Achieve TPU Replacement with TPS Compounds Offering Superior Adhesion

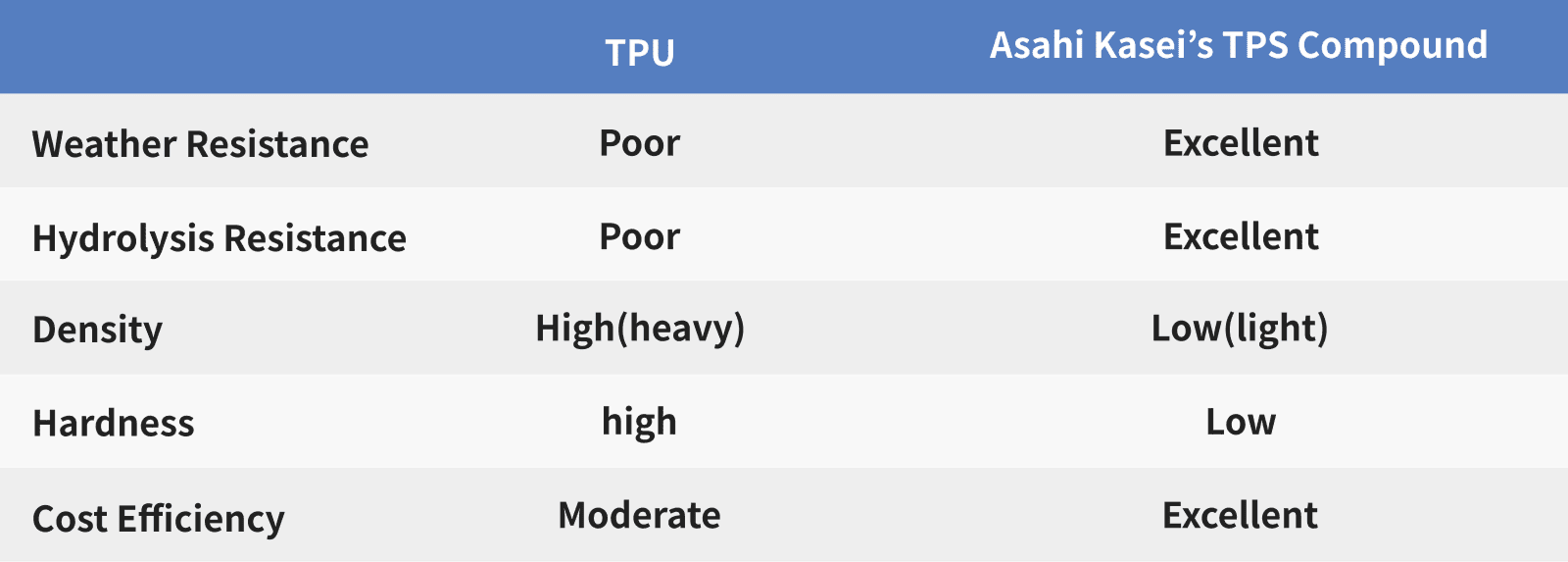

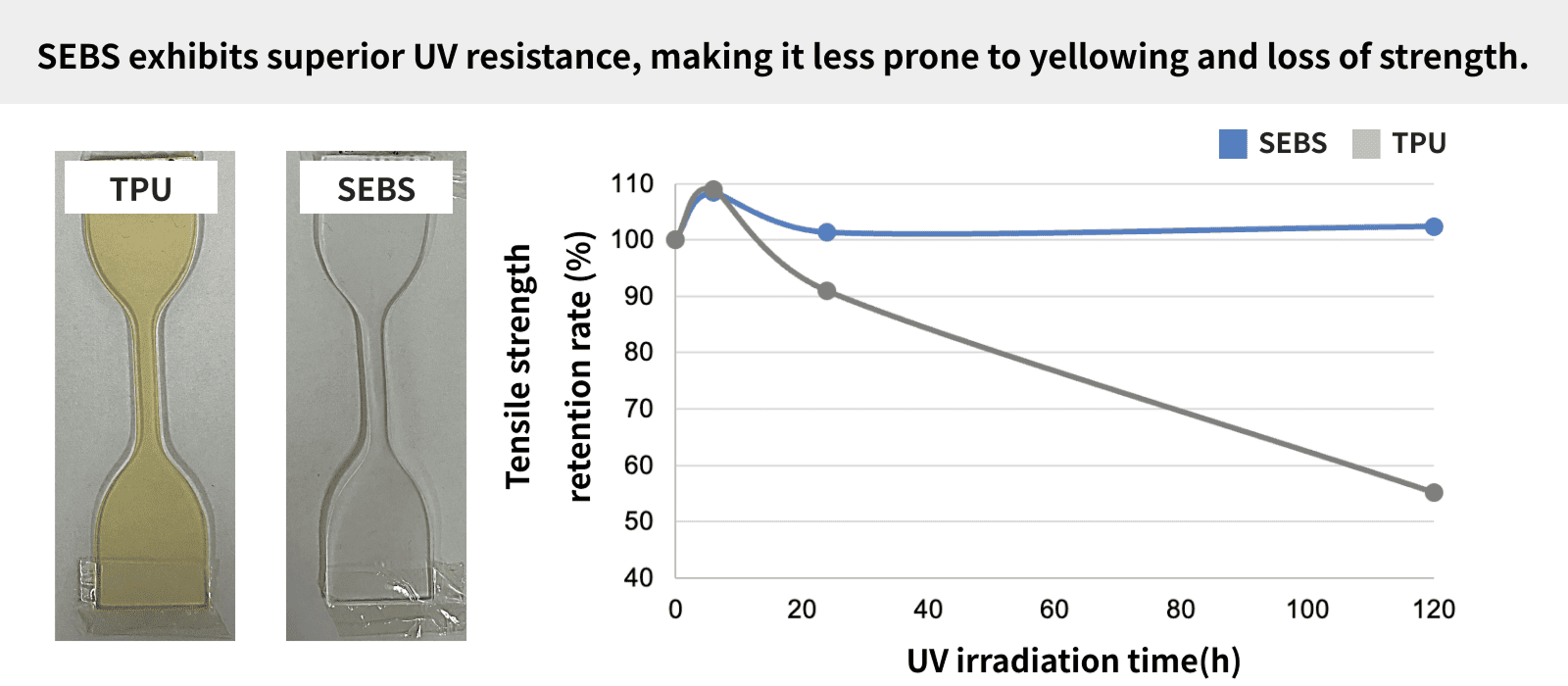

Conventional overmolding with TPU (Thermoplastic Polyurethane) has challenges such as yellowing from UV exposure and degradation, and increased weight due to high specific gravity. Asahi Kasei's SEBS is lighter than TPU, is highly resistant to yellowing, does not undergo hydrolysis, and offers excellent adhesion to substrates, resolving these issues as a TPU substitute.

Do you have these challenges in overmolding?

-

With TPU Compounds : Degradation and yellowing due to low UV / water resistance. Too hard and heavy molded parts by high specific gravity.

-

With TPS Compounds : Weak adhesion to polar substrates like PC and ABS.

