Enhancing the functionality of food containers and packaging materials

Asahi Kasei's TUFTEC™ and TUFPRENE exhibit excellent compatibility with polystyrene (PS) and polypropylene (PP). As a modifier, they improve the low-temperature impact resistance of food containers and packaging materials. As a compatibilizer, they enhance recyclability and enable the use of bio-based materials.

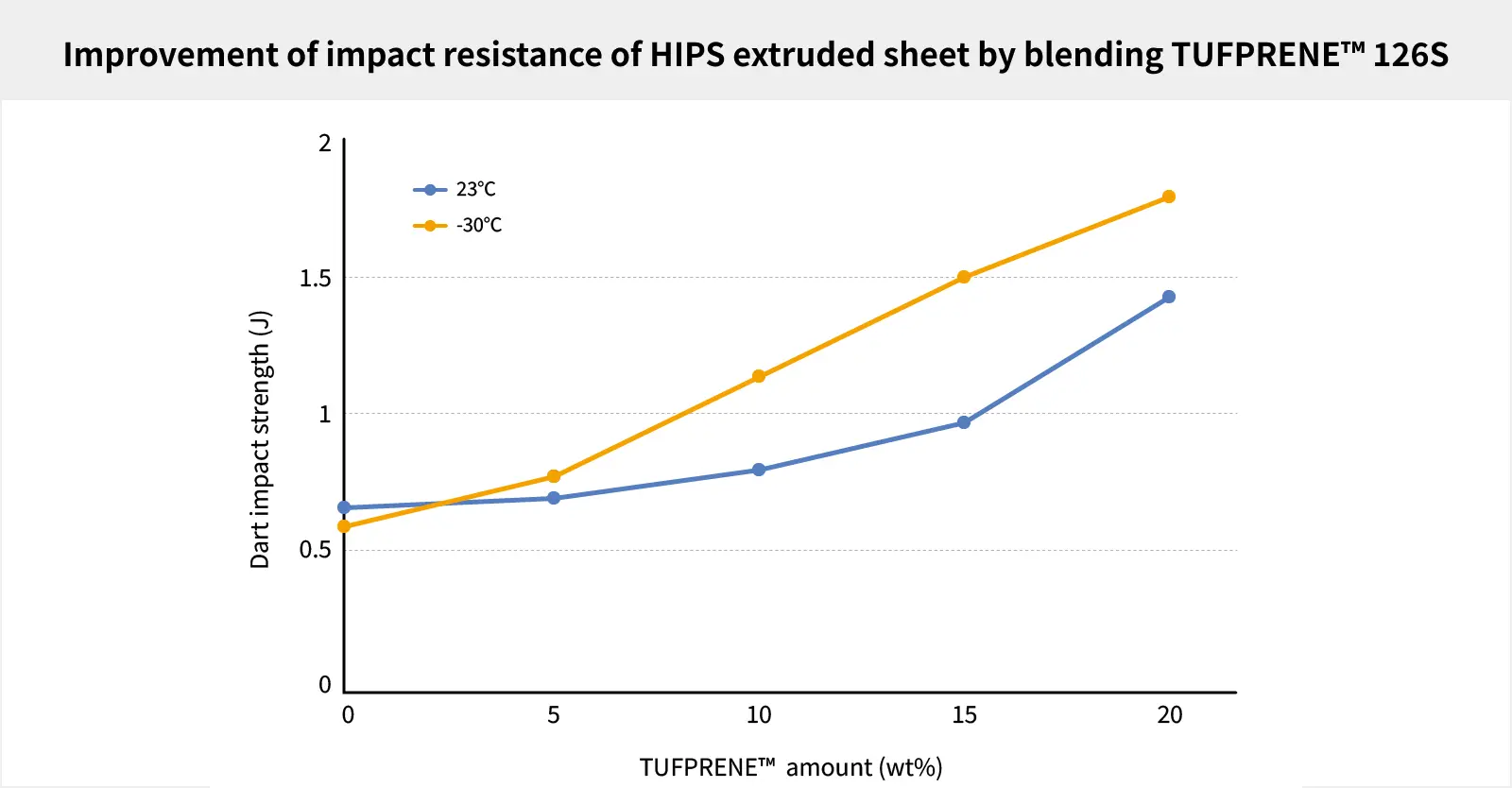

Improving Low-Temperature Impact Resistance of Food Packaging Materials and Food Containers

In the food industry, there is a growing demand for low-temperature storage and frozen foods to preserve freshness for extended periods. This has led to a challenge in improving the low-temperature impact resistance of food containers and packaging materials. Polystyrene (PS) and polypropylene (PP) are commonly used materials for food containers and packaging, but their impact resistance at low temperatures is limited. Using these materials alone poses challenges in maintaining quality and safety.

TUFTEC™ exhibits good compatibility with PP, while TUFPRENE™ exhibits good compatibility with PS. Both materials have a very low glass transition temperature (tanδ peak). Due to these properties, they can be added as modifiers to PS and PP, improving low-temperature impact resistance and contributing to the maintenance of food quality and safety.

TUFTEC™ and TUFPRENE™ offer various grades that comply with domestic and international food regulations, allowing for safe use.

