TUFTEC™ - Ideal for PP Modification

Asahi Kasei's TUFTEC™ can be used as a modifier for polypropylene (PP). This page provides information on the optimal grades for three PP modification applications: “flexibility and transparency,” “impact resistance improvement,” and “heat sealability.”

Functions for Polypropylene (PP) Modification with TUFTEC™

Grades Suitable for PP Flexibility and Transparency Enhancement

TUFTEC™ offers three recommended grades for flexibility and transparency enhancement, depending on the desired degree of flexibility, transparency, and other properties.

Mechanism of Flexibility and Transparency Enhancement with TUFTEC™

Polypropylene (PP) has a glass transition point near 0°C, leading to challenges such as embrittlement at low temperatures and reduced transparency due to light scattering caused by crystalline particles.

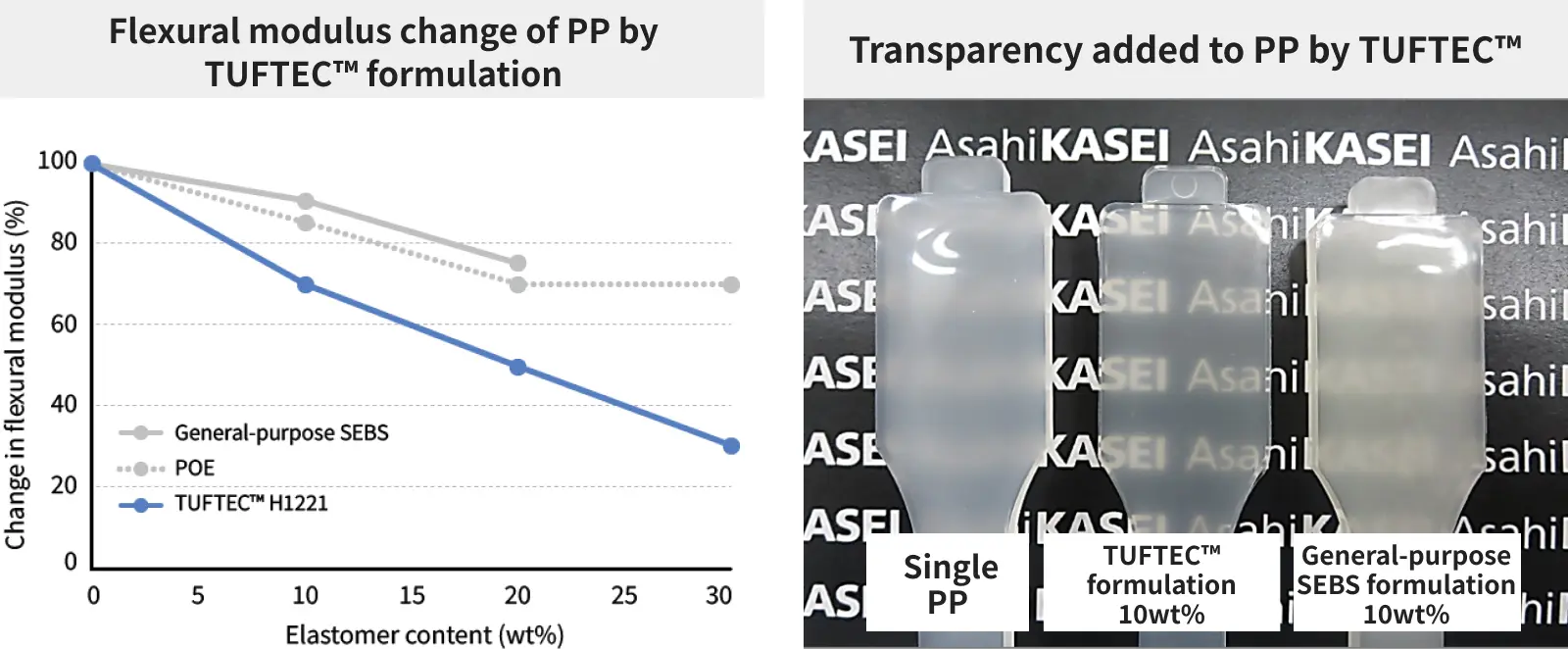

TUFTEC™ addresses these issues. Adding TUFTEC™ TUFTEC™ reduces the flexural modulus of PP, enabling great flexibility. Compared to olefinic elastomers (POE) and general-purpose SEBS, the effect of TUFTEC™ is particularly remarkable (see figure below).

