- Japanese

- English

DELPET™

Acrylic resin DELPET™Overview

Asahi Kasei acrylic resin DELPET™ is a superior acrylic resin molding material with excellent transparency, surface hardness and chemical resistance. Acrylic resin has the greatest transparency and weather resistance among all plastic resins. It is known as the ""queen of plastics"" because of how it keeps its unique, elegant luster over a long period.

In order to respond to the diverse needs of our customers, we have created a lineup with specialized grades including super heat-resistant, high jet black, high-fluidity, solvent-resistant and impact-resistant grades—in addition to standard grades—utilizing technologies such as suspension polymerization, continuous solution polymerization.

DELPET™ is used for a range of applications taking advantage of its features including auto parts, optical parts, industrial parts and miscellaneous goods, and has earned a high level of trust from customers. Asahi Kasei produces these grades from monomers to products using a consistent manufacturing system, with a commitment to ensuring thorough quality control.

Introduction of DELPET™ PB Grade

"This Resin is Too Black to Simply Call 'Black'"

DELPET™ PB Series of acrylic resins is ideal for exteriors, with an extensive range of grades that can maintain high jet black coloring over a long period and meet demands such as high fluidity and solvent resistance.

These resins offer the same weather resistance and surface hardness as general acrylics, removing the need for painting and leading to reduced environmental impact.

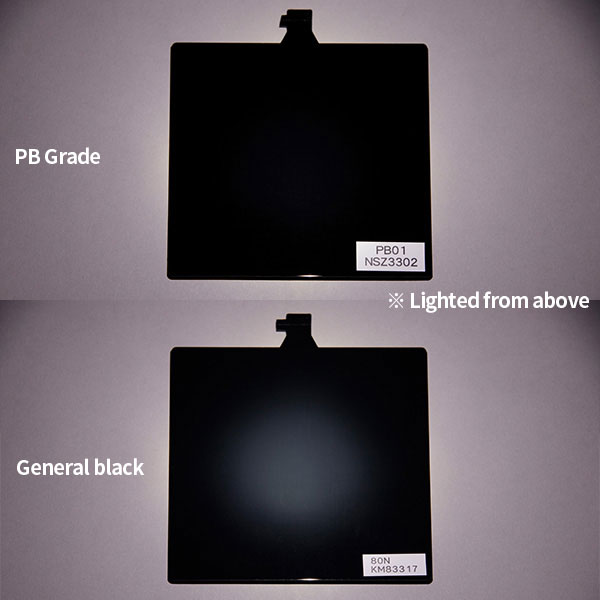

Feature 1: High jet black

PB Series acrylic resins have less external light reflection than standard black acrylic resins, offering excellent jet black coloring.

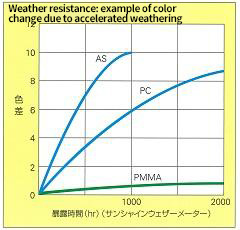

They also exhibit weather resistance comparable to that of standard black acrylic resins.

Feature 2: Coating-free

High surface hardness of acrylic resins allows them to be utilized without painting or coating, enabling use in place of ABS or polycarbonate resin coated parts. This enables cost reductions and helps to reduce environmental impact.

Feature 3: Extensive grade lineup

High-fluidity grades contribute to shortening molding cycles by lowering molding temperatures. Solvent-resistant grades cleared vehicle manufacturers' solvent resistance tests. This helps to achieve a good external appearance by suppressing stringing when joining with other resins by hot plate welding.

