M Series: The Optimal Choice for Improving PA Impact Resistance

TUFTEC™ M Series, a modified SEBS, can impart impact resistance and flexibility to polyamide by being finely dispersed within the material. It also helps to reduce the water absorption of polyamide and improves toughness.

Detailed Information on Grades Suitable for Polyamide (PA) Modification

Grades Optimal for Improving Polyamide Impact Resistance

TUFTEC™ M Series offers four recommended grades based on differences in styrene content.

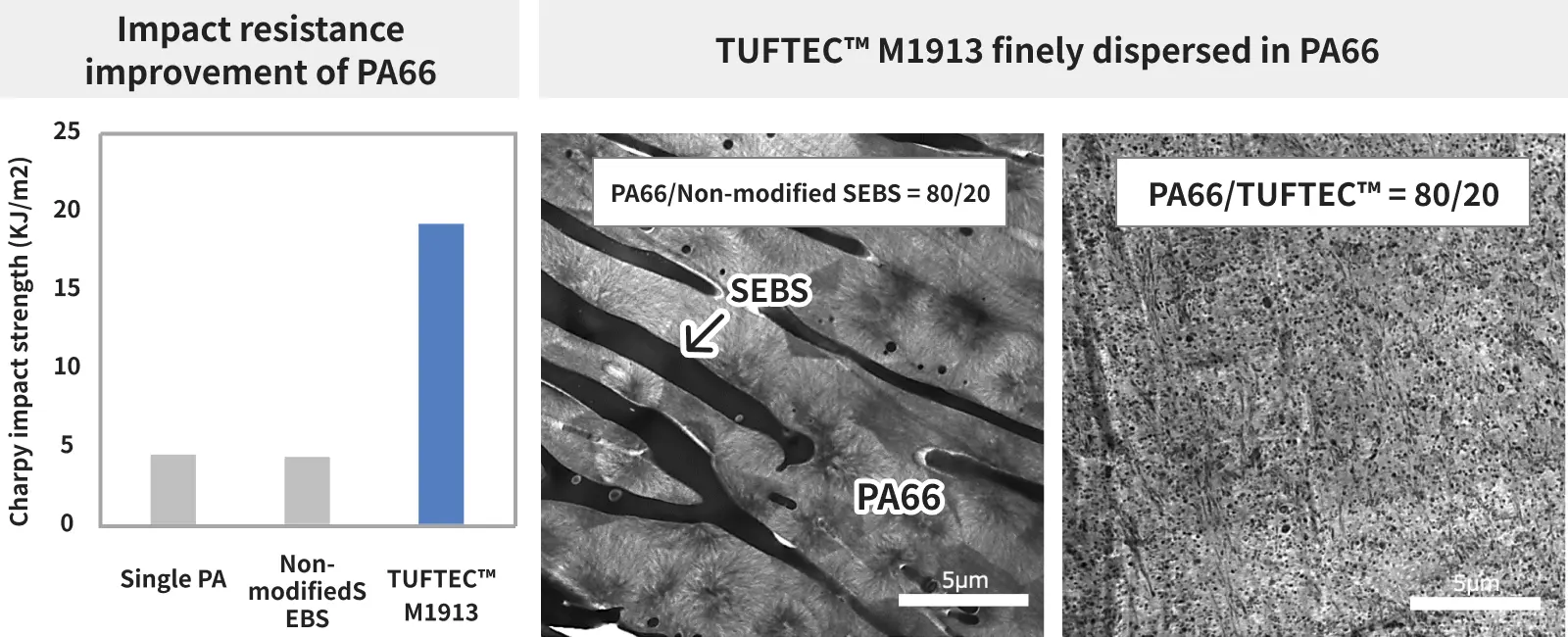

Impact Resistance and Flexibility Improvement with TUFTEC™ M Series

Polyamide boasts excellent mechanical strength, heat resistance, and chemical resistance, making it a widely used injection molding material for automotive parts, industrial components, and home appliances. However, it faces challenges with impact resistance at low temperatures and the effect of moisture absorption on mechanical properties.

TUFTEC™ M Series is a modified SEBS. The maleic anhydride grafted to the SEBS backbone reacts with the polyamide, causing the modified SEBS to be finely dispersed within the polyamide. This imparts impact resistance and flexibility.