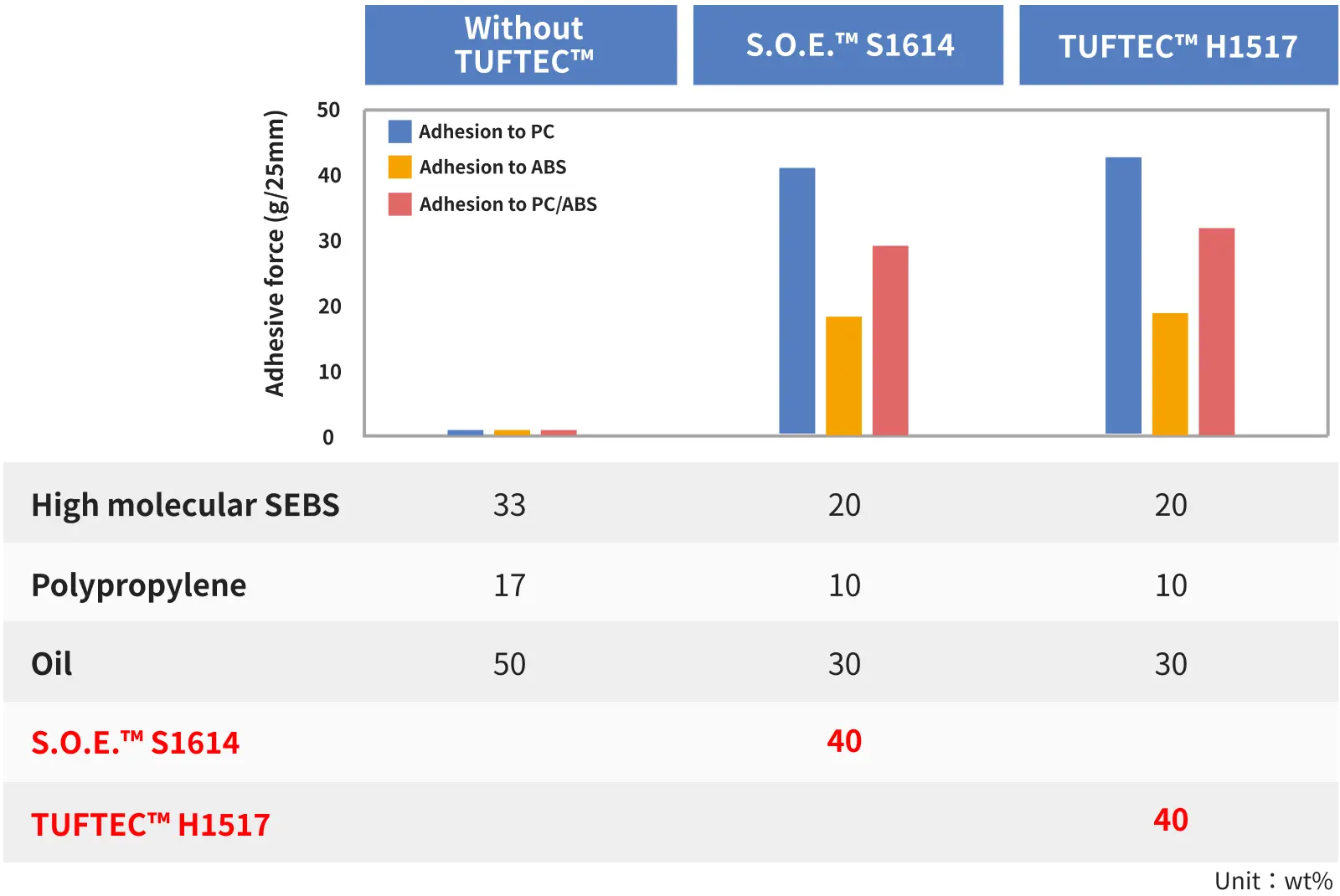

Asahi Kasei's TUFTEC™ H1517 and S.O.E.™ S1614 are styrenic thermoplastic elastomers (SEBS) that exhibit excellent thermal bonding and adhesion to high-polarity substrates such as polycarbonate (PC) and ABS resin. By incorporating them into compounds, you can solve the above challenges associated with both TPU and conventional TPS compounds.

Furthermore, by selecting the appropriate grade, we can meet more specific needs such as achieving transparency or improving processability with high flowability.

Improve UV/Water Resistance, Reduce Weight and Hardness as a TPU Alternative

In overmolding, TPU-based compounds are often used to enhance adhesion to polar resins like PC and ABS. However, these compounds have poor UV and water resistance, which can lead to degradation and yellowing due to hydrolysis.

Asahi Kasei's TUFTEC™ and S.O.E.™ are hydrogenated styrenic thermoplastic elastomers (SEBS) with excellent UV and water resistance. Using them as a substitute for TPU can resolve these problems. Additionally, they are lighter than TPU, allow for lower hardness, and may lead to cost savings depending on the compound formulation.

If you are interested in replacing TPU with TUFTEC™ and S.O.E.™, please contact us.

Excellent Adhesion to High-Polarity Substrates like PC and ABS

Common challenge with conventional TPS compounds in overmolding is poor compatibility with PC (Polycarbonate) and ABS resins, resulting in weak adhesion to the substrate.

TUFTEC™ and S.O.E.™, while being styrenic thermoplastic elastomers, feature a unique combination of a high butylene ratio and high styrene content. This enables excellent thermal bonding and adhesion even to high-polarity substrates like PC and ABS resins.

If you are interested in TPS compounds featuring TUFTEC™ and S.O.E.™, please contact us.

