Widely used as a compatibilizer and modifier

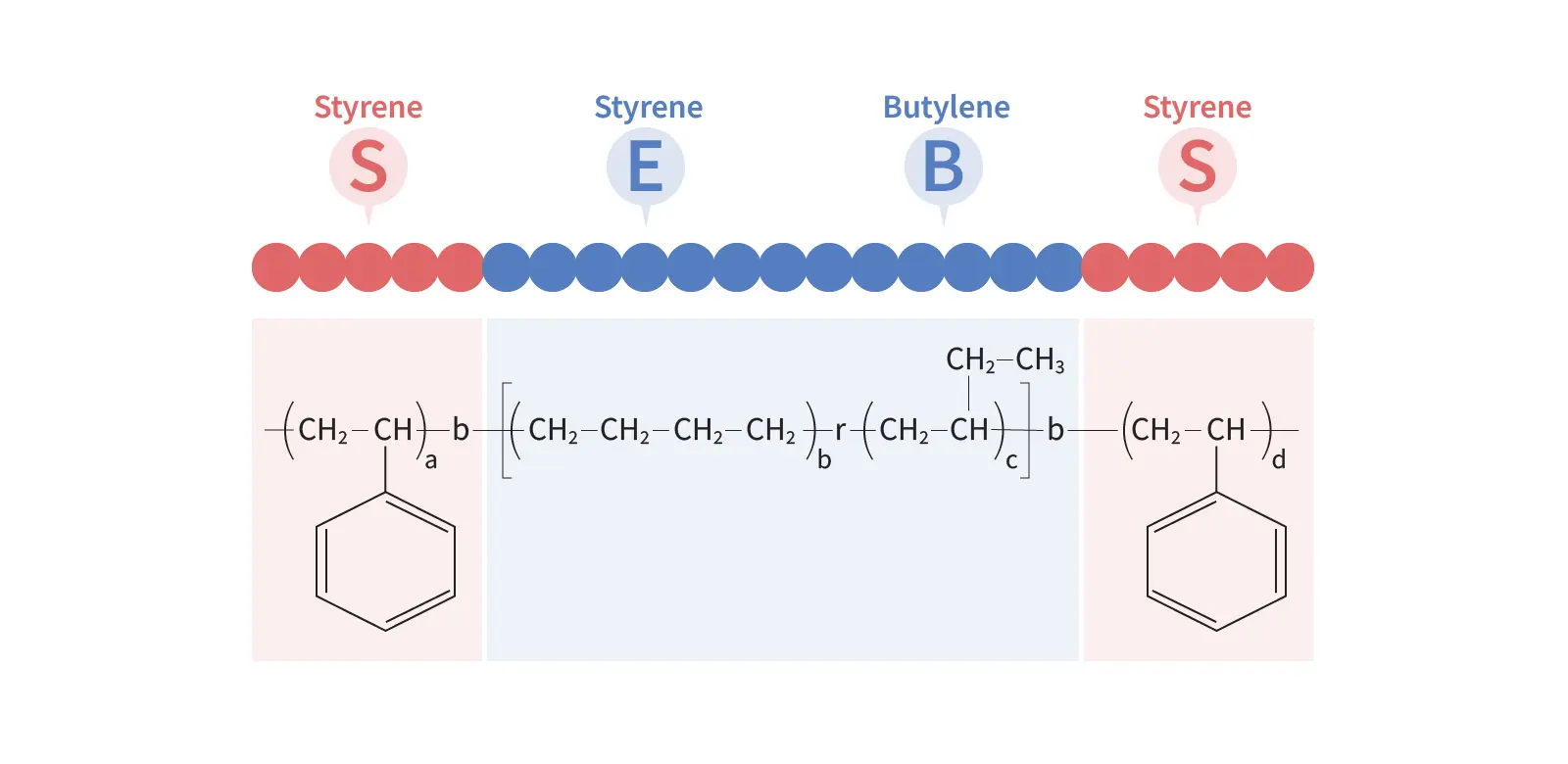

TUFTEC™ H series is a fully hydrogenated SEBS with excellent weather resistance and thermal stability. It is highly compatible with styrenic resins and olefinic resins and is widely used as a resin modifier, compatibilizer, and TPE compound raw material to enhance impact resistance and flexibility.

