Achieve High Value-Added Interior Trim with S.O.E.™

S.O.E.™ is widely used as a raw material for styrene-based elastomer (TPS) compounds used in interior trim. It enhances various properties of interior trim, such as tactile feel, appearance, abrasion resistance and scratch resistance. It also contributes to the recyclability of interior trim parts through "core back injection foaming molding".

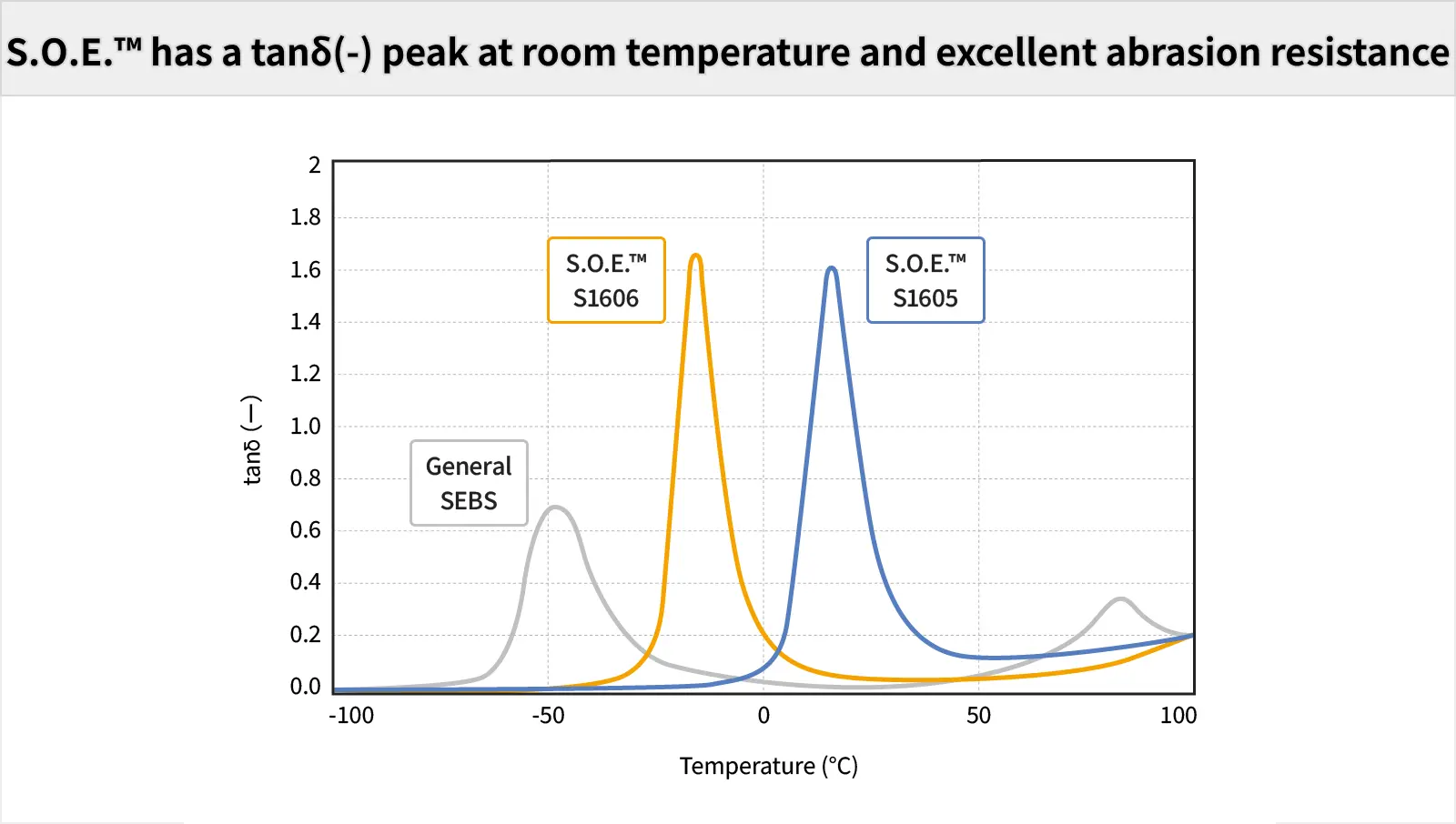

S.O.E.™ Provides Interior Trim with Excellent Tactile Feel and Abrasion Resistance