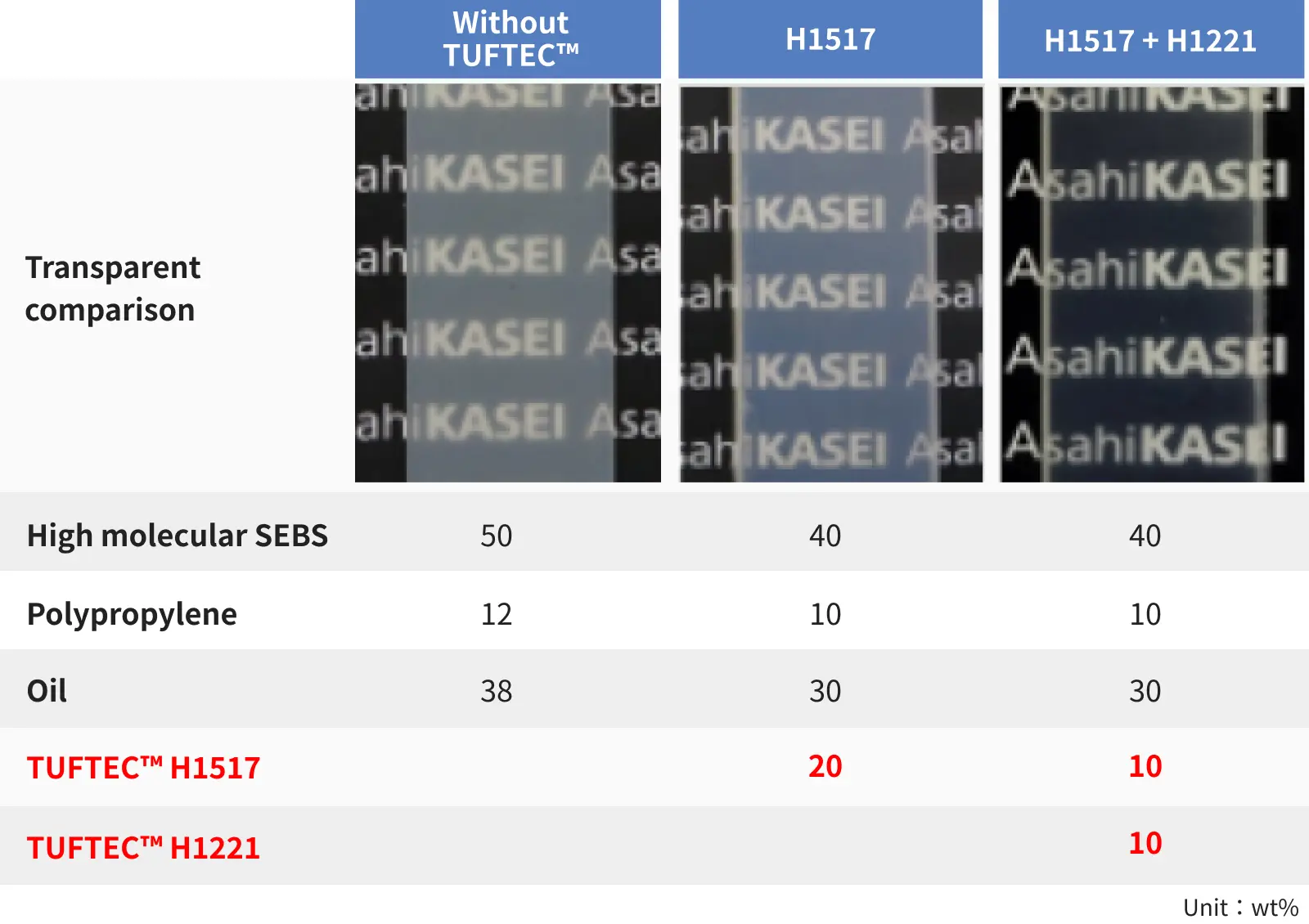

H1517 : Achieving "Transparent" Elastomer Compounds with High Design Appeal

Depending on the final product design, transparent overmolding may be required. In such cases, using elastomer compounds containing polypropylene (PP) can reduce the transparency of the molded part.

By using grades with good compatibility with PP, such as Asahi Kasei's TUFTEC™ H1517, as an additive, highly transparent molded products can be obtained even when PP is part of the formulation. Furthermore, TUFTEC™ H1517 maintains the significant benefit of high adhesion to the substrate.

