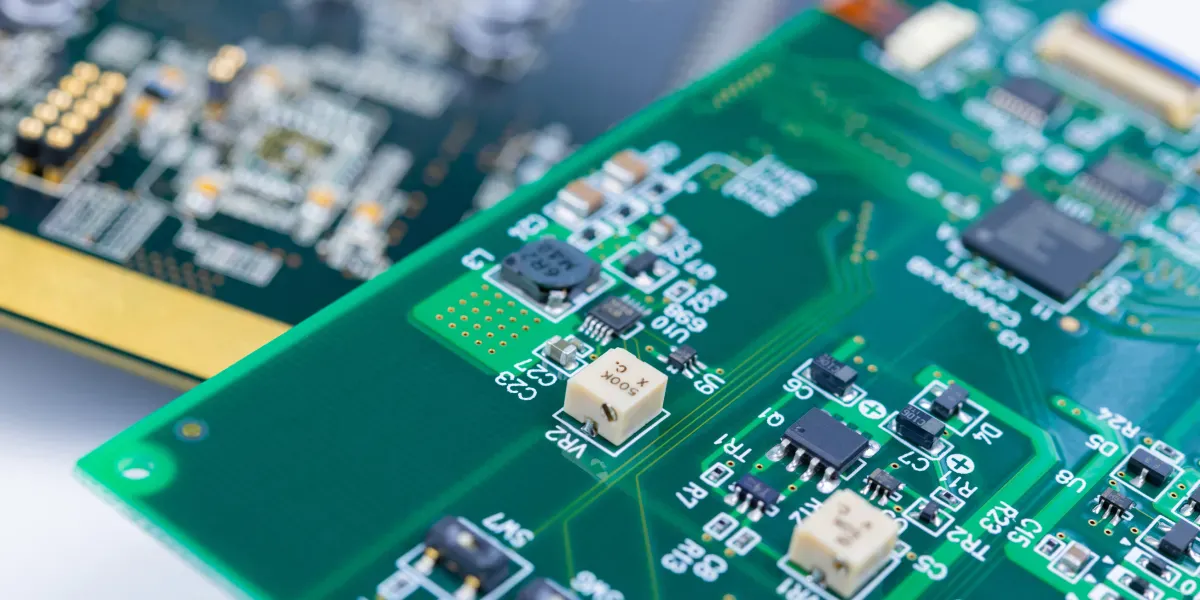

Achieve Superior Dielectric Properties in Substrate Materials with TUFTEC™ and S.O.E.™

