Asahi Kasei Medical ESH Policy

Environmental safety activities are one of the important management foundations of the Asahi Kasei Group, and we are working on activities in all business areas including the medical business field. We carry out voluntary management activities that consider the environment and safety throughout the entire product life cycle, from development to manufacturing, distribution, use, final consumption, and disposal.

We, Asahi Kasei Medical, recognize that themes such as occupational safety, security and disaster prevention, environmental conservation, and the global environment are the most important management issues from the perspective of social corporate responsibility.

Employees' health and comfortable workplace

Physical and mental health

We promote physical exercise and the revision of operational procedures to prevent falling and backache. We also provide physical check-up to prevent employees from falling.

We implement an intranet-based electronic diagnosis annually for employees to promote their mental health well. Specifically, we are continuously improving the workplace culture based on the results of the e-diagnosis in both the factory area and the head office area.

Workplace patrols, 5S activities

We regularly patrol the workplace and actively develop 5S activities such as tidiness/orderliness/cleaning/cleanliness/discipline to promote the creation of a comfortable working environment.

Safety of personnel and community

Workplace safety

With the goal of zero occupational accidents, we conduct risk assessment activities, proposal activities from near misses, and basic safety behavior compliance activities.

For examples of compliance activity,: we conduct equipment improvements such as installing handrails in offices and factories: we call out for attention with speakers: we are displaying a warning, in order to ensure that "when going up and down stairs, hold the handrails and pay attention to your feet".

Traffic safety

We provide risk awareness trainings for domestic sales, which leads to hazard avoidance when driving.. In addition, we conduct some other activities such as reviewing case studies.

Prevention from caught in/between

At the Oita Works, we have been taking measures against dangerous parts such as being caught in/between on each workplace. We have started mutual check to/from other workplaces since 2021. We will ensure intrinsic safety and safety protection through these repeated checks.

VR disaster experience system

It allows users to experience accidents realistically or visually that we cannot really experience, and it appeals to people's instincts more than conventional experience devices. We use this system in conjunction with conventional methods to improve employee safety awareness and safety sensitivity.

ESH Audit

Every year, we conduct ESH audits of 10 departments in Japan and overseas including affiliated companies, to make sure the status of safety management at each factory.

At each plant, we have confirmed that the PDCA cycle is being circulated reliably for each ESH item, and that each safety level is being improved.

ESH & QA (Quality Assurance) Symposium

We all think about safety and renew our will through it.

In 2022, we held the symposium in November with approximately 200 people. We had some speeches from guests including the president of Asahi Kasei Medical, and activity reports on ESH & QA. In addition, group activities were presented. After commitments were expressed by the plant managers, the symposium was completed with safety slogans.

Reduction of the environmental burden

Reduce and recycle of industrial waste

We are working to reduce and recycle industrial waste. Currently, the total amount of industrial waste is approximately 5,000 tons/year, and the amount of plastics is approximately 1,500 tons/year. Plastics were reduced by approximately 300 tons compared to last year. In the future, we will aim to reduce emissions by promoting measures such as further promoting recycling through separation of composite materials.

Against global warming

We reduced greenhouse gas emissions by improving production efficiency with factory consolidation from 2016 to 2019.

Greenhouse gas emissions in 2022 have been reduced by about 20% compared to 2016. The energy intensity has also improved by about 40% compared to 2016. It is expected to receive the highest evaluation for the fifth consecutive year in the business classification evaluation from Agency for Natural Resources and Energy, Japan.

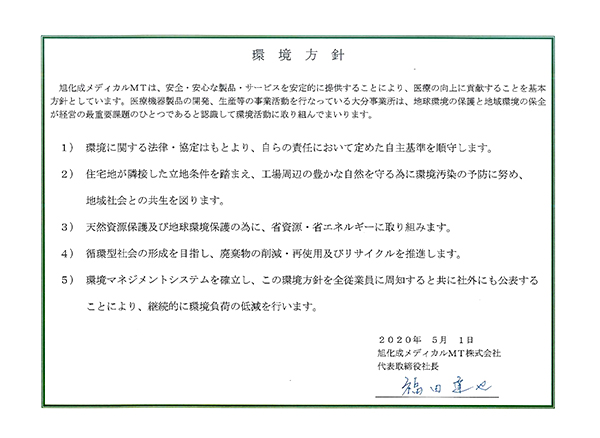

Environmental protection activity of Asahi Kasei Medical MT

Asahi Kasei Medical MT continues to improve its environmental management system and implements activities that comply with ISO14001: 2015. In 2021, the Oita Works changed its certification body with the aim of further development.

The environmental policy of the Oita Works is presented below.

Symbiosis with the community

We do our best to meet the needs of the local community, such as that we dispatch instructors and that we accept students for practical training, based on requests from schools. In addition, in response to requests from the Red Cross Blood Center, we provide locations and encourage employees to donate blood there.

In addition, Asahi Kasei Medical MT issues an environmental safety report every year, and distribute it to the local community.