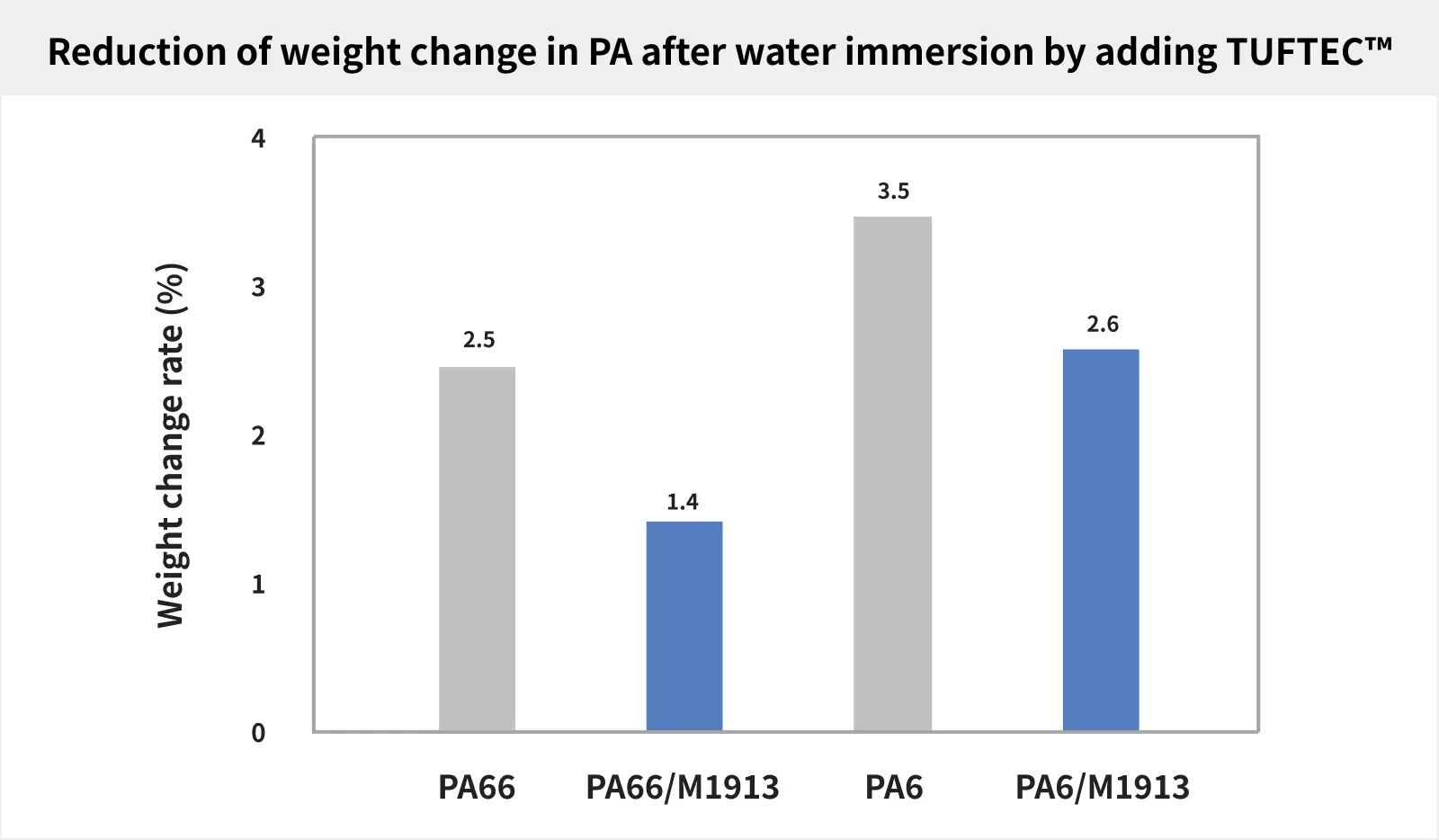

TUFTEC™ M Series Enables Suppressed Water Absorption in PA

Polyamide (PA) likely has the problem that its mechanical properties are easily affected by moisture absorption. By adding TUFTEC™ M1913, we can impart excellent water resistance to polyamide. Polyamide with TUFTEC™ M1913 shows a lower weight change rate when immersed in water compared to unmodified polyamide (see figure below).