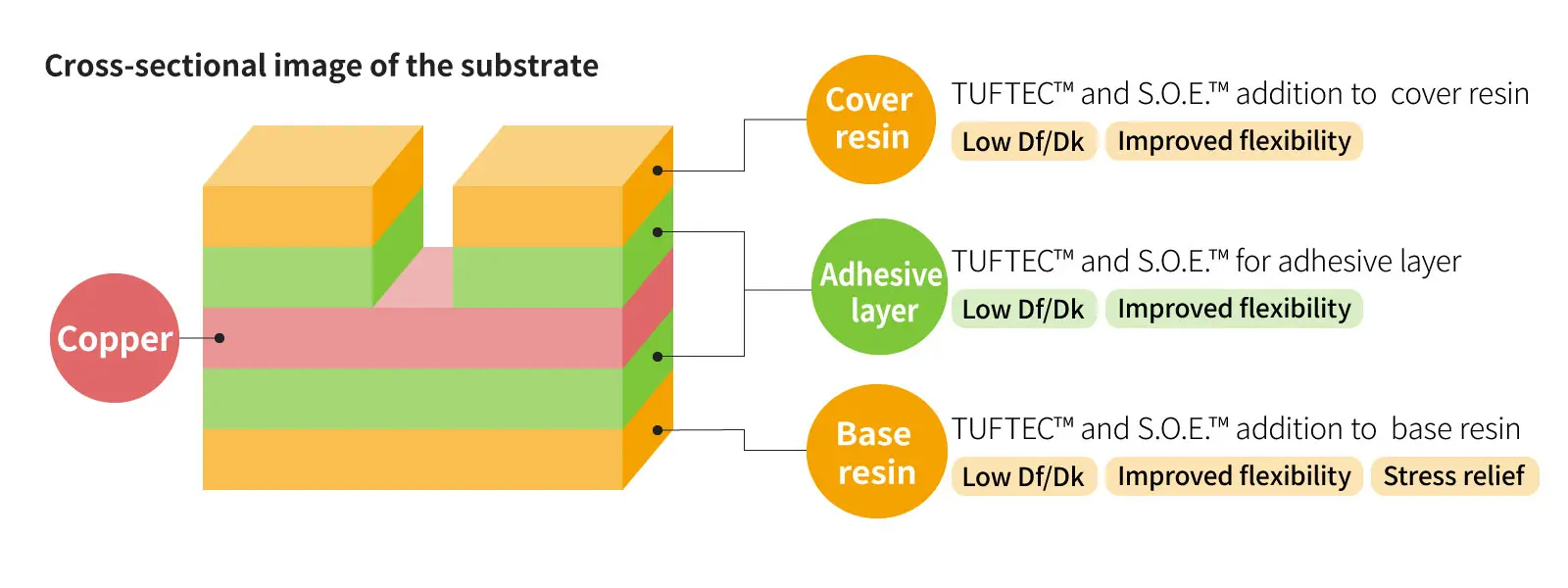

Asahi Kasei's TUFTEC™ and S.O.E.™ can be incorporated as additives into substrate materials to impart excellent dielectric properties and enhance adhesion to copper foil. They also allow for balanced control of various properties required for substrate materials, such as heat resistance and processability, enabling the realization of highly functional substrate materials.

Reduce Transmission Loss in Substrate Materials with Low Dielectric Constant and Low Dissipation Factor

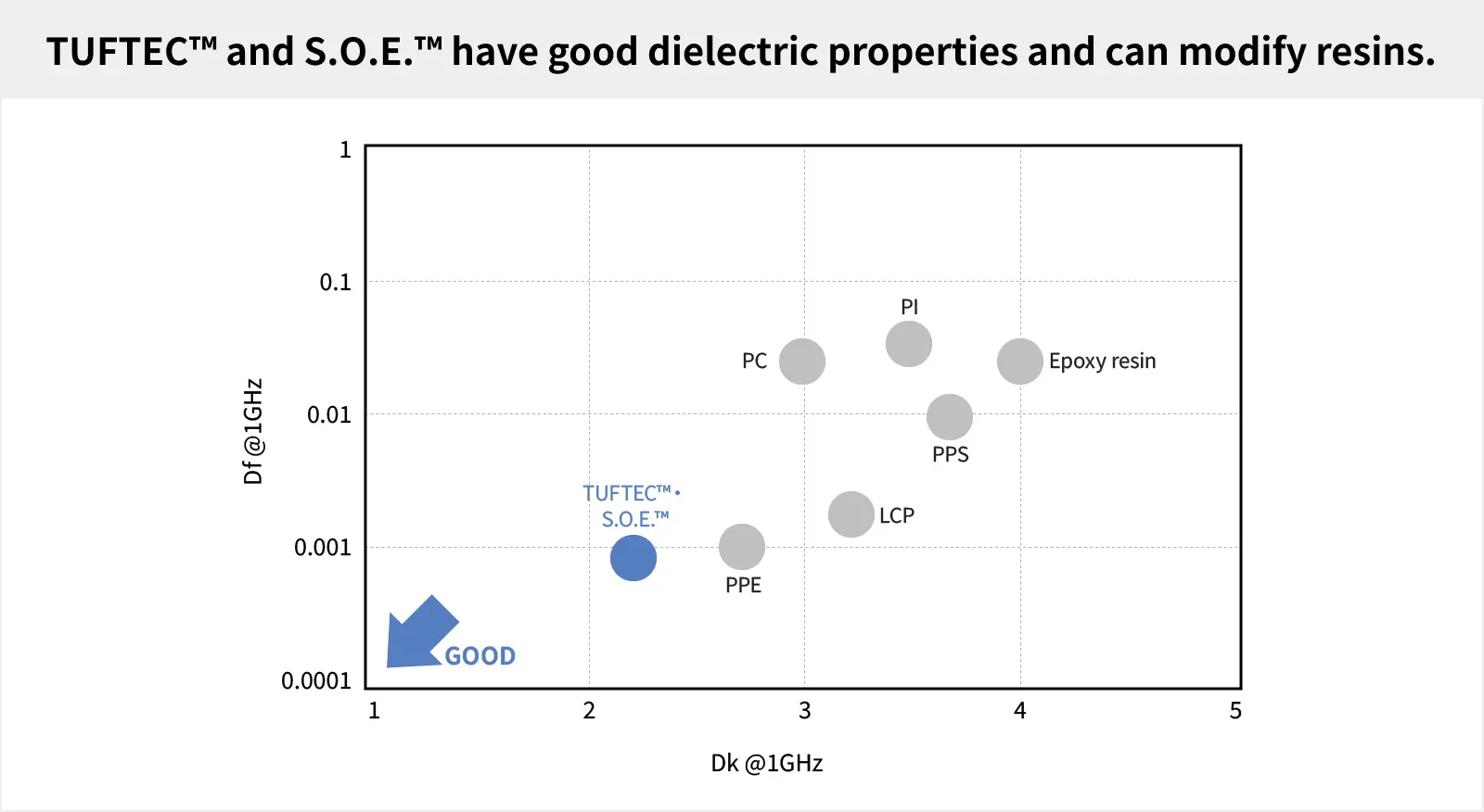

In recent years, communication devices such as smartphones and base station equipment have been increasingly demanded to handle higher communication speeds and larger data volumes. This necessitates support for higher frequencies. However, transmission loss is dependent on communication frequency, meaning that higher frequencies result in greater transmission loss compared to traditional frequencies.

