Fabriform®

What is Fabriform®

The Fabriform process is a construction technique in which fluid mortar or concrete is pressure-injected into a fabric form made of high tenacity synthetic fiber. (Japanese Patent: 636074, 133167,706813)

The fabric form is water permeable, permitting the release of excess mixing water through the fabric under injection pressure.

Accordingly the resulting reduction of the water/cement ratio results in early stiffening of the concrete or mortar, increases in density and compressive strength,improvement in abrasion resistance and reduction of permeability.

The Fabriform process is applicable to construction of revetments for protecting the shorelines of canals, rivers,and reservoirs and also for preventing the scour of canal and stream beds.

Fabric casting is used in the construction of groins,breakwaters,pipeline saddles and similar oceanfront and deep water structure. Pile jacketing is for structural restoration and protection of steel,wood and concrete piles.

The Fabriform process is described in U.S. and foreign patents assigned to Construction Techniques,Inc. (Contech) and is offered in Japan under exclusive license by Asahi Chemical's Industry Co.,Ltd. which provides marketing and technical services.

The fabric is woven of Asahi Chemicals high tenacity synthetic fiber which is particularly suitable for use in the Fabriform process. Experience record to date has been excellent.

The Fabriform revetment or mat is a double layer fabric form woven of high tenacity synthetic fiber yarn necessary to sustain injection pressure. Textured yarn improves filtering characteristics of the fabric and prevents loss of cement. Fabriform structures can be installed in-the-dry and underwater with equal facility.

Advantage of Fabriform®

1. High production:

Fluid mortar is pump injected. Large surface area can be quickly protected.

2. Conforms perfectly to the ground surface:

Fabriform adapts to curved and irregular surfaces. The thickness on the revetment will be uniform regardless of slope or gradient.

3. Fabric forms are shop assembled:

Fabric assemblies are tailored in the shop to suit site topography. Shop assembly saves man hours in the field,providing cost savings over conventional methods.

4. Economical transport and storage:

Transportation and storage of fabric forms are easy and safe because of its light weight (450-500 g/m2 ),strength and durability.

5. High strength and rapid stiffening:

Since the W/C ratio of the mortar is greatly reduced during pressure injection,stiffening is rapid,early compressive strength is very high and curing time is greatly reduced.

6. Easly installed underwater:

No dewatering is necessary. Fabriform can be installed even under flowing water. There is no need to reroute a river or canal. Fabriform saves time and money.

Main types of Fabriform®

Fabriform® construction photos by application

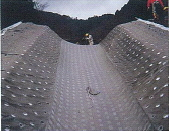

Dam flooded surface frame work (CP100M)

Dam slope protection work (FP150RJ)

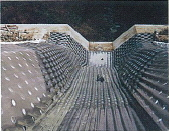

Fishway protection work (CX type)

Regulation pond (NF + greening type KH type)

River bank protection work (FP150)

Port underwater construction (CX type)

Channel work (NF + greening type GP type)

Channel work (NF100)

Channel work (CX200)

Types of Mats

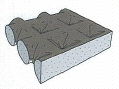

| Filter Point Mats (FP) | |

|---|---|

|

Two layers of fabric are woven together at regularly |

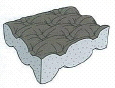

| Non-Filter(NF)Mat | |

|

Two layers of fabric are laced together by drop stitches |

| Concrete Mat(CX)=Storm Mat | |

|

CX fabric is used for constructing concrete slabs. |

| Revetment Greenification (GP) Mat | |

|

Two fabric layers are woven together to a single layer is |

Type of mats and typical use

| Name of mat | Thickness |

Injection |

Use | |

|---|---|---|---|---|

| Filter Point | FP65 | 6.5 | Mortar | Temporary erosion protection |

| FP100 | 10 | Erosion and scour protection: slope, |

||

| FP150 | 15 | |||

| Non Filter | NF50 | 5 | Mortar | Irrigation channel, reservoir, pond Erosion and scour protection |

| NF100 | 10 | |||

| NF150 | 15 | |||

| Concrete Mat | CX200 | 20 | Concrete | Erosion and scour protection for hard condition: embankment of big river wave action at seaside under jetty dock |

| CX250 | 25 | |||

| CX300 | 30 | |||

| CX350 | 35 | |||

| CX400 | 40 | |||

| CX500 | 50 | |||

| CX700 | 70 | |||

| Revetment

|

GP50 | 5 | Mortar | Vegetation and protection of aquaducts in mountains, |

| GP65 | 6.5 | |||

| GP100 | 10 | |||

| GP150 | 15 | |||

- Above mentioned thickness is average thickness of the mattress.