Details of TUFTEC™ H Series

Excellent weather resistance and thermal stability with a wide range of grades

TUFTEC™ H series is a SEBS in which the butadiene-derived soft block has been fully hydrogenated, resulting in exceptional weather resistance and thermal stability. The styrene-derived hard blocks aggregate at room temperature (below Tg), acting as pseudo-crosslinking points, while the hydrogenated butadiene soft blocks exhibit rubber elasticity. In particular, it is highly compatible with styrenic and olefinic resins and is used in a wide range of products to enhance impact resistance and flexibility.

Features of TUFTEC™ H Series

Rubber Elasticity

Provides impact resistance at low temperatures

Low dielectric properties

High Flexibility

Resistance to oxidative degradation and UV performance

Recyclable

Applications of TUFTEC™ H Series

Grade List of TUFTEC™ H Series

| Test Condition | Unit | H1524 | H1531 | H1221 | H1062 | H1521 | H1052 | H1053 | H1041 | H1522 | H1051 | H1517 | H1043 | N504 | H1272 | ||

| Density | ISO 1183 | g/cm3 | 0.89 | 0.89 | 0.90 | 0.92 | 0.91 | 0.89 | 0.91 | 0.94 | 0.92 | 0.93 | 0.95 | 0.98 | 0.91 | 0.90 | |

| Styrene | Asahi Kasei Method | wt% | 10 | 12 | 12 | 18 | 18 | 19 | 29 | 30 | 30 | 42 | 43 | 67 | 32 | 35 | |

| MFR | 230°C・ 2.16kg |

ISO 1133 | g/10min | 10.0 | 8.0 | 4.8 | 4.1 | 10.3 | 14.0 | 2.0 | 4.7 | 12.3 | 0.7 | 2.4 | 1.6 | No flow | No flow |

| A Hardness | 0s | ISO 7619 | - | 48 | 67 | 36 | 65 | 39 | 61 | 82 | 73 | 75 | >90 | >90 | >90 | - | 35 |

| 10s | 42 | 65 | 30 | 63 | 37 | 58 | 78 | 71 | 74 | >90 | >90 | >90 | - | - | |||

| D Hardness | 0s | ISO7619 | - | 39 | 39 | 67 | |||||||||||

| 10s | 40 | 38 | 64 | ||||||||||||||

| Tensile Properties | 100%Mo. | ISO 37 | MPa | 0.8 | 2.0 | 0.5 | 3.5 | 0.7 | 1.7 | 4.1 | 4.4 | 3.8 | 6.3 | 9.4 | Break | ||

| 200%Mo. | MPa | 1.0 | 2.6 | 0.7 | 4.1 | 1.0 | 2.2 | 5.0 | 5.3 | 4.9 | 7.0 | 9.5 | Break | ||||

| 300%Mo. | MPa | 1.1 | 3.2 | 0.8 | 5.0 | 1.3 | 2.9 | 6.8 | 6.8 | 6.6 | 9.7 | 9.5 | Break | ||||

| Tensile Strength | MPa | 6.4 | 12.0 | 11.2 | 13.1 | 13.5 | 13.0 | 32.3 | 29.7 | 14.2 | 29.0 | 13.1 | 35.6 | - | 18.6 | ||

| Elongation at Break | % | 940 | 622 | 1,100 | 720 | 890 | 644 | 570 | 604 | 590 | 524 | 600 | <100 | - | 950 | ||

| Melt Viscosity (200°C) |

122(1/s) | Asahi Kasei Method | Pa・s | 788 | 1,802 | 1,335 | 2,177 | 940 | 1,194 | 3,154 | 2,043 | 1,201 | 2,956 | 1,242 | 685 | ||

| 1.216(1/s) | 224 | 474 | 297 | 479 | 216 | 402 | 613 | 416 | 336 | 474 | 228 | 227 | |||||

| Melt Viscosity (230°C) |

122(1/s) | Asahi Kasei Method | Pa・s | 465 | 817 | 823 | 1,122 | 500 | 511 | 1,567 | 942 | 478 | 1,688 | 591 | 321 | ||

| 1.216(1/s) | 151 | 355 | 193 | 320 | 151 | 244 | 393 | 284 | 203 | 340 | 151 | 83 | |||||

| tanδ Peak Temperature | Torsion mode, 1Hz |

°C | -47 | -45 | -30 | -49 | -30 | -44 | -46 | -44 | -46 | -45 | -22 | -57 | - | - | |

| Refractive Index | JIS K 7142 | - | 1.49 | 1.49 | 1.50 | 1.50 | 1.50 | 1.50 | 1.51 | 1.51 | 1.51 | 1.52 | 1.53 | 1.55 | - | - | |

| Product Form | - | - | Pellets | Crumbs | Pellets (Oil-extended) |

||||||||||||