V-MO developed exclusively

for marine motors

To support even safer and more secure

operations, we conducted monitoring and

verification at 200 sensors, 90 equipment on

13 vessels owned by MOL for five years.

V-MO is a marine motor monitoring service

optimized for vessel’s environment.

This video explains its main features.

V-MO strongly supports

safe operation and promotes digital transformation on vessels.

To support your safe operations.

V-MO allows easy and proper

monitoring with vibration detection.

Data is automatically collected and

analyzed, making it possible to identify

abnormal parts at an early stage.

Able to manage 24 hours from the shore

and the vessel.

Early detection of abnormal signs

reduces maintenance costs.

optimized for vessel’s environment

V-MO has a vibration diagnosis technology that is optimized for vessels.

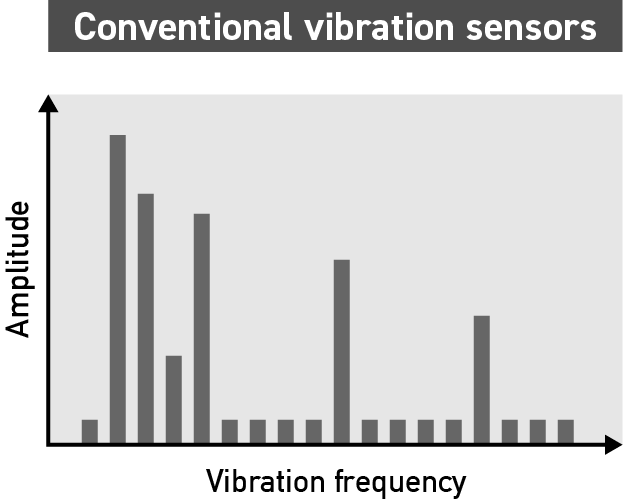

With conventional vibration sensors, it would be affected by noise and might miss vibrations originating from the motor. However, V-MO can catch vibrations from the motor by filtering the noise and realize early detection of abnormalities.

technology commonly used in onshore factories

Abnormalities that cannot be detected

by current / temperature measurement, can be detected earlier by vibration detection.