Furthermore, TUFTEC™ enhances transparency of PP products. TUFTEC™ designed for PP modification exhibits exceptional compatibility with PP, effectively inhibiting crystallization through uniform dispersion. This significantly improves the transparency of PP products (see figure below).

Grades Suitable for PP Impact Resistance Improvement

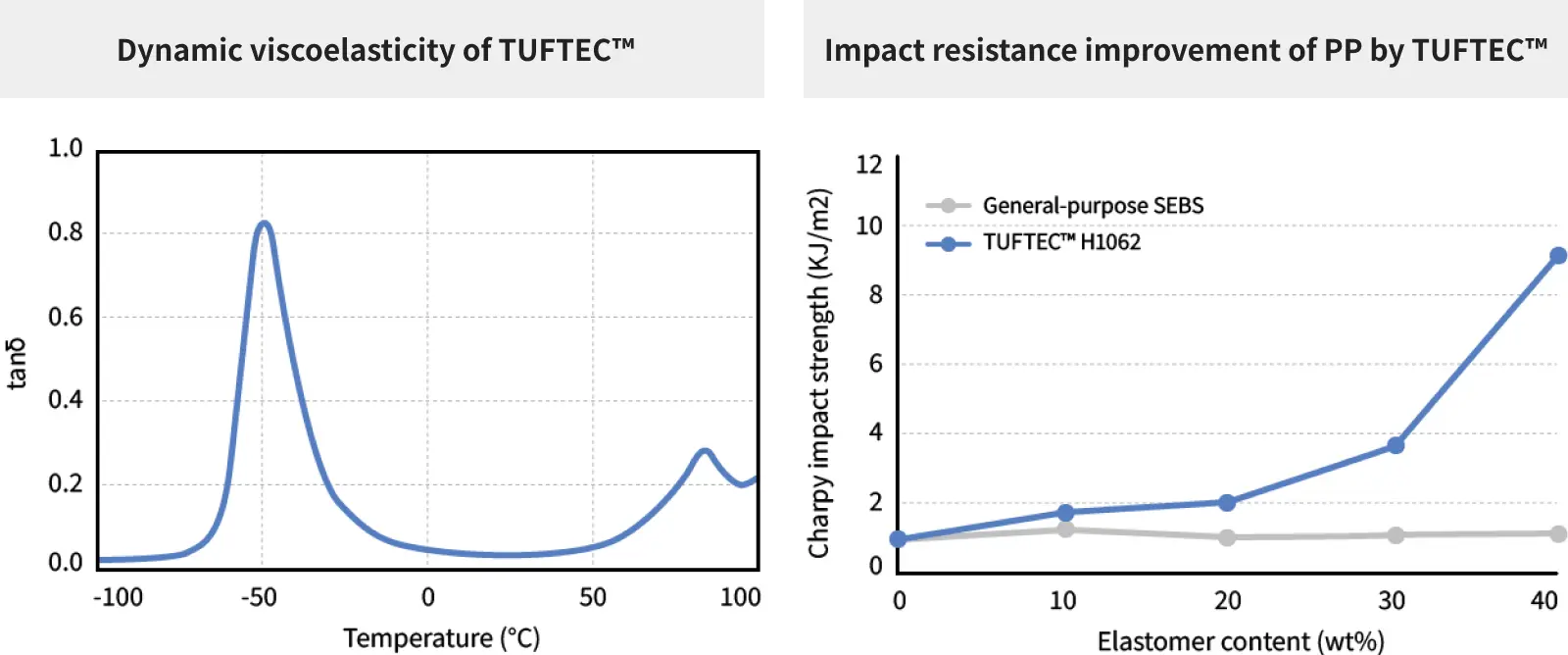

Reason for PP Impact Resistance Improvement with TUFTEC™

Polypropylene (PP) has a glass transition point around 0°C, making it susceptible to embrittlement at low temperatures.

-

TUFTEC™ H1062:With tanδ peak around -50℃ (glass transition point is -50℃) enables to impart excellent low-temperature impact resistance in polypropylene. Moreover, the butadiene-derived soft block is fully hydrogenated, ensuring excellent weatherability and heat aging resistance.

Grades Suitable for Imparting Heat Sealability to PP

TUFTEC™ offers three recommended grades for heat sealability enhancement, based on the desired heat seal strength.