S.O.E.™ is a material that has a glass transition temperature (tanδ peak) at room temperature, resulting in a significant stress relaxation at room temperature. By using S.O.E.™ as a raw material, you can enhance the TPS compound with an excellent tactile feel and abrasion resistance/scratch resistance, leading to high-value-added interior trim.

Furthermore, the trim parts which is previously required painting due to insufficient abrasion resistance, it may be possible to consider a paint-free design.

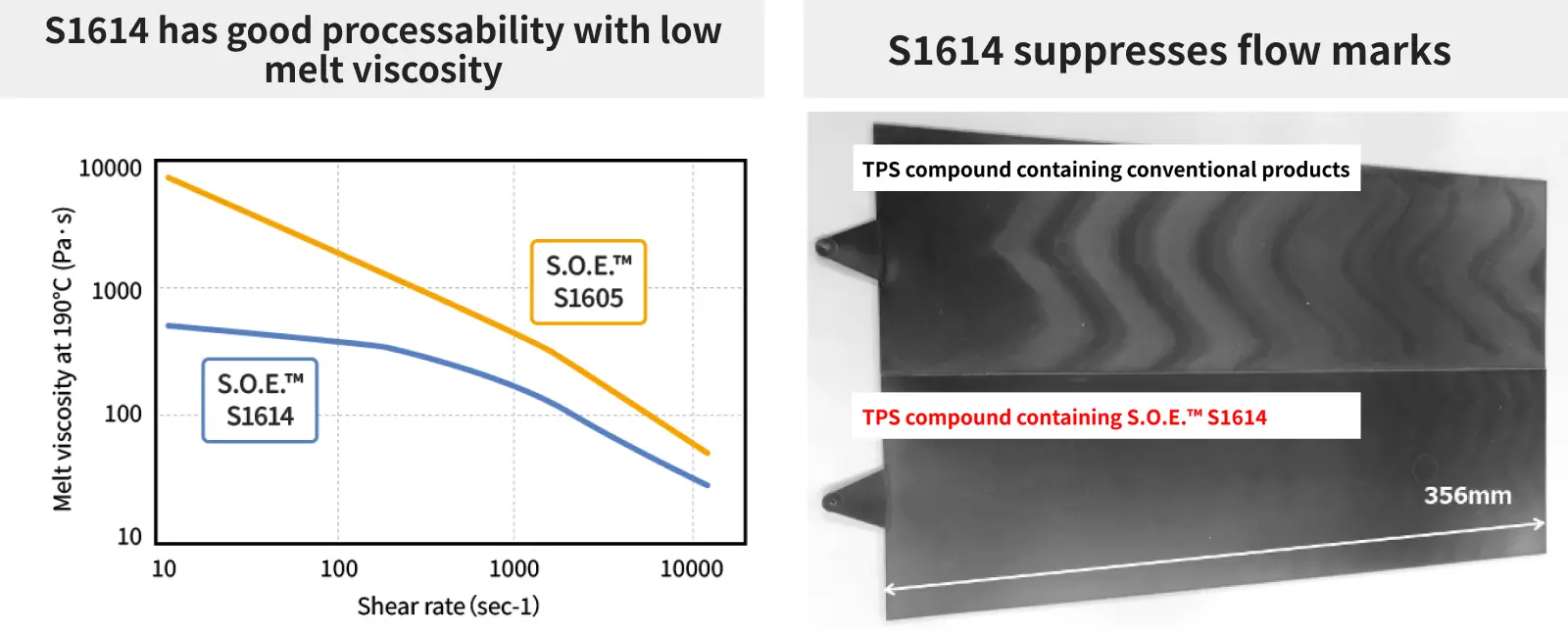

New S.O.E.™ Grades Enable Molding of Large Trim Parts

Styrene-based elastomer (TPS) compounds can be injection molded, and compared to other methods such as extrusion vacuum molding, they offer advantages in terms of molding cycle time, environmental friendliness, and cost. However, if the TPS compound has low fluidity, molding defects such as short shots and flow marks may occur when molding large, complex shaped trim parts. Also, in general, when trying to improve the fluidity of TPS compounds, the abrasion resistance and mechanical strength may decrease, making it difficult to meet the standards for interior trim.