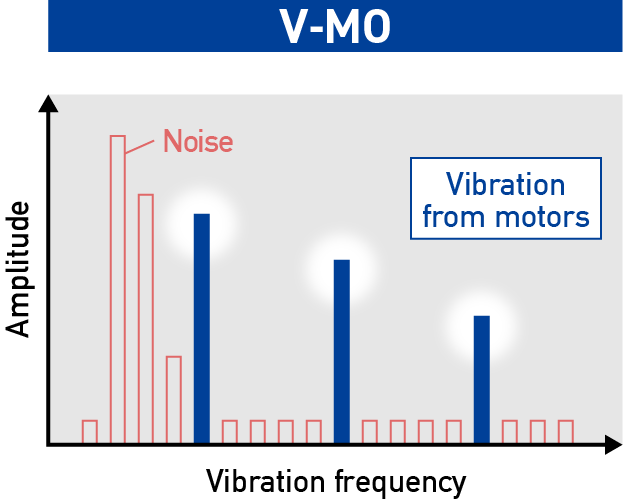

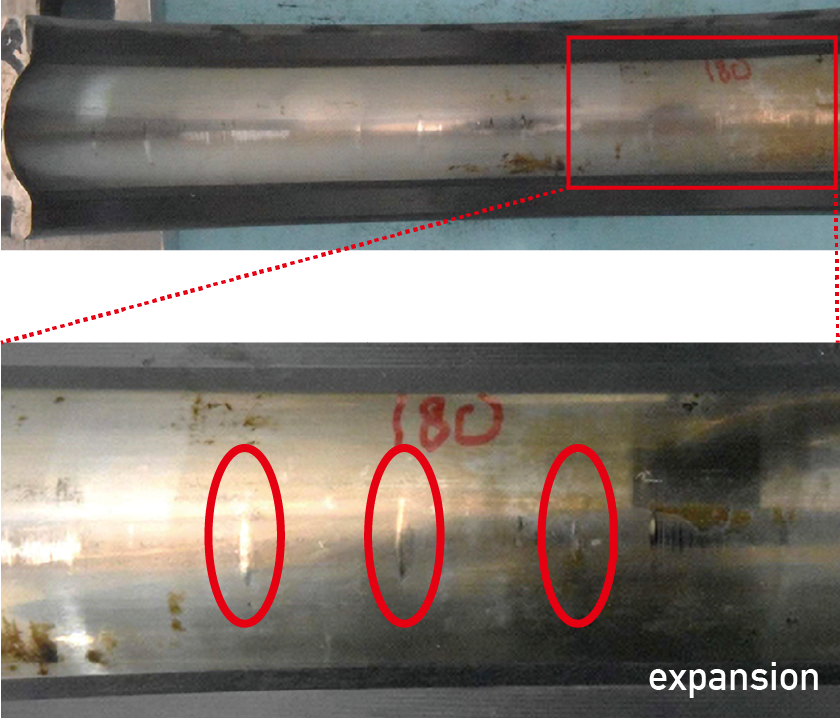

As a result of the open inspection, a gap of 0.06mm was found between the shaft and the bearing. Major damage was avoided by early response.

