temperature of 28℃. Water content checked regularly. Adjusted as needed. Compost regularly stirred, with visual verification of the state of decomposition of nonwoven fabric.

The cottonseed cycle

Bemliese™ Embodies Manufacturing Based on Environmental Impact

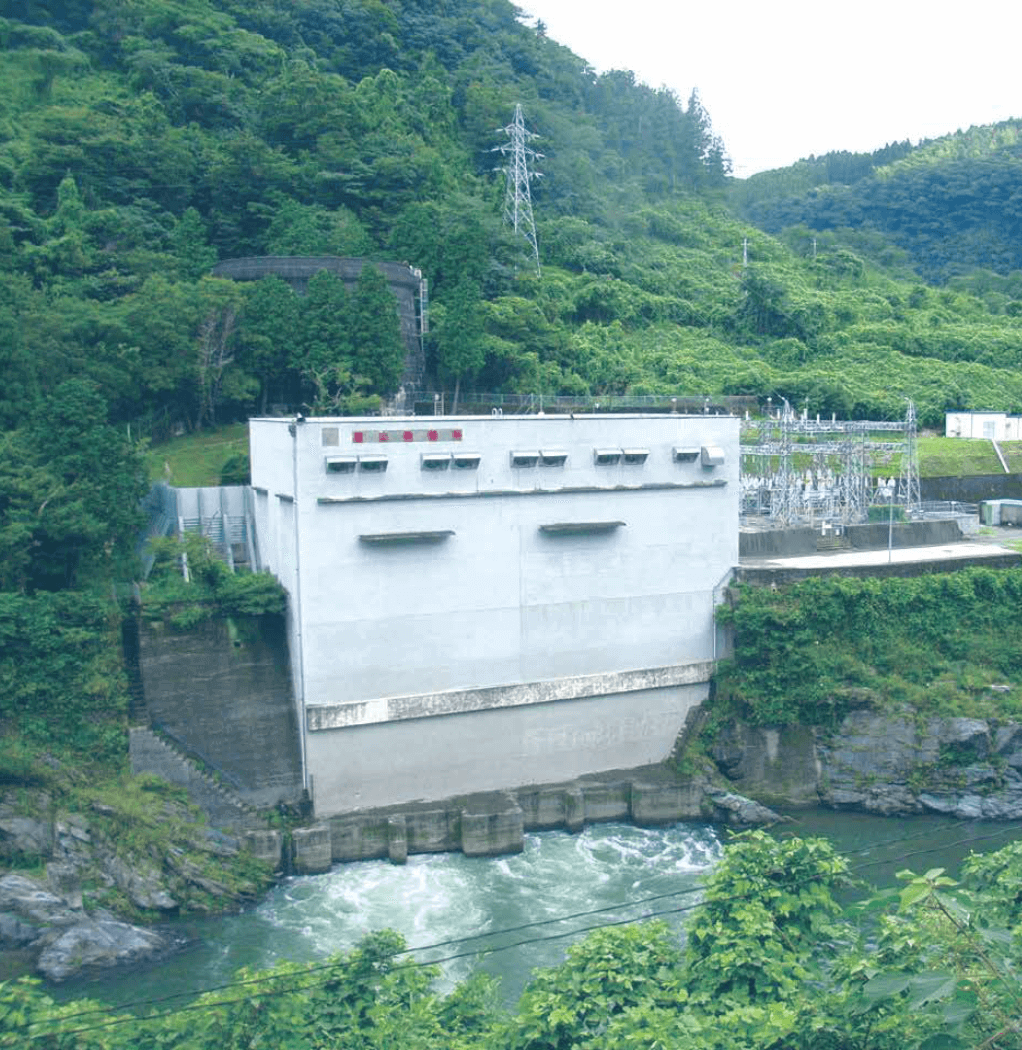

Number of Asahi Kasei's hydropower generation facilities: 9 (oldest in service since 1925)