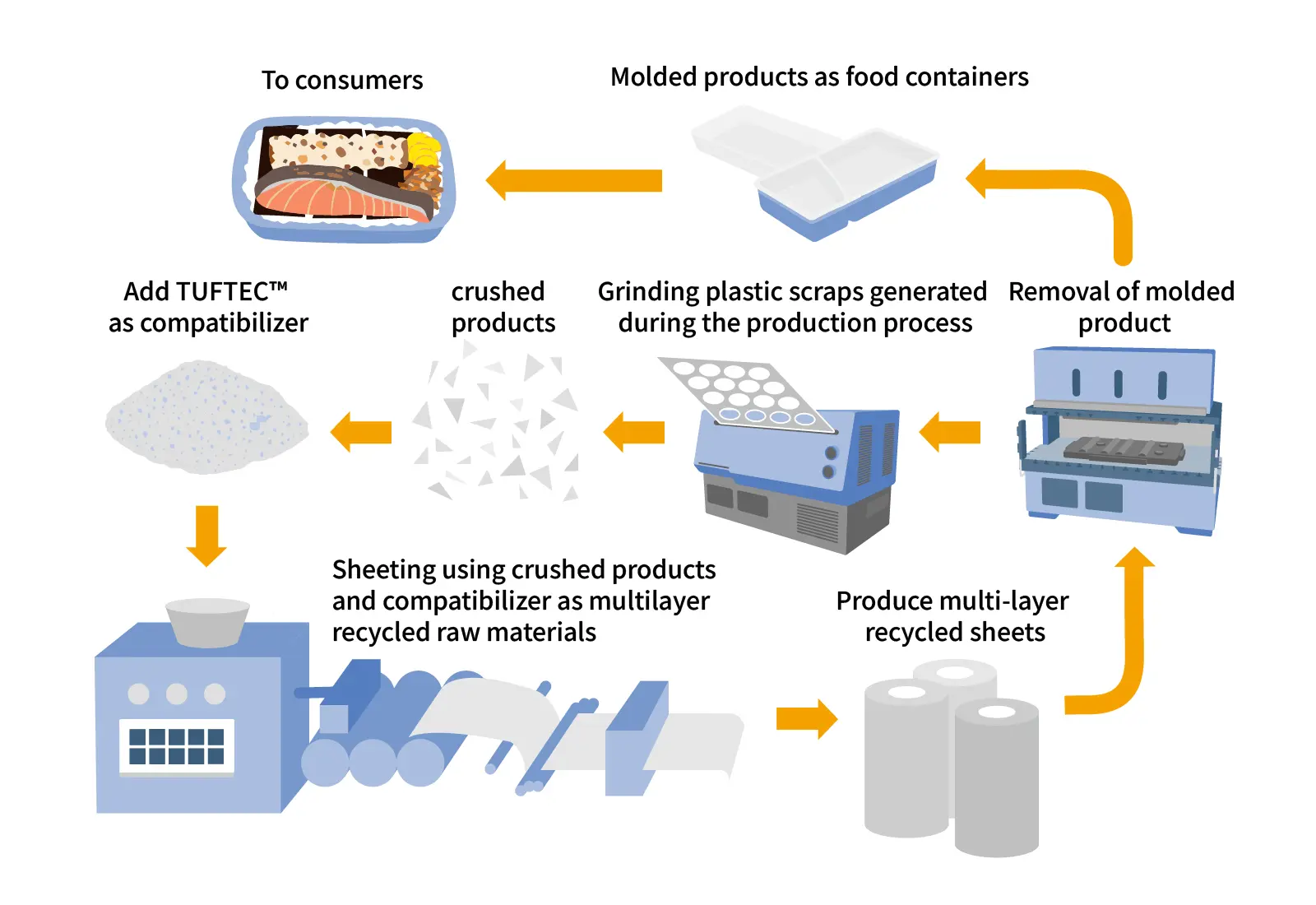

Plastic Scraps Recycling for Food Containers and Packaging Materials with TUFTEC™

The production of food containers and packaging materials often generates plastic scraps composed of composite materials. Recycling these scraps is often challenging, and effective recycling methods are urgently needed considering the environmental impact.

TUFTEC™ functions as a compatibilizer for a wide range of resins, enabling the recycling of these scraps containing different types of resins. This allows for the reuse of these scraps as raw materials, reducing waste.

Utilizing Biomass-Derived Materials with TUFTEC™

In the pursuit of environmental responsibility and sustainable resource utilization, the use of

biomass-derived materials is becoming increasingly important. Particularly in the field of food

containers and packaging materials, there is a demand for a wide range of properties while

considering sustainability. These properties include heat resistance for microwave use, oil

resistance to contain various food products, and the potential for diverse design possibilities.

TUFTEC™ consists of an ethylene-butylene backbone and a styrene backbone. It can be used as

a compatibilizer for olefin-based resins and styrene-based resins. Therefore, it is utilized as

a compatibilizer for olefin-based biomass plastics (e.g., bio-PE) and polystyrene (PS).

Additionally, TUFTEC™ M series, with its modified structure, enables the improvement of impact

resistance for polylactic acid (PLA), a highly polar material derived from biomass.