To reduce transmission loss in the high-frequency band, it is effective to reduce the dielectric constant and dissipation factor of the substrate material.

TUFTEC™ and S.O.E.™ can be added to PPE and epoxy resins, traditionally used as substrate materials, as modifiers to impart excellent dielectric properties to the substrate material. This allows for reduced transmission loss in the high-frequency band.

Balanced Control of Various Properties Required for Substrate Materials

-

Enhanced Adhesion to Copper Foil:To improve transmission efficiency, the surface of the copper foil in the substrate needs to be smoothed. However, the smoother the surface of the copper foil, the lower the adhesion between the copper foil and the base material. Therefore, incorporating flexible TUFTEC™ or S.O.E.™ to impart adhesiveness to the substrate material allows for improved adhesion to the smoothed copper foil. This enables the production of substrate materials with high transmission efficiency and adhesive strength.

-

Maintain Heat Resistance:Generally, adding elastomers to improve dielectric performance and adhesion to copper foil can lead to a decrease in heat resistance, causing the resin to deform or a CTE increase resulting in warping of the substrate. However, TUFTEC™ and S.O.E.™ allow for crosslinking with thermosetting resins, enabling the maintenance of heat resistance and CTE. This enables the development of substrate materials that are both heat-resistant and have excellent dielectric performance and adhesion.

-

High Solubility in Solvents:TUFTEC™ and S.O.E.™ exhibit excellent solubility in solvents such as toluene and methyl ethyl ketone (MEK). This allows them to be dissolved in an organic solvent along with thermosetting resins and fillers for the production of varnishes during resin film and prepreg manufacturing.

-

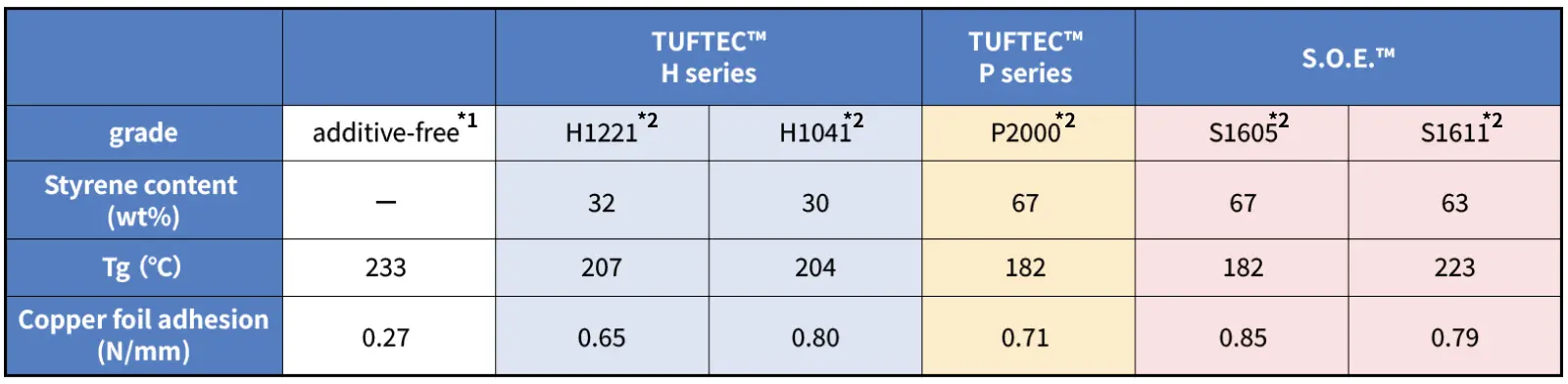

High Compatibility with Thermosetting Resins:TUFTEC™ and S.O.E.™ offer a variety of grades with different styrene contents. This enables the selection of the optimal grade based on the type of thermosetting resin used in the substrate material.

Recommended Grades: Contact Us for Inquiries

The recommended grade for substrate material applications varies depending on the customer's requirements. We will first listen to your performance requirements and propose the optimal grade. Please feel free to contact us. Asahi Kasei's extensive product lineup and wide range of molecular design technologies will support your problem-solving efforts.