Auxiliary blower motor shaft and bearing during open inspection

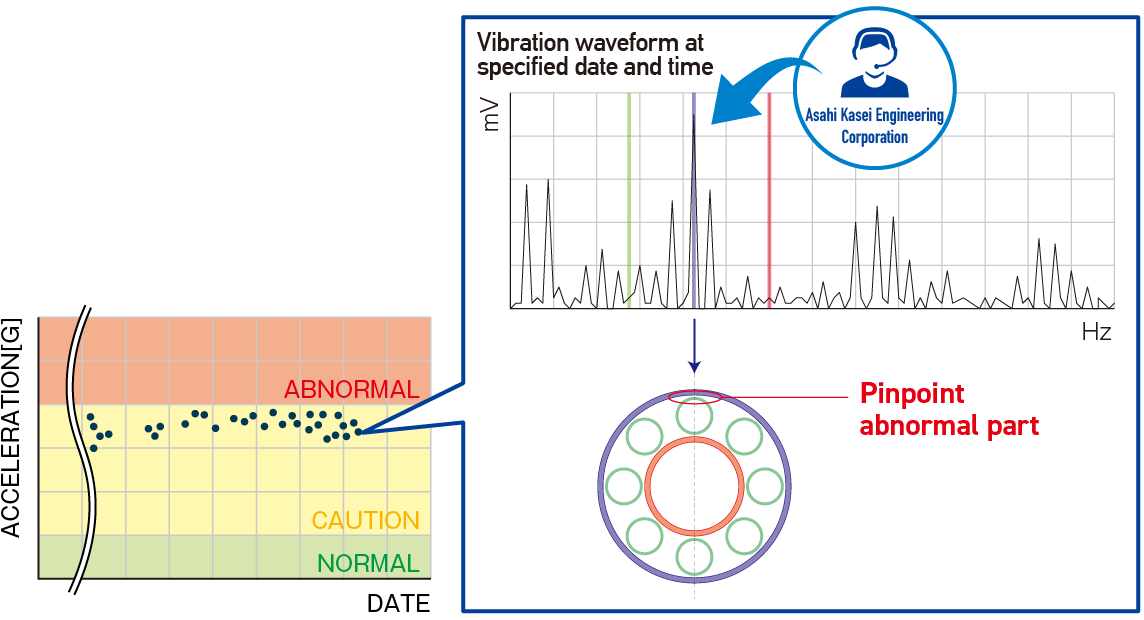

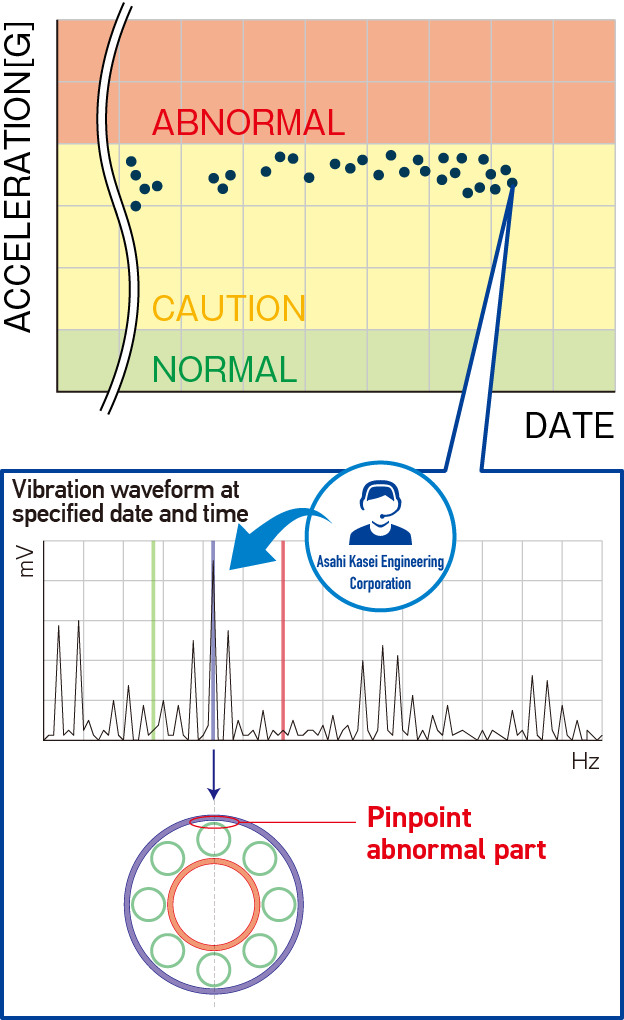

Abnormal parts can be identified by frequency analysis.

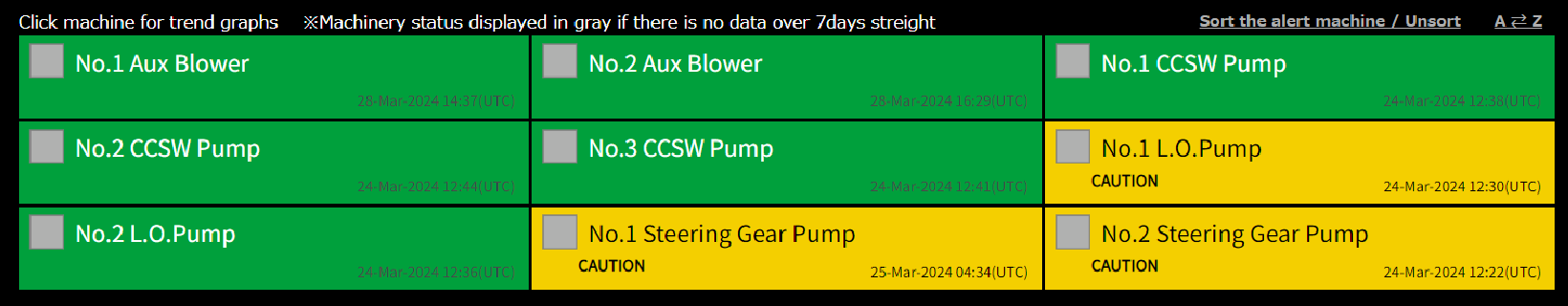

With our V-MO cloud application, even if you are not familiar with vibration diagnosis, you

can properly monitor equipment.