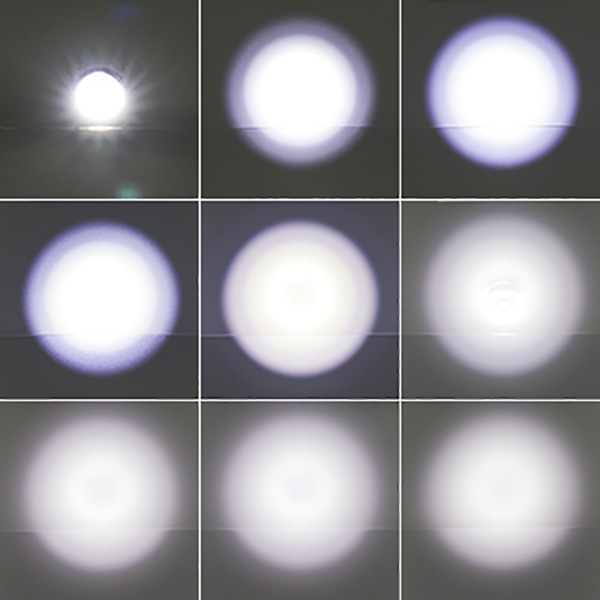

Introduction of DELPET™ Light Diffusion / Scattering Series

For More Expressive Lighting"

DELPET™ Light Diffusion / Scattering Series acrylics improve exterior appearance and design through abundant diffusion and scattering patterns, eliminates glare, reduces numbers of LEDs, and contributes to space saving and cost reductions.

They offer the same weather resistance properties of standard acrylic resins, and can be used both indoors and outdoors. Some products are also listed in the AMECA Diffusing List.

Feature 1: Eliminates glare

Through high diffusion while maintaining transmittance, DELPET™ Light Diffusion / Scattering Series acrylics erase lamp images, eliminating glare to create lighting that is friendly to the eye and improving design characteristics. They also contribute to saving space and reducing costs by reducing numbers of LEDs and.

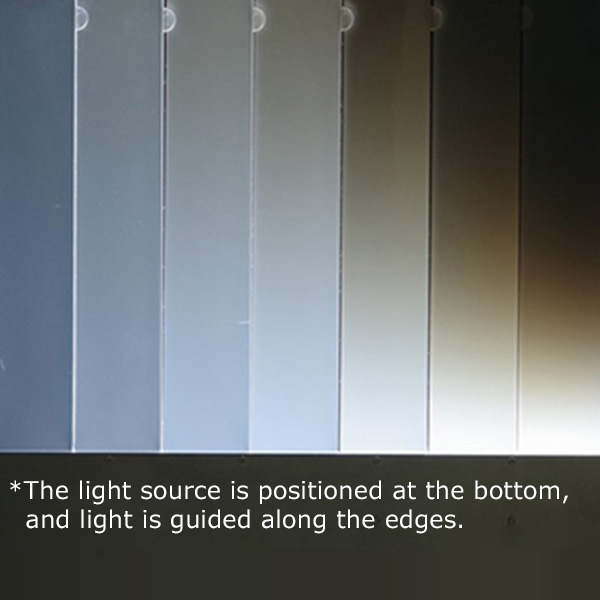

Feature 2: Improved design characteristics

This is a surface light-emission grade that combines high transmittance and light scattering by utilizing particle dispersion technology. With this grade, it is possible to express the gradations envisaged by the designer. Guiding light from the edges makes it possible to make better use of space.

Acrylic resin DELPET™Features

- Luxurious-feeling transparent clarity

- Elegant color tone and luster

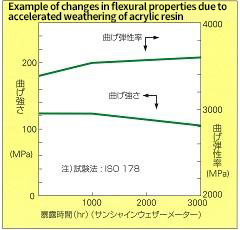

- Excellent weather resistance

- High surface hardness

- Good resistance to chemical agents

Acrylic resin DELPET™Use

Automotive-related

Tail lamp lenses, speedometer covers, side visors, rear-end styling, etc.Electrical and electronics-related

Optical lenses, light guiding plates, light diffusion plates, lighting covers, etc.Others

Lenses (sunglasses, reading glasses, magnifying glasses), accessories, tableware, etc.