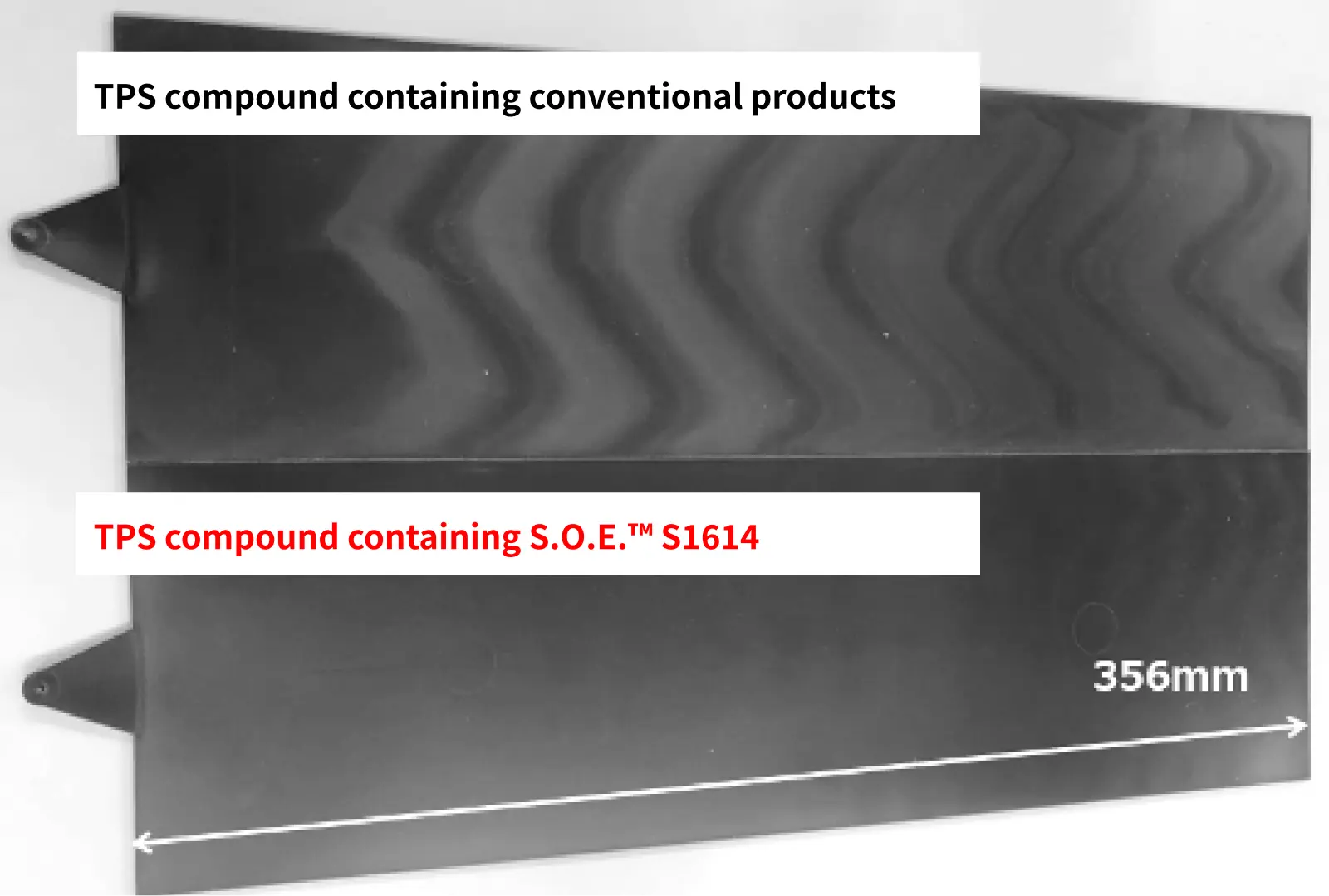

S1614 : Improved Processability with High Flowability for Excellent Appearance Quality

Low flowability of overmolding compounds can result in short shots and flow marks depending on the substrate shape.

S.O.E.™ S1614, with its high flowability, is an effective solution to such problems. By incorporating S1614 into the compound, a compound with excellent injection moldability and processability is obtained. This effectively suppresses the occurrence of short shots and flow marks.