S.O.E.™ S1614 is a grade with significantly improved fluidity. With S1614, the fluidity of the TPS compound can be increased. Moreover, it exhibits abrasion resistance and mechanical strength equivalent to other S.O.E.™ grades. These advantages enable the molding of large trim parts with complex shapes.

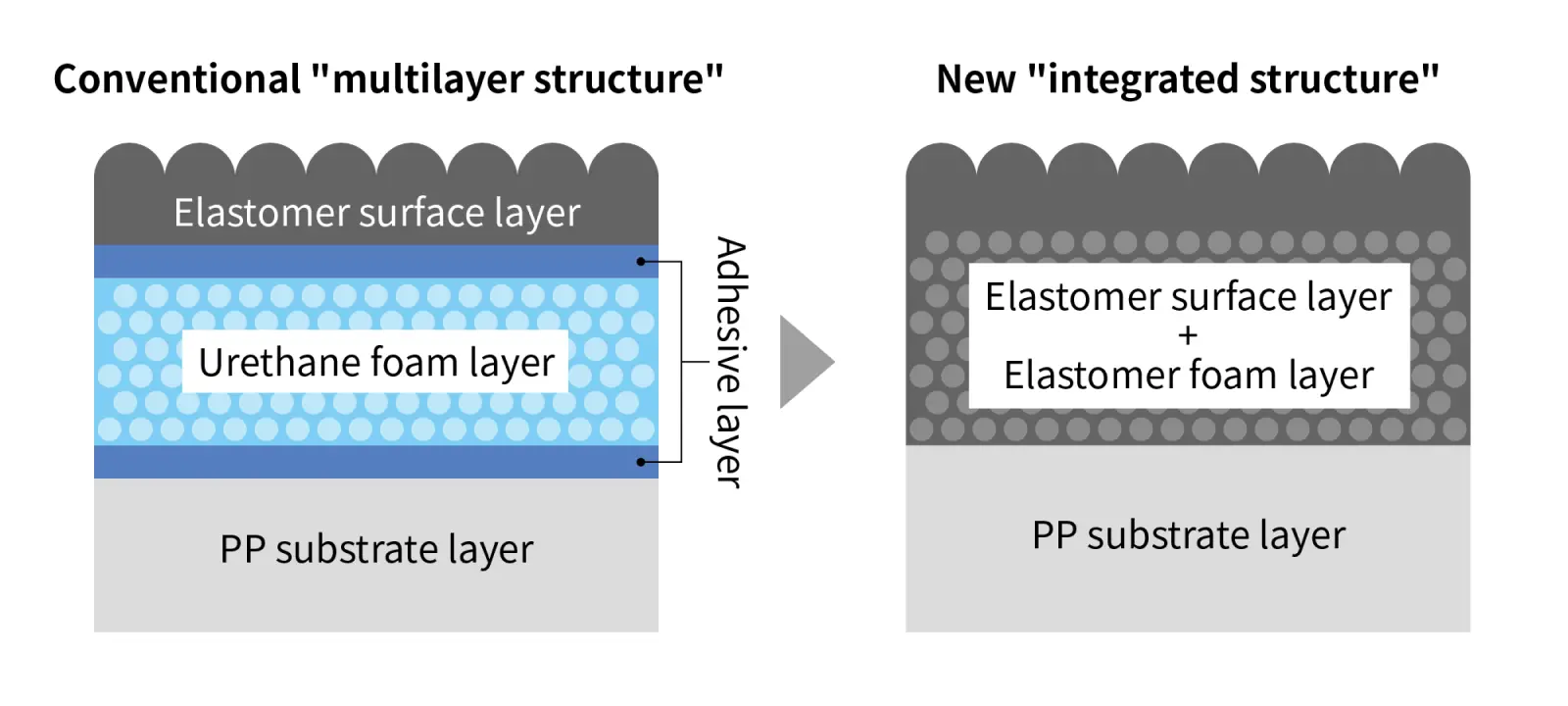

S.O.E.™ Enhances the Recyclability of Interior Trim Parts

Typically, soft interior trim materials incorporate a urethane foam layer between the base layer and the trim layer, achieving a comfortable tactile feel and a sense of luxury. However, the urethane in the foam layer and the TPS compound in the trim layer are incompatible, leading to the challenge of separating each layer when recycling the interior trim materials.