Photo: Hoshiyama Hydropower Plant

In-house power generation infrastructure

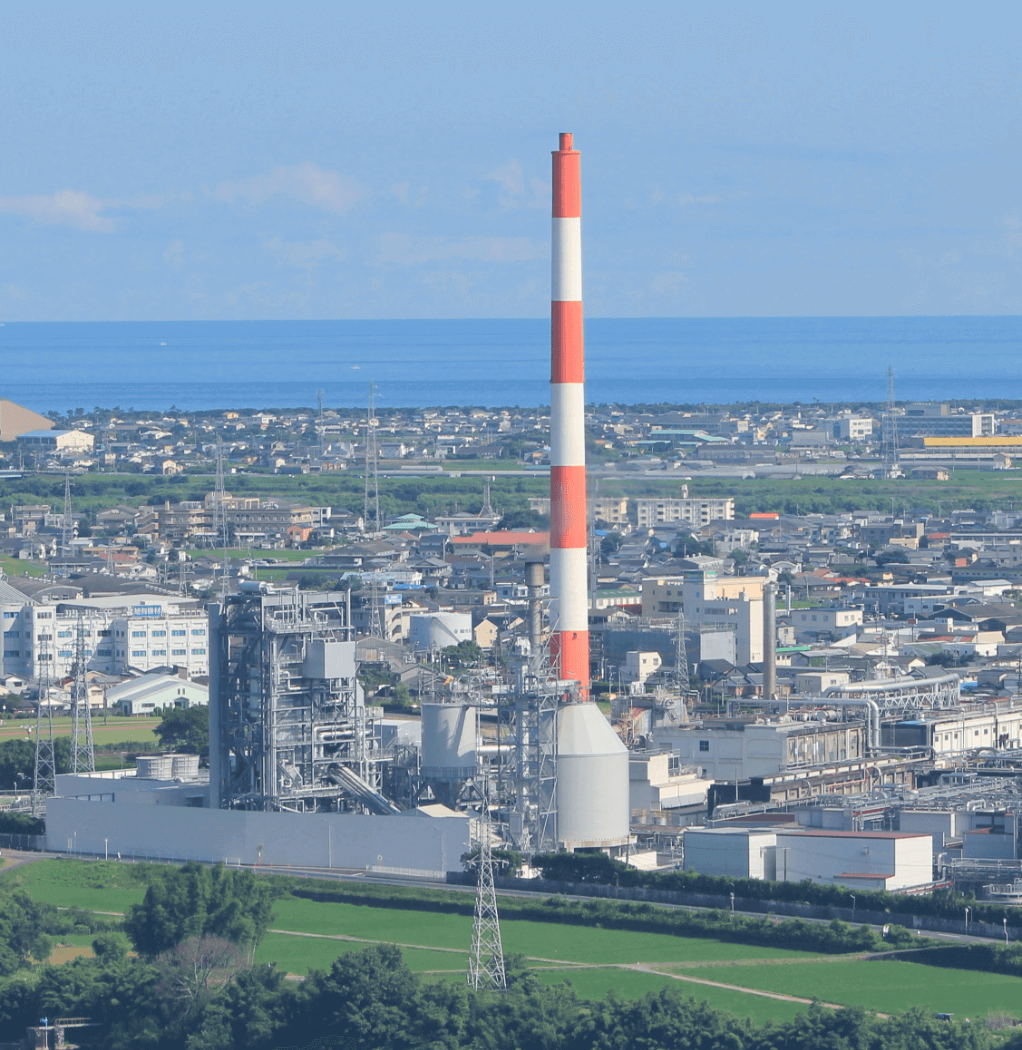

The Benliese factory in Nobeoka City, Miyazaki Prefecture uses Asahi Kasei's own power generation equipment. There are nine hydroelectric power plants and four thermal power plants, and we are self-sufficient in approximately 90% of the electricity used in the area. In order to increase the ratio of clean energy usage, we have been updating hydroelectric power plants, introducing biomass power generation, and reducing coal power generation. We will continue to consider ways to make energy cleaner in the future.

*2019 data for Asahi Kasei Nobeoka region renewable energy consumption rates (hydroelectric, approx. 27%; biomass, approx. 8%)

Number of Asahi Kasei's biomass power generation facilities: 2 (since 2012)

Photo: Okatomi Biomass Power Plant

We minimize waste.

By reducing and reusing waste itself, we try to eliminate the waste that is eventually disposed in landfills. Asahi Kasei thoroughly recycles waste generated from its factories, such as by reusing textile scraps resulting from the production process of Bemliese™ as biomass fuel for power generation.

Meeting Stringent Global Standards.

Asahi Kasei and Bemliese™ have undergone testing and certification in a number of international standards for material, manufacturing process and environmental impact. Moreover, our commitment is to continue adhering to our certifications and building further credentials for meeting sustainability goals.

Assessments and certifications

Standard 100 (Oeko-Tex®)

Standard 100 by Oeko-Tex® is a worldwide consistent and independent system for testing and certification of raw, semi-finished and finished textile products at all processing levels. It aims to level out global differences for assessment of possible harmful substances in textiles.

VEGAN (V-LAVEL)

V-Label is an internationally recognized and protected seal label of quality for vegetarian and products and services by the European Vegetarian Union (EVU).

Vegan (Vegan-Korea)

It is an internationally recognized label for vegan products and services of quality by KVCS (Korea Agency of Vegan Certification and Services), the first vegan agency in Korea.

ISO-14001

The IS0-14001 certification recognizes our corporate system and policies to continuously alleviate and/or prevent the environmental impact of our products, services and corporate activities.

ISO-9001

The ISO-9001 certification acknowledges our quality management system aimed at improving customer satisfaction with better products and services.

OK biodegradable MARINE,OK biodegradable WATER, OK biodegradable SOIL, OK compost INDUSTRIAL, OK compost HOME (TÜV Austria)

OK biodegradable MARINE

Certification that in marine conditions, the material meets specific biodegradability and disintegration requirements and does not have high levels of ecotoxicity to marine life.

OK biodegradable WATER

Certification that the material is biodegradable in the natural fresh water environment and thus contribute significantly to reducing waste in rivers, lakes or any natural fresh water.

OK biodegradable SOIL

Certification that the material is biodegradable in the soil for planting from fields and forests, without adverse environmental effects.

OK compost HOME

Certification that the material is biodegradable under home composting conditions based on a lower temperature of 28°C.

OK compost INDUSTRIAL

Certification that the material is biodegradable in an industrial composting plant, and does not have high levels of ecotoxicity for the environment.