Flexible, strong, and with excellent elasticity, MEF™ is a moldable polyethylene foam which can be molded into a wide range of shapes.

With its excellent cushioning, flexibility, strength, and elasticity, polyethylene foam is widely used as a packaging material, industrial material, and also as a building material.

A feature is its use for a wide range of applications

Since the material is formed by shaping bead-shaped foam raw material in a mold, it is possible to create complex shapes in large quantities. Such products are used in a wide variety of applications, tailored to the needs of customers.

-

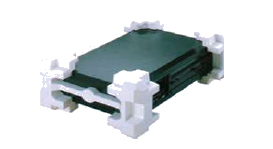

Cushioning, Returnable packaging

-

As a filling material for bedding

-

As a material for automotive parts

-

For sports products and miscellaneous goods

-

For industrial materials

Proposal of total solutions

- Reduced packaging size, one-way packaging, etc.

Physical properties

| Properties | Test Methods | unit | MEF™(Nominal value) | |||

|---|---|---|---|---|---|---|

| 10x |

15x | 30x | 40x | |||

| Compressive stress |

AK-FOAM Method (refer to JIS K 6767) 25%歪, 10mm/min |

kPa | 340 | 200 | 80 | 70 |

| Compression set |

AK-FOAM Method (refer to JIS K 6767) c.s. % (25%, 22h, 23℃) →24h after strain release |

% | 3 | 3 | 5 | 6 |

| Thermal conductivity |

AK-FOAM Method (refer to JIS A 1412-2) @ mean temp 0℃ |

W/(m・K) | 0.055 | 0.048 | 0.041 | 0.041 |

All values shown in this table are given as typical laboratory averages, intended to serve only as approximate guides and not as specifications.