We Continue to Pursue Sustainability Initiatives

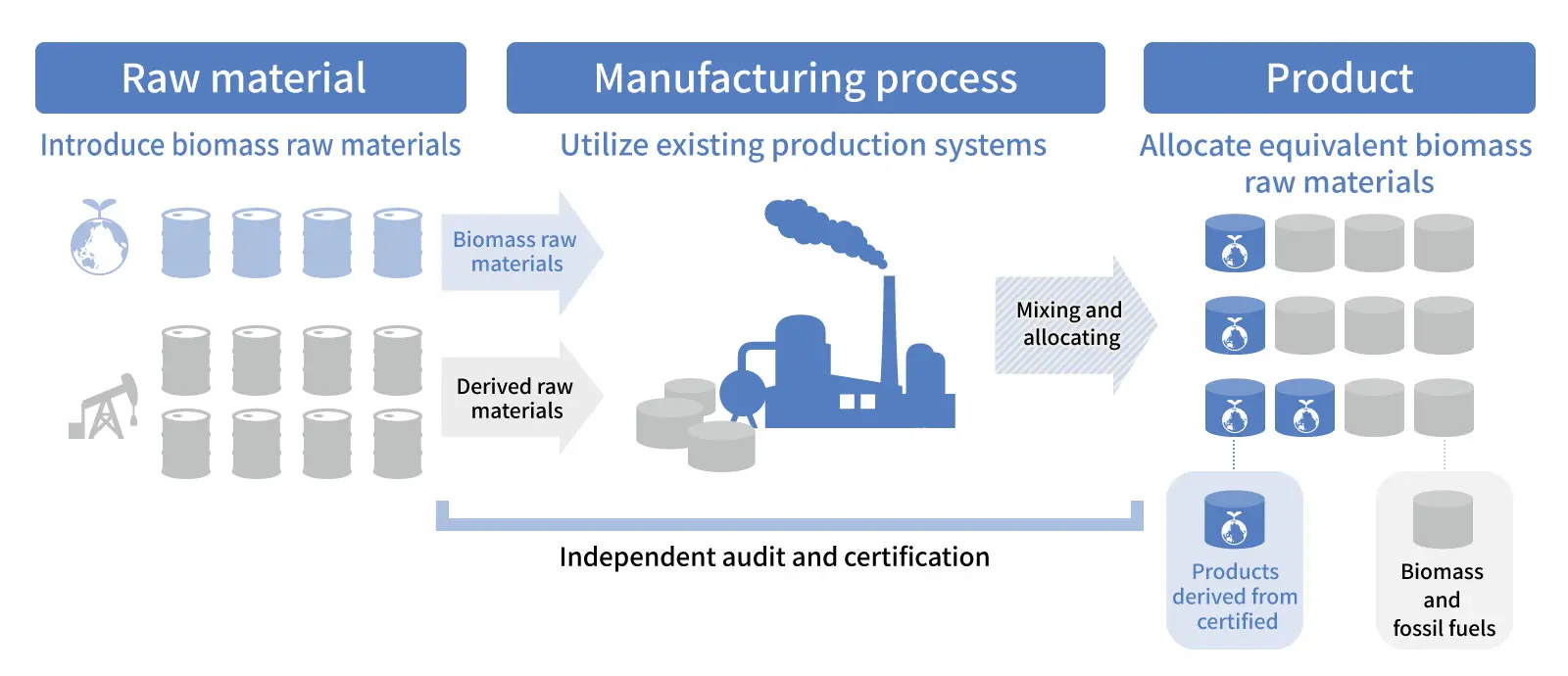

Asahi Kasei's elastomer business contributes to sustainability through initiatives such as the use of biomass-certified raw materials and carbon footprint visualization. In addition, elastomer products themselves contribute to the sustainability of various end products as modifier and compatibilizer materials.

Carbon Footprint Visualization of Elastomer Products

We have realized carbon footprint (CFP) visualization by utilizing a system developed in-house. This system reveals the CFP of each elastomer product and supports the calculation of CFP for customers' own products that incorporate those elastomers. We will promote CFP reduction activities throughout the entire supply chain, and ultimately throughout society, by providing CFP data and working together with our customers.

As CFP-related regulations such as carbon taxes become more widely adopted, it becomes increasingly important to understand the level of CFP data required for each regulation. Our system allows you to freely change the granularity (annual, monthly) and scope (average for all products, by product) of the CFP data being calculated, meeting the diverse needs of customers for elastomer products.

Elastomers Contribute to the Sustainability of End Products

Asahi Kasei elastomers can be used as resin modifier and compatibilizer materials, improving the performance of recycled plastics and biofiller compounds. This contributes to the sustainability of various end products.

-

Recycled PlasticsIn general, material recycling faces challenges such as "degradation of resin" due to long-term use and thermal history, and a decline in properties due to "mixed resins" that cannot be fully separated. TUFTEC™ can be used as a modifier and compatibilizer to improve the properties of recycled resin.

-

Biofiller CompoundsEfforts to reduce plastic usage by using high-fill biofillers are gaining attention as part of environmental measures. Biofiller compounds typically face the challenge of being weak in bending and impact, but using Asahi Kasei's TUFTEC™ as a compatibilizer allows for a more flexible compound.

-

Compatibility of Styrene Resins with Biomass PlasticsAsahi Kasei's TUFTEC™ can be used as a compatibilizer to allow for the blending of biopolyethylene (PE) with styrenic resins. This enables an increase in the biomass ratio of resin compositions without sacrificing mechanical properties such as impact resistance.

Learn more about "Compatibility of Styrene Resins with Biomass Plastics"