Why TUFTEC™ Enables Heat Sealability Enhancement for PP

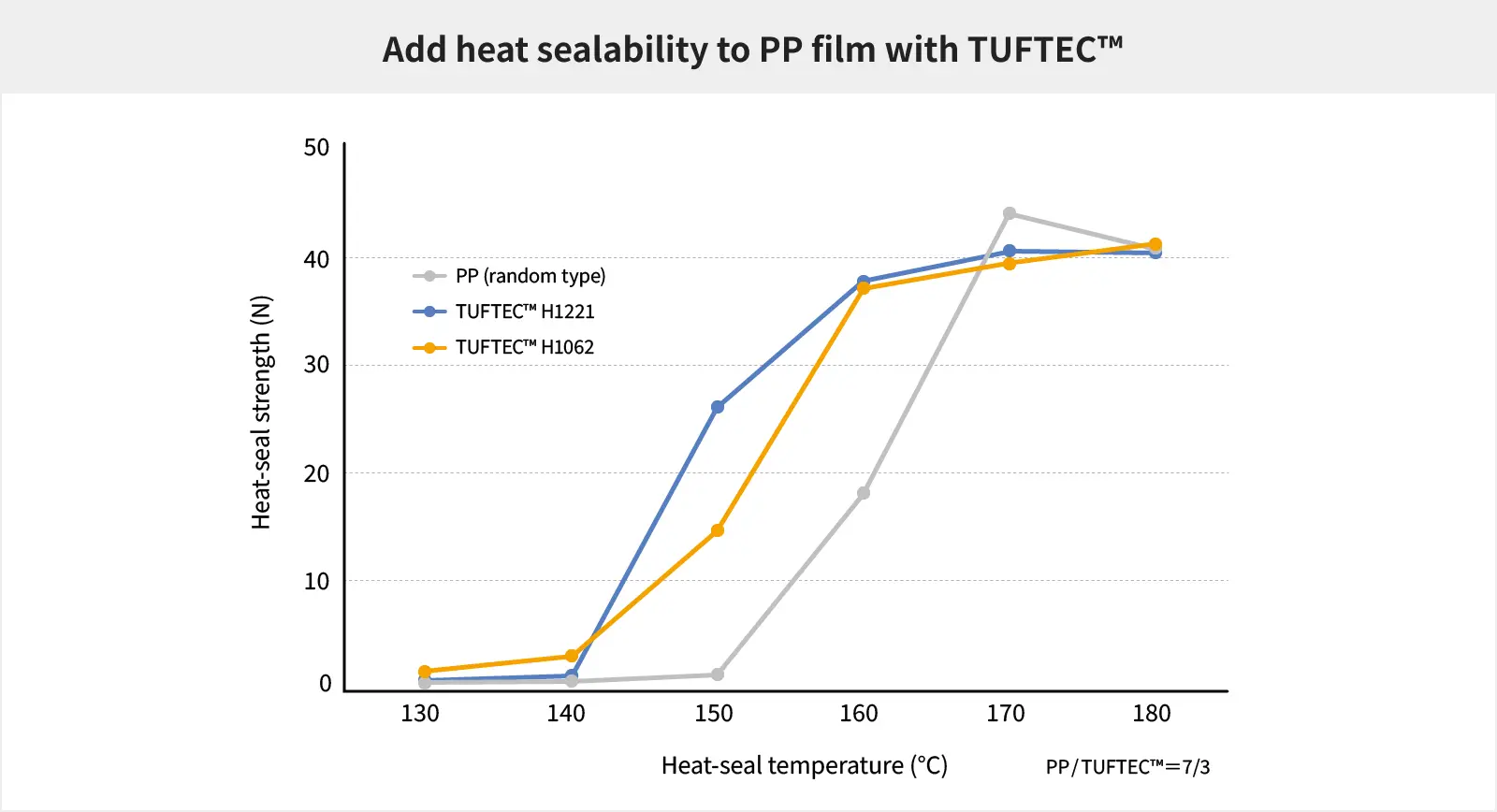

Blending TUFTEC™ with polypropylene (PP) imparts heat sealability. The heat sealability of TUFTEC™ varies depending on the grade and blend ratio. It can be classified into Type A and Type B, imparting different seal strengths. By combining Type A and Type B TUFTEC™ in the sealant layer and adjusting the blend ratio, heat seal strength can be customized.

-

Type A (H1221)Exhibits high heat seal strength at 150℃. The seal curve rises sharply, resulting in films with high sealability.

-

Type B (H1062)Exhibits weak seal strength around 150℃. The seal curve rises gradually, allowing for easy control of seal strength by adjusting the heat seal temperature.