Achieve Compatibility with Polar Resins and Adhesion to Various Materials

TUFTEC™ M Series is a modified elastomer product with polar groups incorporated into the molecule. It exhibits high compatibility with various polar resins, making it suitable for use as a modifier or compatibilizer for engineering plastics. Furthermore, its excellent adhesion to metals and other materials allows for its use as an adhesive.

Details of TUFTEC™ M Series

Modification Contributes to Solving Challenges in Compatibility with Polar Resins and Adhesion to Various Materials, Including Metals

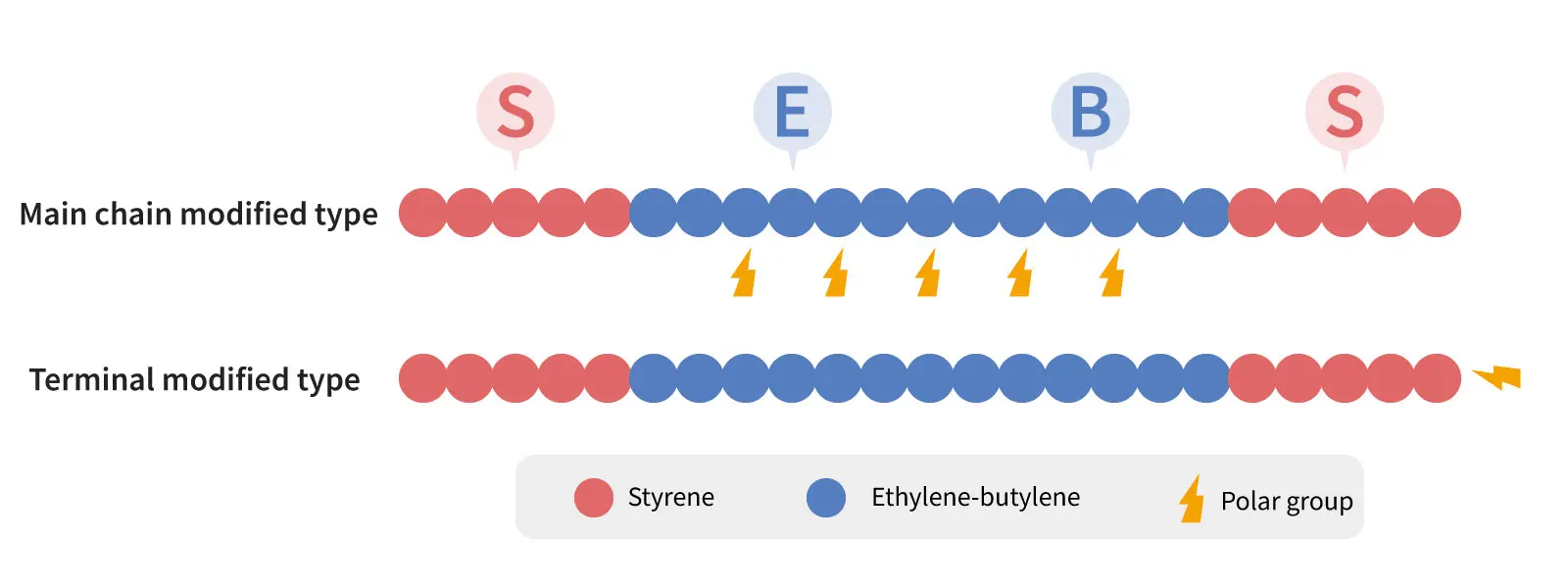

TUFTEC™ M Series is a product with polar groups incorporated into the SEBS molecule. Two types are available, depending on the location of the polar group introduction.

The main chain modified type has polar groups grafted onto the soft block, resulting in exceptional reactivity.

The end-modified type has limited reaction points, allowing for easy control of reactivity with the target material.

The introduction of polar groups enhances the excellent properties of the H and P series, providing increased reactivity with various polar resins and interaction with metal ions. It can be used as a modifier for engineering plastics, as an adhesive, and as a compatibilizer for non-polar and polar resins.

Features of TUFTEC™ M Series

Rubber Elasticity and High Flexibility

Imparts Impact Resistance at Low Temperatures

Dispersibility of Fillers

High Reactivity with Polar Resins

Resistance to Oxidative Degradation and UV Performance

Adhesion to Metals

Track Record of Applications for TUFTEC™ M Series

Grade List of TUFTEC™ M Series

| Measurement Conditions | Unit | M1943 | M1913 | M1911 | M1981 | MP10 | ||

| Modification | - | - | Maleic anhydride | Amine | ||||

| Addition Rate | Titration method | wt% | 1.8 | 1.8 | 0.4 | 0.7 | - | |

| Density | ISO 1183 | g/cm3 | 0.91 | 0.95 | 0.93 | 0.90 | 0.92 | |

| Styrene | Asahi Kasei method | wt% | 20 | 29 | 31 | 13 | 32 | |

| MFR | 230°C・ 2.16kg |

ISO 1133 | g/10 min | 6.5 | 6.5 | 4.2 | 7.2 | 4.6 |

| A Hardness | 0s | ISO 7619 | - | 65 | 82 | 76 | 37 | 90 |

| 10s | 62 | 77 | 74 | 27 | 86 | |||

| Tensile Properties | 100%Mo. | ISO 37 | MPa | 2.2 | 4.5 | 4.8 | 0.5 | 4.8 |

| 200%Mo. | MPa | 2.9 | 5.3 | 5.3 | 0.6 | 4.9 | ||

| 300%Mo. | MPa | 4.2 | 7.1 | 6.8 | 0.7 | 6.7 | ||

| Tensile Strength | MPa | 13.0 | 15.9 | 16.0 | 6.1 | 38.6 | ||

| Elongation at Break | % | 618 | 582 | 622 | 1,306 | 562 | ||

| Melt Viscosity (200°C) |

122(1/s) | Asahi Kasei method | Pa・s | 1,512 | 1,530 | 1,861 | 1,032 | 2,138 |

| 1.216(1/s) | 438 | 387 | 417 | 227 | 468 | |||

| Melt Viscosity (230°C) |

122(1/s) | Asahi Kasei method | Pa・s | 683 | 659 | 907 | 557 | 900 |

| 1.216(1/s) | 271 | 228 | 267 | 141 | 294 | |||

| tanδ Peak Temperature | Torsion mode, 1Hz |

°C | -43 | -43 | -47 | -29 | -52 | |

| Refractive Index | JIS K 7142 | - | 1.50 | 1.51 | 1.51 | 1.50 | 1.51 | |

| Product Form | - | - | Pellets | |||||