3DCAD

-

With 3D CAD (3D Computer Aided Design), model data of various shapes of products can be designed in 3D using a computer.

This significantly reduces the time required compared with the traditional method.We were early to adopt 3D CAD, utilizing it in product development, mold making, and CAE simulation.

Please contact us regarding compatible file formats.

-

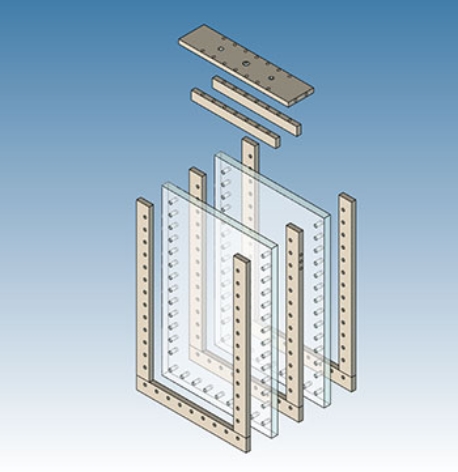

CAE simulation

-

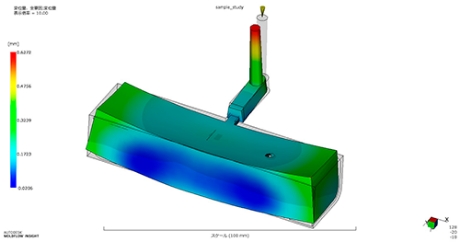

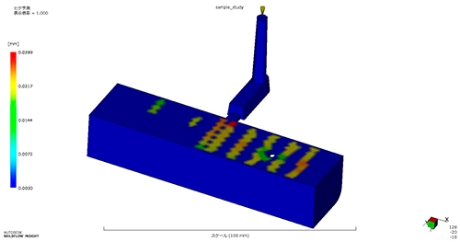

CAE (Computer Aided Engineering) is used to perform injection molding simulation at the product design phase.

There are various different simulations.

CAE simulation offers many advantages for plastic parts, including improved design accuracy, reduced time for making molds, and reduced cost.- Flow simulation

- Dwell pressure simulation

- Cooling simulation

- Warp / distortion simulation

- Optimum runner and gate location simulation

- Gas injection simulation etc…

We use Autodesk’s Moldflow to raise the efficiency of design for customers.

-

Mold Machining

-

The quality of injection molding is highly dependent on the accuracy of the mold.

Our molds are made by subcontractors with whom we have long-standing relationships.After detailed discussions, molds are made reflecting the results of CAE simulation and experience accumulated over time.

Dirt and deterioration of a mold directly affect molding quality.We manage molds for long-term trouble-free use, by adopting structures that allow easy maintenance and cleaning them thoroughly on a regular basis.

-

AMOTEC Molding

-

Dissolved in resin, CO2 acts as an excellent plasticizer.

AMOTEC (Asahi Kasei Molding Technology with CO2) imparts resin with various useful properties.

For weight reduction, it enables foaming with CO2 and the molding of thinner walls with improved flowability.

It also improves the precision of fine shape transfer.AMOTEC is particularly suited to molding lightweight foamed products with outstanding external appearance, as it suppresses the generation of a foam pattern on the surface layer.

-

Gas Injection

-

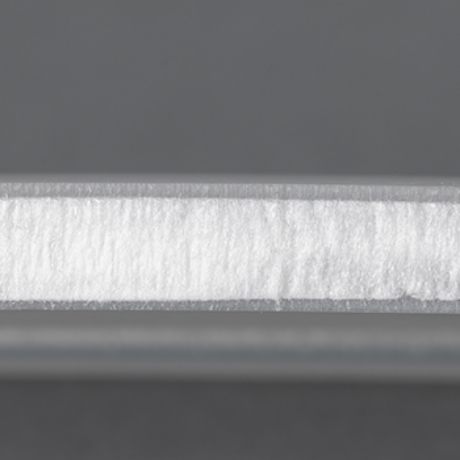

We have AGI (Asahi Kasei Gas Injection), gas injection technology developed by Asahi Kasei. AGI uses nitrogen gas to apply dwell pressure to resin after injection into the mold.

AGI forms a hollow cavity within the molding where shrinkage tends to occur, resulting in lighter parts with less distortion, sink marks, and warpage.

-

Double Shot Molding

-

Two color injection molding is a method to combine two colors or different kinds of resin to produce a single integrated piece.

Using a double shot injection molding machine, it is basically an automatic, single-cycle process providing high productivity and consistency.

Steps in the cycle are as follows:- Resin is injected into mold A from the first injection unit

- With the part molded from first injection attached, mold A is rotated to the second injection unit

- After clamping, resin is injected into mold A from the second injection unit and into mold B from the first injection unit

- After cooling, the finished product removed from mold A on the second injection side

- Mold A is rotated back to the first injection side, and mold B is rotated to the second injection unit with the part molded from the first injection attached

- Injection, rotation, and removal are repeated

Since the two different materials are automatically bonded together, the number of parts and number of assembly steps are reduced, enabling lower cost and lighter weight.

The use of two different materials also allows broader variation in design for greater functionality or enhanced appearance.

Assembly / Printing / Coating

-

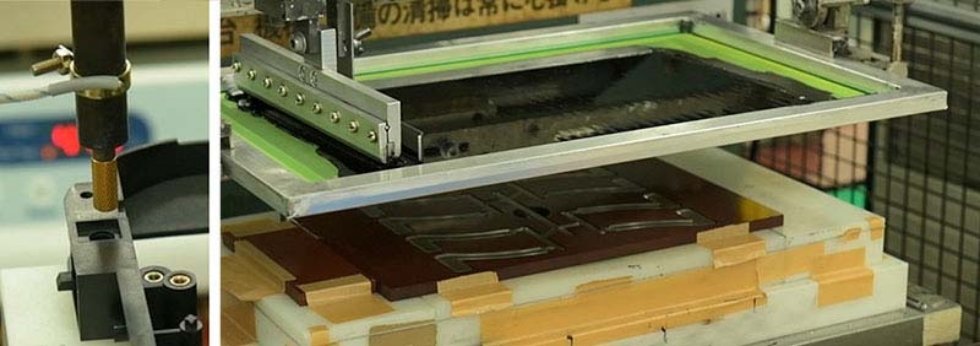

In addition to molding, we can also perform assembly, printing, and coating.

At our Saitama Plant, we assemble plastic products as well as illuminated license plates.

We can satisfy various requests by leveraging a broad range of experience in assembly.Assembly : Press-fitting of various inserts, fastening with screws, welding, taping, etc. Printing : Pad printing, screen printing, inkjet printing, etc. Coating: : Robotic spray coating, spindle coating, vapor deposition, plating, etc. -

-

We can perform measurements on a wide range of products using our rich array of measuring equipment, including a coordinate measuring machines, laser microscope, micrometer, and film thickness tester.

We also use external organizations to perform product evaluation. -