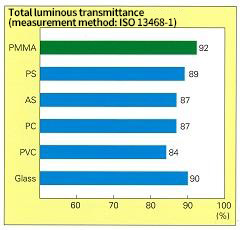

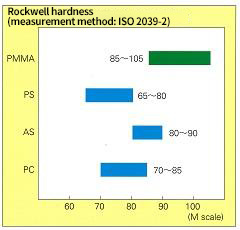

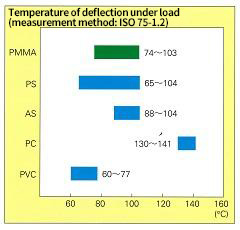

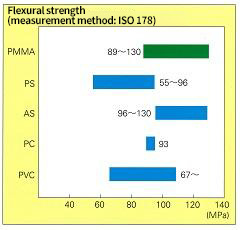

Acrylic resin DELPET™Features of acrylic resin

- Comparison with other transparent materials -

Acrylic resin DELPET™Handling Precautions

- The contents of these materials is based on currently available materials, information and data, and may be subject to revision based on new findings.

(1) Handling precautions

Please be sure to read the DELPET™ Handling Precautions listed in the separate Product Safety Data Sheet (SDS) before using DELPET™. The main points when handling DELPET™ are as follows. Please use them for the safe handling of DELPET™. Please investigate the safety of additives, etc., used by your company aside from DELPET™.(a) Basic handling precautions

There is no risk of DELPET™ igniting at room temperature, but avoid unnecessary use of naked flames in the workplace and endeavor to keep materials organized. Avoid residual buildup, as there is a possibility of dust explosions, and install equipment for removing static electricity in equipment such as air transfer equipment, bug filters, hoppers, etc.(b) Health and safety precautions

The main component of the gas generated during drying, melting and resin decomposition of DELPET™ is methyl methacrylate (MMA), which is the raw material monomer. Take care to avoid contact with eyes or skin, or inhalation. Do not touch high-temperature resin directly. For drying and melting, etc., it is necessary to install local exhaust equipment and wear protective equipment (safety glasses, protective gloves, etc.)(c) Combustion-related precautions

DELPET™ is flammable, and should be handled and stored away from heat and ignition sources. In the event of combustion, incomplete combustion may generate harmful gases such as carbon monoxide. Water, foam, and powder fire extinguishers can be used to extinguish fires involving DELPET™.(d) Precautions when disposing

DELPET™ waste can be disposed of by landfill or incineration. When disposing of waste by landfill, please entrust it to an authorized industrial waste disposal business operator or local government authority in accordance with the Waste Management and Public Cleansing Act. When incinerating waste, use an incineration facility to handle waste in accordance with various laws and regulations such as the Air Pollution Control Act. During incineration, incomplete combustion may generate harmful gases such as carbon monoxide.

Dispose of empty bags appropriately without reuse or repurposing.(e) Precautions when storing

DELPET™ is a designated combustible (synthetic resin) under the Fire Service Act. Handle it in accordance with municipal ordinances (fire extinguishing equipment, indoor storage and handling facilities, etc.).(f) Precautions when molding

To avoid decomposition of resin, please pay attention to the following points.

Do not allow resin to stay in the processing machine for a long time under high temperature conditions.

Do not mix any colorants, additives or other resins with DELPET™ other than those specified by Asahi Kasei. Mixing with other substances may significantly degrade the thermal stability of the resin.

Spilled pellets, etc., left on the floor may lead to slips and falls. Please clean up and remove them immediately.(2) Conforming standards

DELPET™is available in grades that comply with various standards including UL (Underwriters Laboratories Inc.), SAE (Society of Automotive Engineers), and Electrical Appliance and Material Safety Law, etc. There are grades that have received a confirmation certificate (Japan Hygienic Olefin And Styrene Plastics Association type) (or an equivalent confirmation certificate).Conformance to these standards is determined by specific test methods. Safety as a product should be verified after conducting appropriate tests for the application of use.(3) Others

Pay attention to industrial property rights, etc., when using DELPET™.(4) Restrictions on use

Please be sure to contact our representative in advance when using DELPET™ for medical applications, applications involving contact with food and drinking water, cosmetics, toys, sporting goods, and other applications that do not fall under the following prohibited applications of use. We will respond on an individual basis.

[Prohibited applications of use]

Do not use in medical instruments or products that come into contact with human tissues or internal bodily fluids over an extended period (30 days or more), or those that touch the mouths of, or may be swallowed by, infants.