Contributing to the Solution of Diverse Challenges

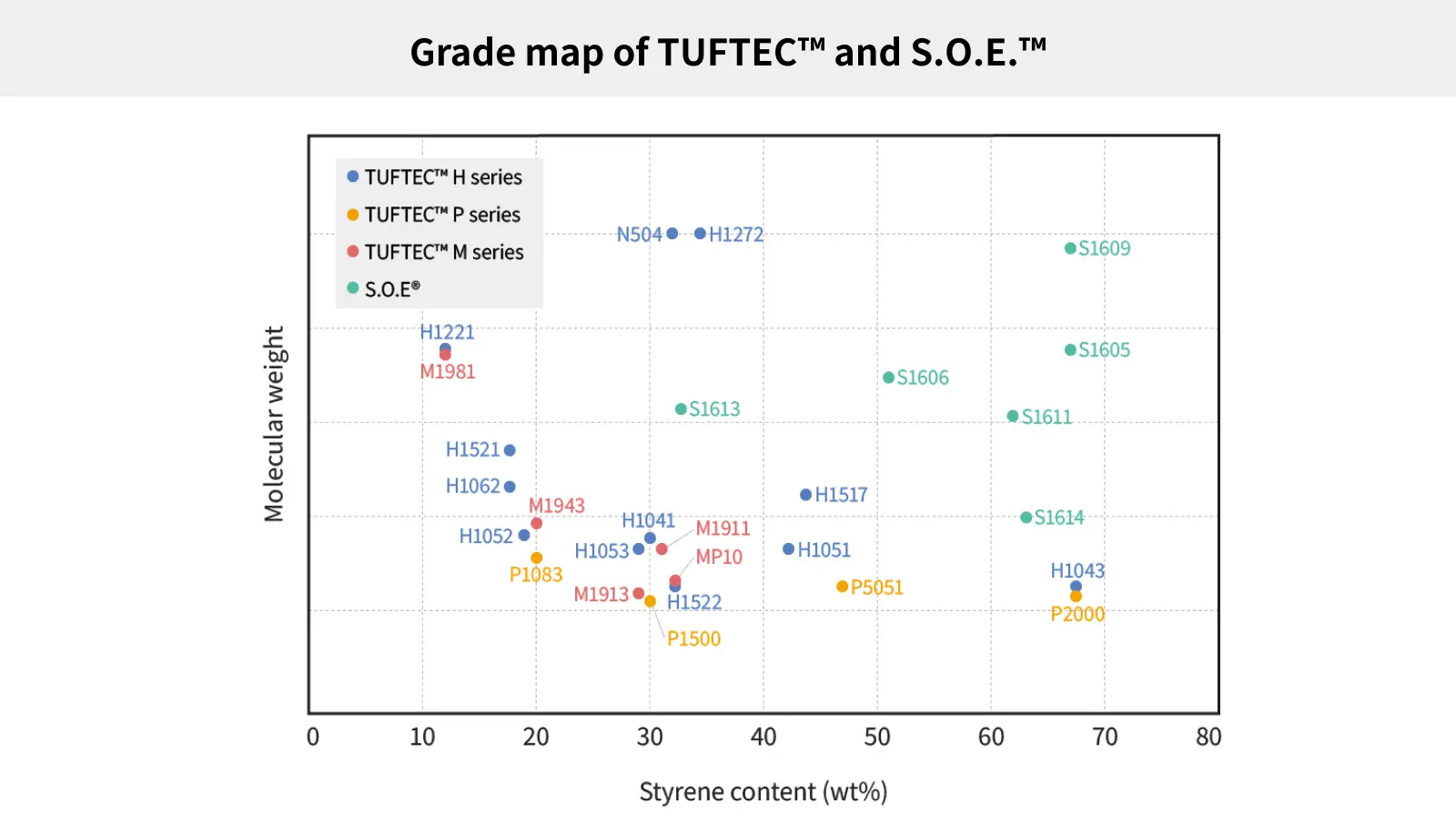

We offer a wide range of product lines, including the H Series for TUFTEC™ that excels as a modifier and compatibilizer, the M Series for modified types, the P Series that boasts superior low-temperature performance, processability, and high resilience, and the S.O.E.™ known for its excellent abrasion resistance and shock absorption.

