Molding

Molding for  OVERVIEW

OVERVIEW

UHMWPE has long been used in molding applications. Since Asahi Kasei began manufacturing SUNFINE™, it has been supplied for industrial use. It continues to evolve through the exploration of optimal grade designs and quality in accordance with a broad spectrum of individual molding applications.

UHMWPE molded products using SUNFINE™ have excellent impact resistance, wear resistance, chemical resistance, non-adherence and other characteristics. They are employed in many different applications as a marvelous alternative to metals, concrete and other plastics.

MoldingEXAMPLE

MoldingGRADES

| Physical properties | Test method | UH910 | UH950 | QUH972 | |

|---|---|---|---|---|---|

| Molecular weight | - | ASAHI KASEI PE METHOD | 3.3×106 | 4.2×106 | 6.3×106 |

| Bulk density | g/cm3 | Reference Standard:JIS K 6722:1995 | 0.52 | 0.50 | 0.47 |

| Density | kg/m3 | Reference Standard:ISO 1183-2 | 926 | 928 | 924 |

| Particle size d50 | μm | Reference Standard:ISO 13320 Reference Standard:ISO 9276-2 |

170 | 160 | 120 |

| Melting point | ℃ | ISO 11357-3 | 134 | 136 | 134 |

| Prescription of additives | Yes | Yes | Yes | ||

MoldingPROPERTY

-

High impact resistance

The impact resistance of SUNFINE™-molded products is superior to products molded from other engineering plastics.

It is also notable that they retain their high impact resistance even at -40 °C.High impact resistance (-40℃)

-

High wear resistance

High wear resistance

The wear resistance of SUNFINE™-molded products is superior to products molded from other engineering plastics.

-

Very low metal residues and

low contaminationSUNFINE™ is produced under strict plant management conditions that ensure the cleanliness of plants to maintain the high quality of raw materials.

SUNFINE™ is manufactured only in Japan to ensure that strict plant management is implemented to maintain its high quality.

-

High quality stability

Strict manufacturing operations and advanced catalyst technology produce very little variation in physical properties between lots. This makes a major contribution to the production stability of Asahi Kasei's customers.

MoldingFIELD OF USE

-

Impact Resistance

SUNFINE™ exhibits greater impact resistance than other engineering plastic materials and competitive UHMWPEs.

-

Wear Resistance

With very low friction on steel materials, SUNFINE™ has higher wear resistance than other engineering plastic materials and competitive UHMWPEs. Its high wear resistance prevents the wearing of materials that it contacts.

-

Sliding Properties

The impressive sliding properties of SUNFINE™ prevent scratches on product surfaces. This results in a reduction of the noises from conveyance and other processes.

-

Hygiene

Some grades conform to the Specifications and Standards for Food, Food Additives, etc. (Public Notice of the Japanese Ministry of Health and Welfare No. 370 of 1959, in the category of use at a temperature of 100 °C or below).

-

Chemical resistance

SUNFINE™ has excellent corrosion resistance to various chemicals. No deterioration is observed in the physical properties of SUNFINE™ when exposed to most acids, alkalis and organic solvents.

-

Lightweight

SUNFINE™ has a specific gravity from 0.92 to 0.94. It is one of the most lightweight engineering plastics.

MoldingCASE

-

Low coefficient of friction

and high wear-resistanceSUNFINE™ is used in many different applications including linings for silos, hoppers, and other equipment, mechanical parts such as gears and gaskets, blades for farming machines and implements, as well as bulldozers and other machine tool components. We are ready to provide an array of grades to respond to market needs.

-

High impact strength and

low temperature resistanceSUNFINE™ is used in various applications including the running surfaces of skis, snowmobile gear rails and synthetic ice rinks. To further increase its added value, we endeavor to create grades design particularly for individual applications leveraging our strong development capabilities.

-

Hygiene

SUNFINE™ is used in many applications such as guide rails and other sliding components in the food conveyance industry, stirring screws and the linings of freezers. To increase product quality, we strictly control foreign matter and metal residues to ensure that we are able to provide high quality grades with outstanding whiteness.

SUNFINEAPPLICATIONS

-

Lithium-ion Battery Separator

The high quality, optimized grades of SUNFINE™ improve the functions of lithium-ion battery (LiB) separators and achieve their stable production.

-

Lead Acid Battery Separator

Asahi Kasei proposes UHMWPE with low contaminants and stable physical properties to help batteries achieve a high level of safety.

-

High-strength Fiber

Developed from Asahi Kasei's experience supplying industry-leading companies, it offers a distinguished high molecular weight grade that helps achieve the functional enhancement of fibers.

-

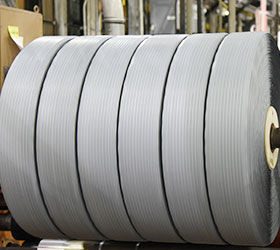

Molding

Asahi Kasei offers several grades suited for molding applications. They contain a low level of foreign matter and have high whiteness. Some grades meet standards for food applications.