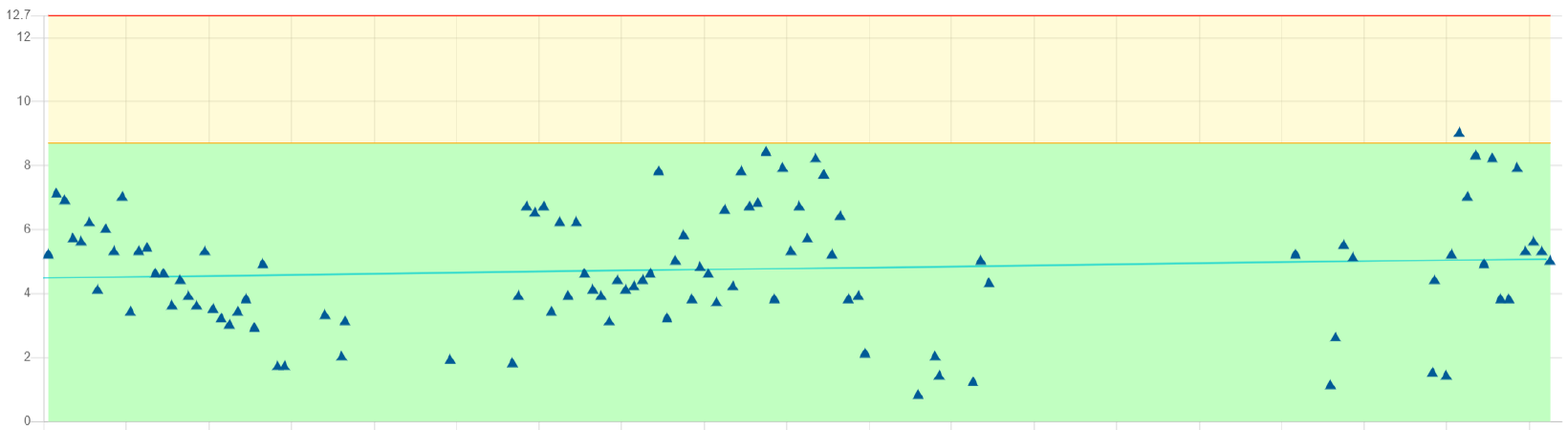

For example, if the equipment status is in the caution range in a Trend graph, you can use

the FFT function to identify where the bearing

abnormality is.

V-MO cloud application

Engine room motor

Considering the unique

vessels environment

The bearing abnormality “false brinelling” is caused by vibrations particular to vessels when the equipment is stopped. Unlike on land, in vessels environment where there is a lot of vibration, metal comes into contact with metal many times while the vessel is stopped and causes the wear. This is one of the typical damage patterns for bearings.

Inside the bearing

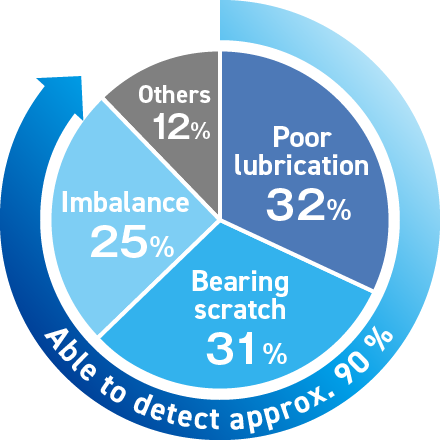

Vibration diagnosis can detect approx.

90% of abnormalities in rotating equipment.

Vibration, lubricating oil, electric current, and temperature are commonly used for rotating equipment in onshore factories. Among these, vibration diagnosis is known for its ability to detect various abnormalities at an early stage.

*Maintenance Status Survey Report FY2002 Japan Institute of Plant Maintenance

Detectable abnormalities by vibrations in rotating equipment

Supporting engineers’ five sense inspections

Equipment status can be accurately and objectively understood from the vessel and the shore.

Criteria which determining normal or abnormal are set by Asahi Kasei

Engineering's qualified vibration diagnostic specialists.

V-MO provides quantitative and objective information, allowing engineers to understand the

status of equipment by looking at

the screen.

