Widely used for impact absorption and wear resistance.

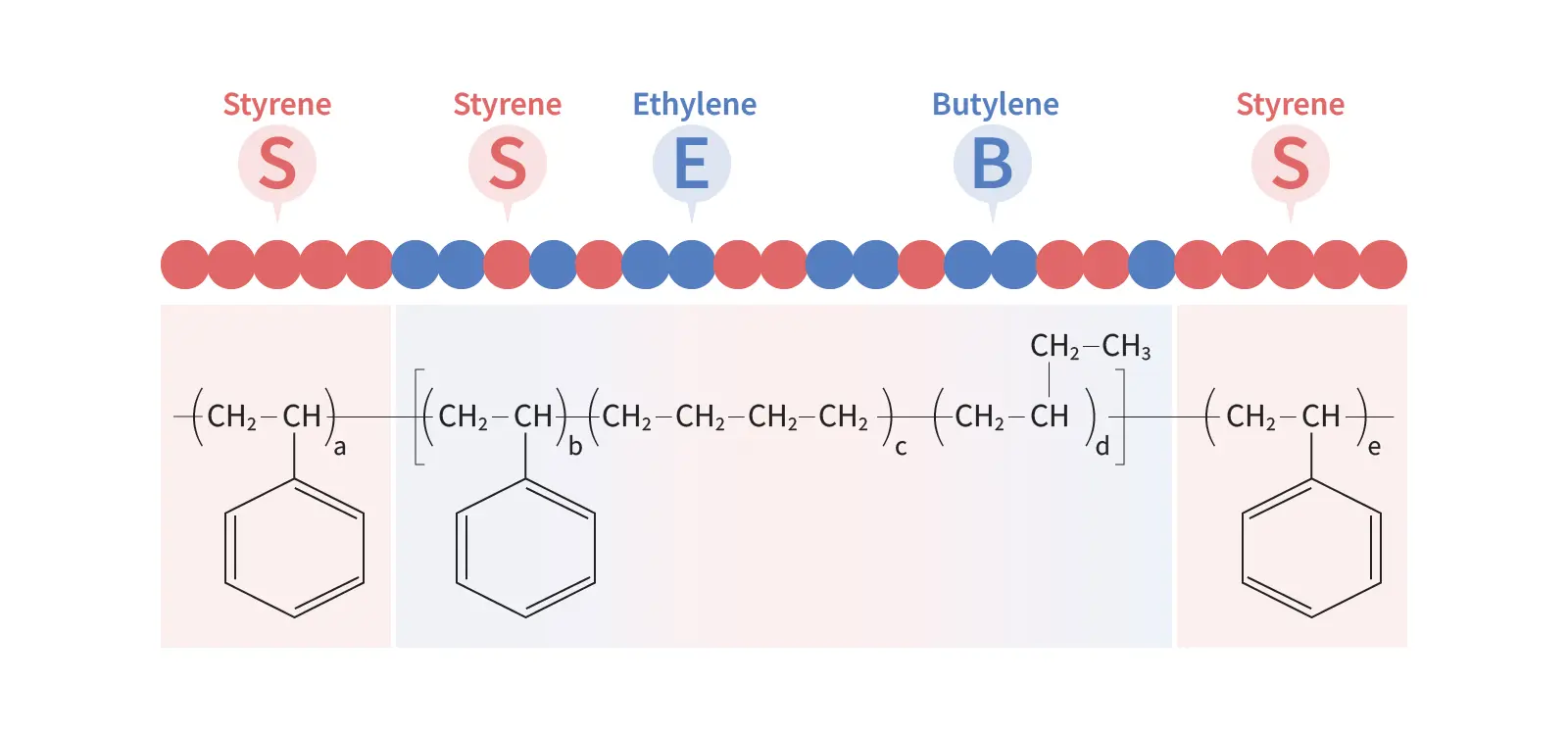

S.O.E.™ is a special SEBS with a copolymer-type soft block. It exhibits a wide tanδ peak near room temperature, making it ideal for various applications that require vibration damping, impact absorption, and wear resistance in this temperature range. These applications include automotive interiors, footwear, and food packaging containers.

Learn More About S.O.E.™

Realizing unique properties such as vibration damping, impact absorption, and wear resistance

Unlike TUFTEC™, S.O.E.™ has a copolymer soft block, resulting in a glass transition temperature (tanδ absorption) near room temperature. This enables it to exhibit vibration damping, impact absorption, and wear resistance within this temperature range. It also boasts excellent compatibility with fillers (filler filling property). As with TUFTEC™, selective hydrogenation types are available, allowing for crosslinking. It delivers a soft touch akin to soft PVC without requiring plasticizers.

Features of S.O.E.™

High flexibility

Vibration damping

High filling of inorganic filler

Wear resistance

Impact absorption

Soft touch

Applications of S.O.E.™

S.O.E.™ Grade List

| Measurement conditions | Unit | S1605 | S1606 | S1609 | S1611 | S1613 | S1614 | ||

| Hydrogenation | - | - | Complete | Complete | Selective | Selective | Complete | Complete | |

| Density | ISO 1183 | g/cm3 | 1.00 | 0.96 | 1.02 | 1.00 | 0.93 | 0.99 | |

| Styrene | Asahi Kasei method | wt% | 67 | 51 | 67 | 63 | 33 | 64 | |

| MFR | 230°C・ 2.16kg |

ISO 1133 | g/10min | 4.7 | 4.5 | 9.4 | 12.3 | 11.4 | 100.0 |

| Shore A hardness | 0s | ISO 7619 | - | 82 | 63 | 82 | 73 | 46 | >90 |

| 10s | 67 | 60 | 62 | 63 | 43 | 85 | |||

| Shore D hardness | 0s | ISO 7619 | - | 25 | 41 | ||||

| 10s | 23 | 35 | |||||||

| Tensile properties | 100%Mo. | ISO 37 | MPa | 3.5 | 2 | 2.5 | 2.3 | 0.9 | 5.8 |

| 200%Mo. | MPa | 7.8 | 2.8 | 3.4 | 3.2 | 1.2 | 8.2 | ||

| 300%Mo. | MPa | 15.4 | 4.3 | 4.9 | 4.7 | 1.5 | 13.8 | ||

| Tensile strength | MPa | 28.8 | 17.0 | 17.8 | 25.0 | 15.5 | 27.9 | ||

| Elongation at break | % | 400 | 466 | 602 | 574 | 740 | 447 | ||

| Melt viscosity (200°C) |

122(1/s) | Asahi Kasei method | Pa・s | 1,444 | 2,338 | 920 | 1,089 | 1,161 | 312 |

| 1.216(1/s) | 318 | 527 | 207 | 276 | 257 | 145 | |||

| Melt viscosity (230°C) |

122(1/s) | Asahi Kasei method | Pa・s | 876 | 1,407 | 597 | 590 | 549 | - |

| 1.216(1/s) | 217 | 392 | 160 | 208 | 175 | - | |||

| tanδ peak temperature | Torsion mode, 1Hz |

°C | 17 | -14 | 17 | 5 | -16 | 20 | |

| Refractive index | JIS K 7142 | - | 1.56 | 1.54 | 1.57 | 1.56 | 1.52 | 1.55 | |

| Product form | - | - | Pellets | ||||||