Achieve Superior Crosslinkability

with Selective Hydrogenation Technology

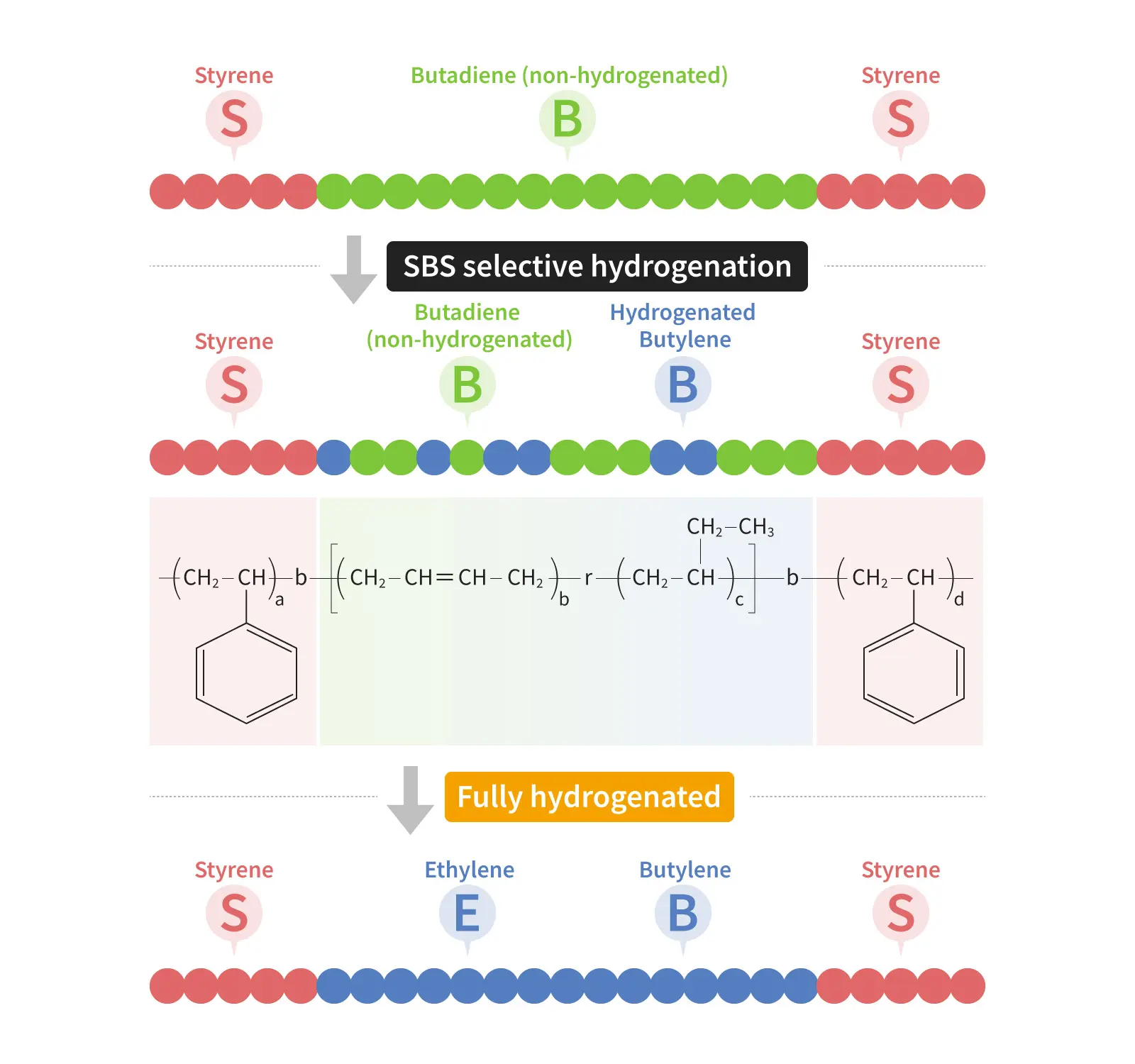

The TUFTEC™ P series is a special type of styrene-based thermoplastic elastomer (SBBS) with selective hydrogenation using Asahi Kasei’s proprietary technology. Compared to non-hydrogenated SBS, it offers superior thermal stability, while compared to fully hydrogenated H series, it exhibits excellent low-temperature performance, processability, and crosslinkability.

Details of the TUFTEC™ P Series

Selective Hydrogenation Delivers Exceptional Impact Resistance and High Rebound Resilience

The TUFTEC™ P series is a styrene-based thermoplastic elastomer (SBBS) with partially hydrogenated butadiene-derived flexible blocks, making it a unique grade developed by Asahi Kasei. Compared to non-hydrogenated types, SBBS offers superior thermal stability. Meanwhile, compared to fully hydrogenated H series, it is characterized by higher low-temperature performance, processability, and crosslinkability. These exceptional properties make the TUFTEC™ P series suitable for various products demanding improved impact resistance and rebound resilience.

Features of the TUFTEC™ P Series

Excellent Crosslinkability

Impact Resistance at Low Temperatures

Low Dielectric Properties

High Flexibility

Resistance to Oxidative Degradation, UV Resistance

Processability

Track Record of Applications for the TUFTEC™ P Series

Grade List of the TUFTEC™ P Series

| Measurement Conditions | Unit | P1083 | P1500 | P5051 | P2000 | ||

| Density | ISO 1183 | g/cm3 | 0.91 | 0.93 | 0.96 | 0.99 | |

| Styrene | Asahi Kasei Method | wt% | 20 | 30 | 47 | 67 | |

| MFR | 230°C・ 2.16kg |

ISO 1133 | g/10 minutes | 14.2 | 34.7 | 16.9 | 24.7 |

| A Hardness | 0s | ISO 7619 | - | 61 | 79 | >90 | >90 |

| 10s | 59 | 74 | >90 | >90 | |||

| D Hardness | 0s | ISO7619 | - | 42 | 66 | ||

| 10s | 42 | 65 | |||||

| Tensile Properties | 100%Mo. | ISO 37 | MPa | 1.7 | 2.1 | 8.5 | Break |

| 200%Mo. | MPa | 2.1 | 2.1 | 8.8 | Break | ||

| 300%Mo. | MPa | 2.7 | 2.2 | 10.2 | Break | ||

| Tensile Strength at Break | MPa | 11.0 | 3.6 | 31.1 | 24.7 | ||

| Elongation at Break | % | 730 | 1,168 | 646 | <100 | ||

| Melt Viscosity (200°C) |

122(1/s) | Asahi Kasei Method | Pa・s | 900 | 435 | 468 | 382 |

| 1.216(1/s) | 306 | 142 | 266 | 161 | |||

| Melt Viscosity (230°C) |

122(1/s) | Asahi Kasei Method | Pa・s | 439 | 163 | 224 | 178 |

| 1.216(1/s) | 191 | 68 | 84 | 52 | |||

| tanδ Peak Temperature | Torsion Mode, 1Hz |

°C | -52 | -67 | -66 | -69 | |

| Refractive Index | JIS K 7142 | - | 1.50 | 1.52 | 1.54 | 1.59 | |

| Product Form | - | - | Pellets | ||||