V-MO cloud application TOP

V-MO cloud application Trend graph

Remote assistance with cloud application

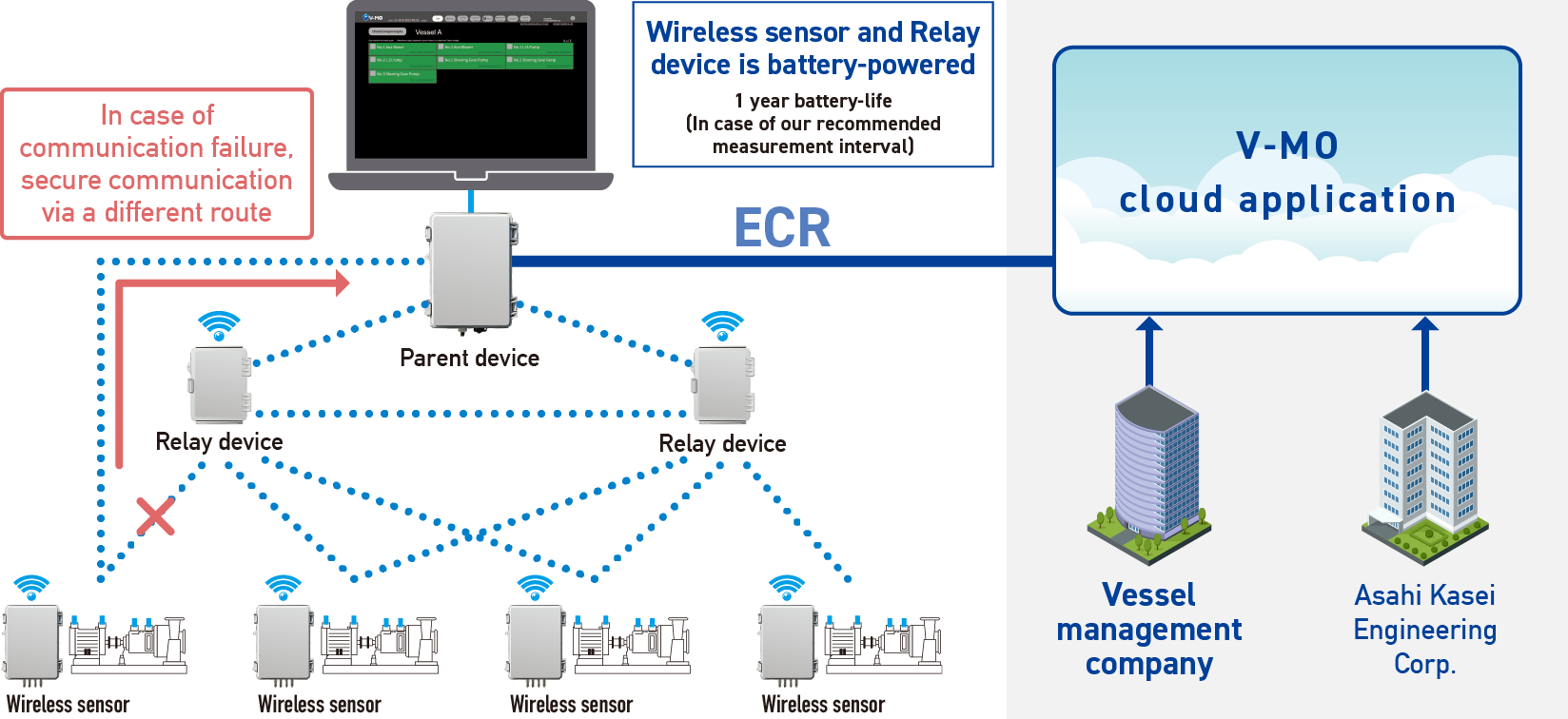

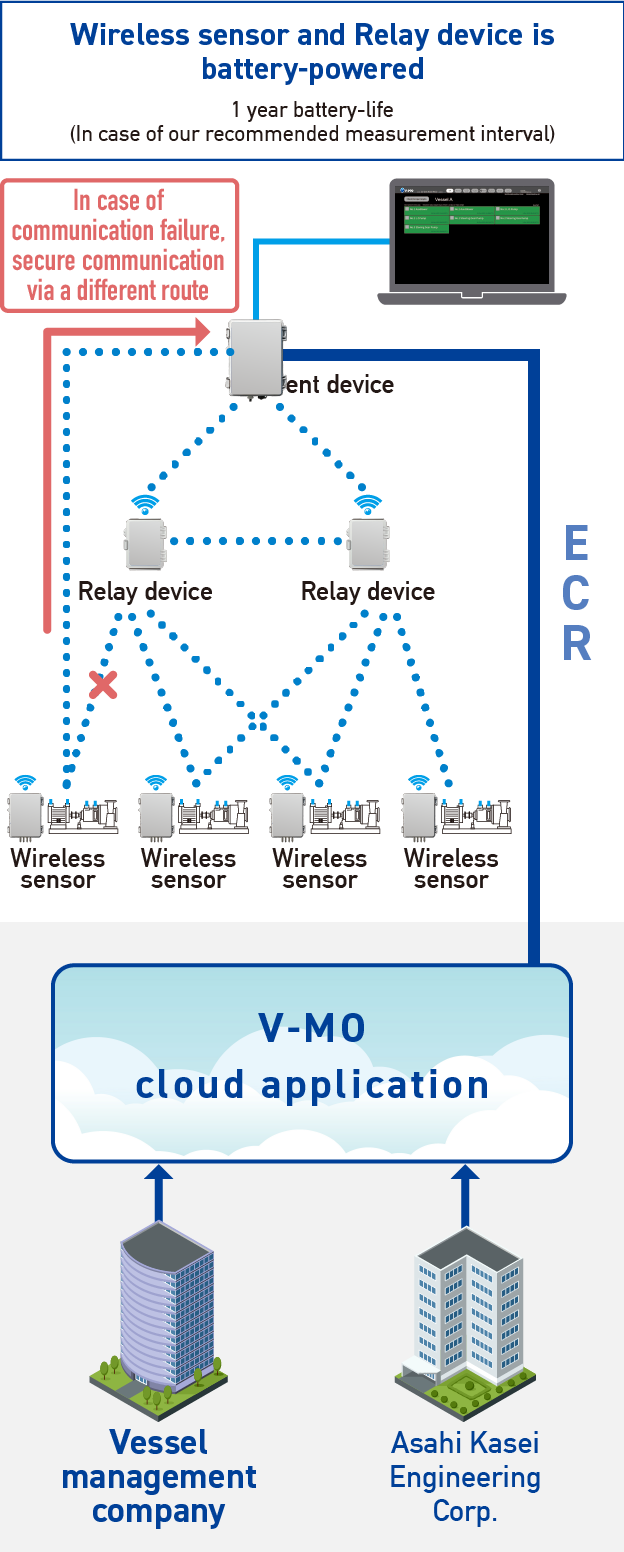

V-MO consists of IoT and cloud application

Parent device and V-MO dedicated PC are installed in the engine control room,

and Wireless sensor, Relay device, and Acceleration sensor are installed in the

engine room. Installation can be done by your engineers.

Data is automatically collected and transferred to the cloud, so the same data

can be monitored from the shore.

Wireless network formed by V-MO installation

Set up

Installation manual and online supports are provided.

Easily retrofitting and expanding for both newly built

vessels and vessels already in service.

Installation of Acceleration sensor and Wireless sensor

Installation of Acceleration sensor and Wireless sensor

Installation of Acceleration sensor and Wireless sensor

Operation

Since the data is measured automatically, the measurement is not affected by differences in crew experience.

Service overview

- Configuration

- A set of acceleration sensors, Parent device,Wireless sensors, Relay devices, Dedicated

PC, Installation equipment and Installation and operation manual.

●Installation can be done by your engineers.

*Upon special request, Asahi Kasei Engineering technician for installation are also available with a fee-charging. - Key service

- ■24 hours a day, 365 days a year*, confirmable monitoring system

*Data collection is once a day (Even if the satellite is interrupted, the onboard independent system enables on-board monitoring.)

■Diagnosis (Standard) ·Precise analysis (Option)

-

ClassNK “Innovation Endorsement Approach”

V-MO has obtained the third-party certification of innovations and initiatives (concepts and real services) “Innovation Endorsement for Products & Solutions” certification by Class NK.