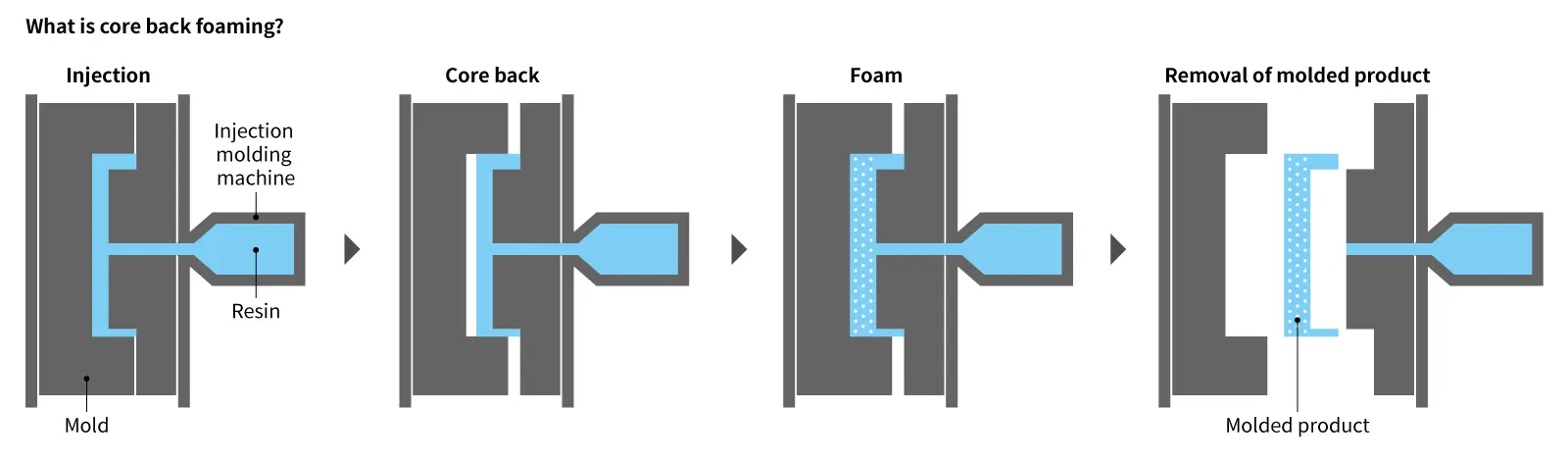

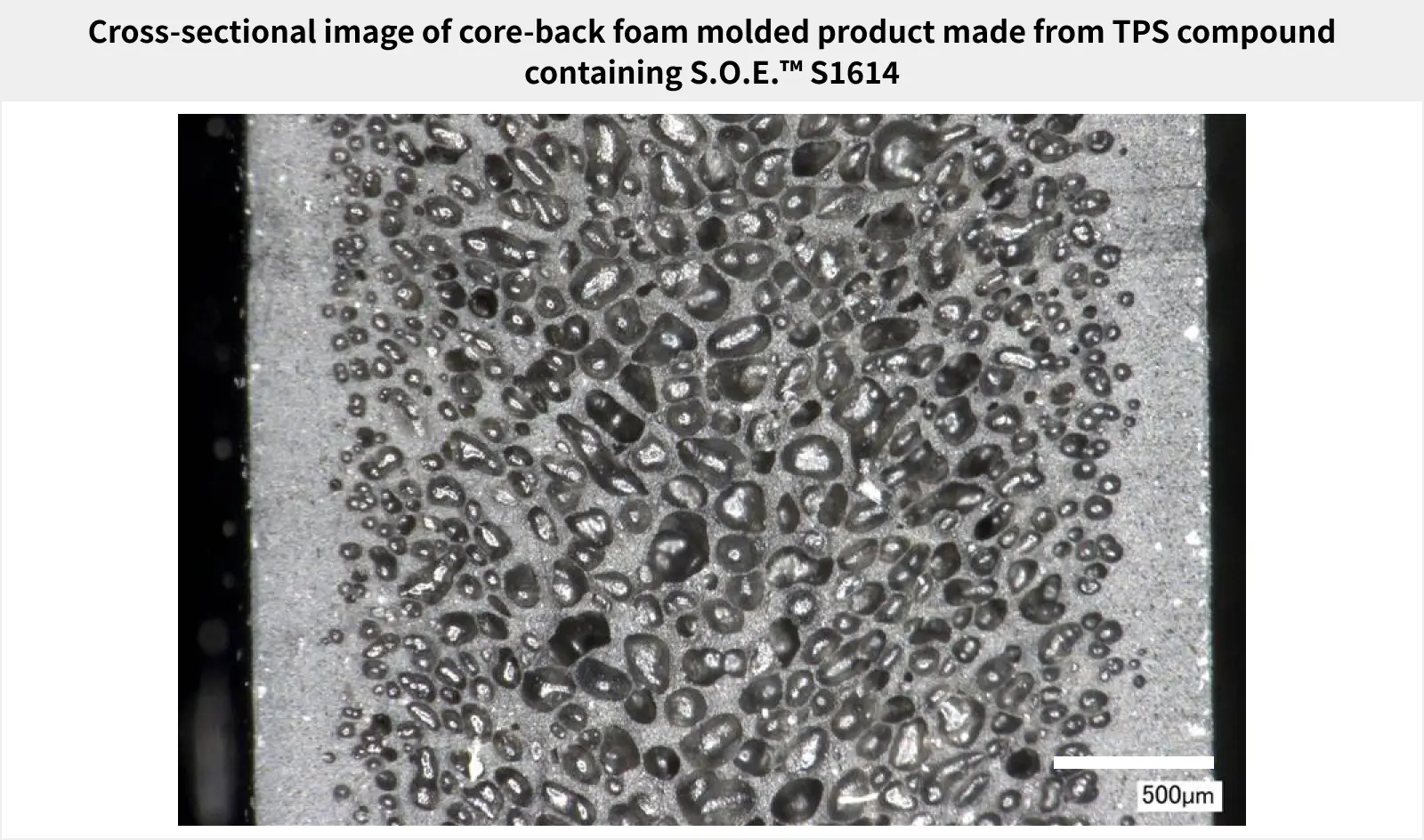

As a solution to this challenge, we propose "core back injection foaming molding by TPS compound containing S.O.E.™, which simultaneously molds the foam layer and the trim layer using only TPS compound. In this method, a TPS compound containing a chemical blowing agent and S.O.E.™ is filled into a mold, and then the mold is opened in the thickness direction to create foam cells. It has been confirmed that using a TPS compound containing S.O.E.™ S1614 allows for the molding of a good foam trim with closed cells.

Interior trim materials made of TPS compound alone eliminate the need of separation, as both the PP base substrate and elastomer layer are thermoplastic, unlike the combination of a urethane foam layer and an elastomeric trim layer. Simultaneous molding also offers the potential for cost reduction and CO2 reduction through process optimization.

Applications Using S.O.E.™ as a TPS Compound Raw Material

It can be used in various areas of automotive interior trim. In addition to automobiles, it can also be used in office chairs and other applications.