TOP > PRODUCTS

Component with WGF™

Polarization filter for infrared cameras

WGF™ Camera Filter

When you get a WGF™ camera filter, you can attach it to your camera lens unit as usual and use it at the moment. It supports wideband imaging from CMOS to InGaAs.

Product Information

Reflective polarized lens

WGF™ Lens

Asahi Kasei has developed a reflective polarized lens, or WGF™ lens, on which wire grid film is 3D laminated. Pancake Lens is a crucial part of the optical system in VR.

Product Information

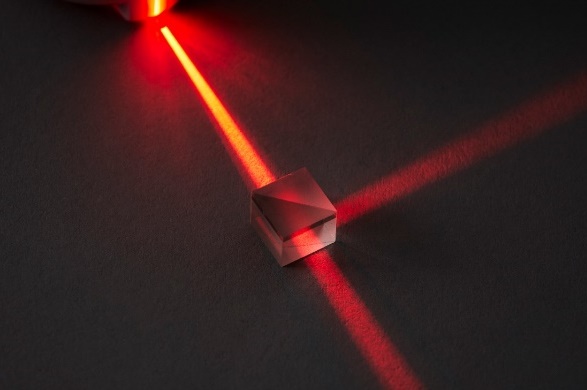

Polarized Beam Splitter

WGF™ PBS

When you choose WGF™ PBS, you can order various sizes such as 40 mm or 50 mm, and select glasses with a refractive index according to the equipment. It is already utilized in optical instruments such as substrate inspection equipment as well as AR Glass.

Product Information

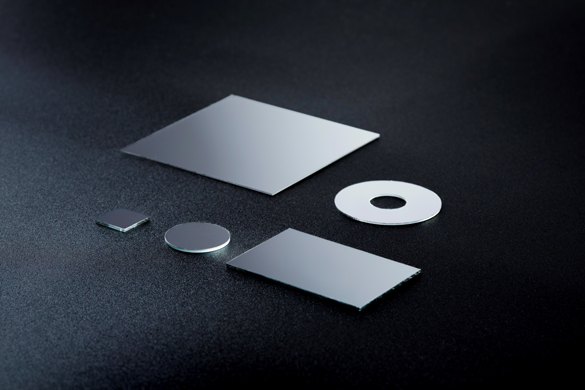

Wire Grid Polarizing Film

WGF™

Introducing the basic characteristics and features of WGF™.

Product Information