Details of Asahi Kasei's SEBS

Asahi Kasei's SEBS Series Lineup

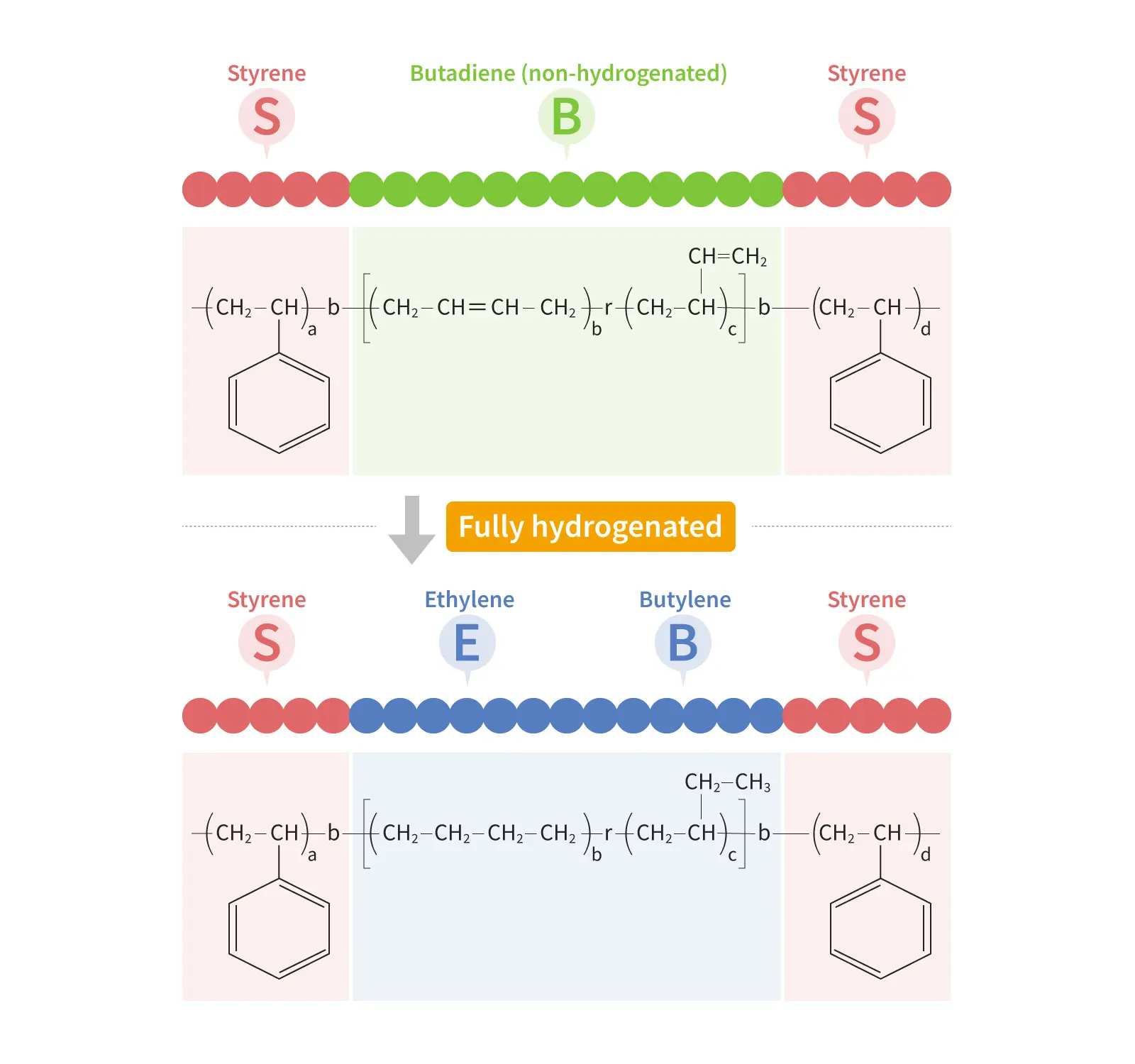

TUFTEC™ and S.O.E.™ are hydrogenated (hydrogen added) to the double bonds in the polybutadiene that forms the soft block. We offer a full range of fully hydrogenated TUFTEC™ H Series, modified M Series, selectively hydrogenated P Series, and S.O.E.™ with copolymer-type soft blocks.

Asahi Kasei's SEBS Offers a Wide Range of Low to Medium Molecular Weight Grades, from Standard to Unique

Asahi Kasei's SEBS boasts a wide range of low to medium molecular weight grades with exceptional functionality and processability as its strengths. TUFTEC™ features three series that utilize hydrogenation rate control and modification techniques. Additionally, we offer a diverse selection of products, ranging from flexible low styrene grades to rigid high styrene grades.

S.O.E.™ is a unique material that exhibits flexibility despite its high styrene content. It excels in stress relaxation and offers a pleasant tactile feel similar to soft PVC. We propose the optimal grade that best suits your application and desired properties.

SEBS Achieves Superior Weather Resistance and Heat Stability Through Hydrogenation

Hydrogenated styrene-based thermoplastic elastomer SEBS is composed of rigid blocks (S) derived from styrene and soft blocks (EB) derived from butadiene. By hydrogenating the butadiene chain (B) that forms the soft block, double bonds are transformed into single bonds. This hydrogenation process enables SEBS to exhibit outstanding performance unattainable by SBS.