- If required, weep hole can be set to NF and CX type within one hour after injection.

Constructions

RESERVOIR·CONTROL POND·FISH POND

Retention pond

three-sided waterway

VEGETATING REVETMENT

HARBOR·UNDERWATER

Typical Composition of injection mortar and concrete

| Cement/Sand ratio C : S |

Water/Cement ratio W/C (%) |

Cement unitquantity (kg/m3) |

flow. (sec.) |

note |

|---|---|---|---|---|

| 1 : 2 | 55~65 | 600 | 18土3 | ・chemical admixture ・AE agent ・water reducing agent |

【Reference】

| Cement/Sand ratio C : S |

Water/Cement ratio W/C (%) |

unitquantity(kg/m3) | flow. (sec.) |

note | ||

|---|---|---|---|---|---|---|

| cement | sand | water | ||||

| C | S | W | ||||

| 1:2 | 60 | 600 | 1,200 | 360 | 18土3 | ・chemical admixture ・AE agent ・water reducing agent |

CONCRETE

| max. size of coarse aggregate (mm) |

water/ cement ratio W/C (%) |

percentage of sand s/a (%) |

Cement unit quantity (kg/m3) |

range of slump (cm) |

note |

|---|---|---|---|---|---|

| 20~25 | 55~65 | 50~60 | 370 | 22土3 | ・chemical admixture ・AE agent ・water reducing agent |

【Reference】

| max. size of coarse aggregate (mm) |

water/ cement ratio W/C (%) |

percentage of sand s/a (%) |

unit quantity(kg/m3) | range of slump (cm) |

note | |||

|---|---|---|---|---|---|---|---|---|

| cement | sand | coarse aggregate |

water | |||||

| C | S | G | W | |||||

| 25 | 65 | 50 | 370 | 775 | 785 | 240 | 22土3 | ・chemical admixture ・AE agent ・water reducing agent |

Standard Installation Procedure

1. Slope preparation

Check the dimension of the mattresses assembled to be sure that they conform to the surveyed drawing. Remove the obstacles which may damage the mattress such as sharp stones,vegetation and stumps etc.

Finish the surface to be even.

Maximum gradient 45°

If the toe of the slope is 50 cm or more underwater, velocity flow should be reduced to less than 1.5m/sec.Upper anchor trench: Excavate a trench (depth about 50 cm)at a point 50 cm away from the top of the slope.

Lower toe trench: For river bank protection,excavate a trench(depth 1.0 to 1.5m) at the toe of the slope.

Flank trenches at both sides: Excavate flank trenches(depth about 1.0m)at both upstream and downstream ends of the installation,whether or not extension of the revetment is anticipated. The design of anchor,toe and flank trenches are determined according to the nature of the soil, hydraulic considerations and site conditions.

2. Placement of the mat

For installation in-the-dry, start by placing the mat over the lower part of the slope at the downstream end of the structure. For underwater installation, start mattress placement from the upstream end of the installation.

Starting from the toe of the slope,spread the mattress over the entire slope,taking up slack at the top of the slope where the mat is positioned with chain hoists and pipes.

3. Injection of mortar or concrete

Start injection of mortar or concrete through the injection mouth at the lowest point of the mat.

After starting injection,please handle the chain hoist to adjust the slack of the mattress in accordance with the progress of injection. When the mortar or concrete is sufficiently injected into the top of the mattress,stop the injection work and bind the rope at the injection mouth.

Capacity of mortar or concrete injection pump: 10m3/hr. or more

Pressure at the nozzle: about2kg/cm2.

Piping hose(swing type):about diam.:50mm,about length: 20m.

(Position the pumping truck to assure minimum hose length for maximum operating efficiency.)

Choke(taper)tube: about diam.:10cm-5cm,length: about 2m with joint at both ends.

4. Completion

Finishing

Sprinkling(washing,curing)the surface with water. Filling the space between mat and existing structure with stiff consistency concrete.

Back-filling with sand,soil,cobble stone, toe protection block,etc.Curing