Asahi Kasei's SBS: Delivering Outstanding Low Temperature Performance and Processability

Asahi Kasei's styrene-based thermoplastic elastomers (SBS) TUFPRENE™ and ASAPRENE™ T are styrene-butadiene block copolymers. They excel in their rubber-like properties, compatibility with styrene-based resins and asphalt, and moldability. They are used in a wide range of applications such as food packaging materials, road paving materials, and sanitary adhesives.

TUFPRENE™・ASAPRENE™ T Details

TUFPRENE™ and ASAPRENE™ T Offer Superior Low-Temperature Properties and Processability

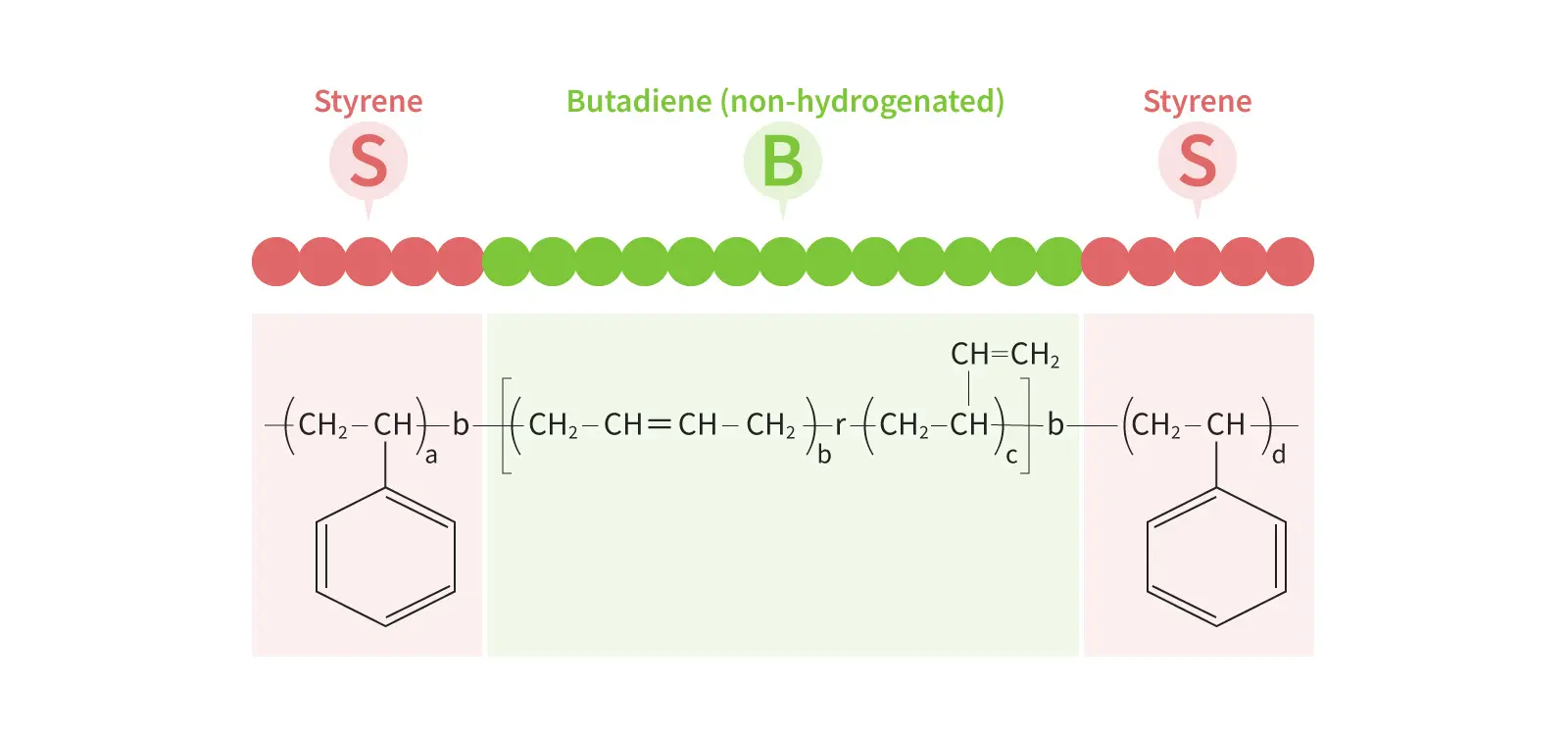

TUFPRENE™ and ASAPRENE™ T are styrene-based thermoplastic elastomers (SBS) consisting of polystyrene blocks and polybutadiene blocks. SBS is a block copolymer composed of polystyrene blocks as the hard segment and polybutadiene blocks as the soft segment. It exhibits rubber elasticity under low and room temperature conditions, while demonstrating flow characteristics similar to plastics under high processing temperatures. This unique material combines excellent performance and processability.

Key Features of TUFPRENE™ and ASAPRENE™ T

Rubber elasticity

Imparts impact resistance at low temperatures

Recyclable

High processability

Compatibility with PS-based resins and asphalt

Applications and Track Record of TUFPRENE™ and ASAPRENE™ T

Asphalt Modification Materials (Waterproof Sheets, Road Paving Materials)

Grade List of TUFPRENE™ and ASAPRENE™ T

| Measurement Conditions | Unit | TUFPRENE™ | ASAPRENE™ T | ||||||||

| A | 125 | 126S | T-411 | T-432 | T-437 | T-438 | T-439 | ||||

| Density | ISO 1183 | g/cm3 | 0.95 | 0.95 | 0.95 | 0.94 | 0.94 | 0.94 | 0.94 | 0.95 | |

| St/Bd Weight Ratio | - | Asahi Kasei Method | % | 40/60 | 40/60 | 40/60 | 30/70 | 30/70 | 30/70 | 35/65 | 45/55 |

| MFR | 190°C・ 2.16kg |

ISO 1133 | g/10 minutes | 2.6 | 4.5 | 4.5 | 0.0 | 0.0 | - | - | - |

| MFR | 200°C・ 5kg |

ISO 1133 | g/10 minutes | 13.0 | 20.0 | 20.0 | 0.0 | 0.2 | 2.0 | 25.0 | - |

| A Hardness | - | ISO 7619 | - | 85 | 88 | 91 | 75 | 75 | 75 | 80 | 83 |

| Tensile Strength | 300%Mo. | ISO 37 | MPa | 2.5 | 4.3 | 4.5 | 2.3 | 2.0 | 2.3 | 3.0 | 4.0 |

| 25% Toluene Melt Viscosity |

- | Asahi Kasei Method | mPa・s | 650 | 570 | 440 | 20,200 | 3,100 | 1,700 | 470 | 170 |

| 15% Toluene Melt Viscosity |

- | Asahi Kasei Method | mPa・s | - | - | - | - | 330 | - | 47.5 | 25 |

| 10% Toluene Melt Viscosity |

- | Asahi Kasei Method | mPa・s | - | - | - | 270 | - | - | - | - |

| tanδ Peak Temperature | - | °C | -80 | -78 | -88 | -83 | -87 | -86 | -90 | -87 | |

| Product Form | - | - | Pellets | Pellets | Pellets | Crumbs・ Powder |

Crumbs・ Powder |

Crumbs・ Powder |

Pellets | Pellets | |