Achieving Polymer Alloys with Superior Mechanical Properties

By using TUFTEC™ as a compatibilizer, it is possible to reinforce the PP/PS interface and achieve a polymer alloy with superior mechanical properties. This page explains the excellent compatibilizing mechanism of TUFTEC&trage; and optimal grades based on the styrene content in polymer alloys.

Detailed Information on Grades Suitable for Compatibilizing "Styrenic Resins × Olefinic Resins"

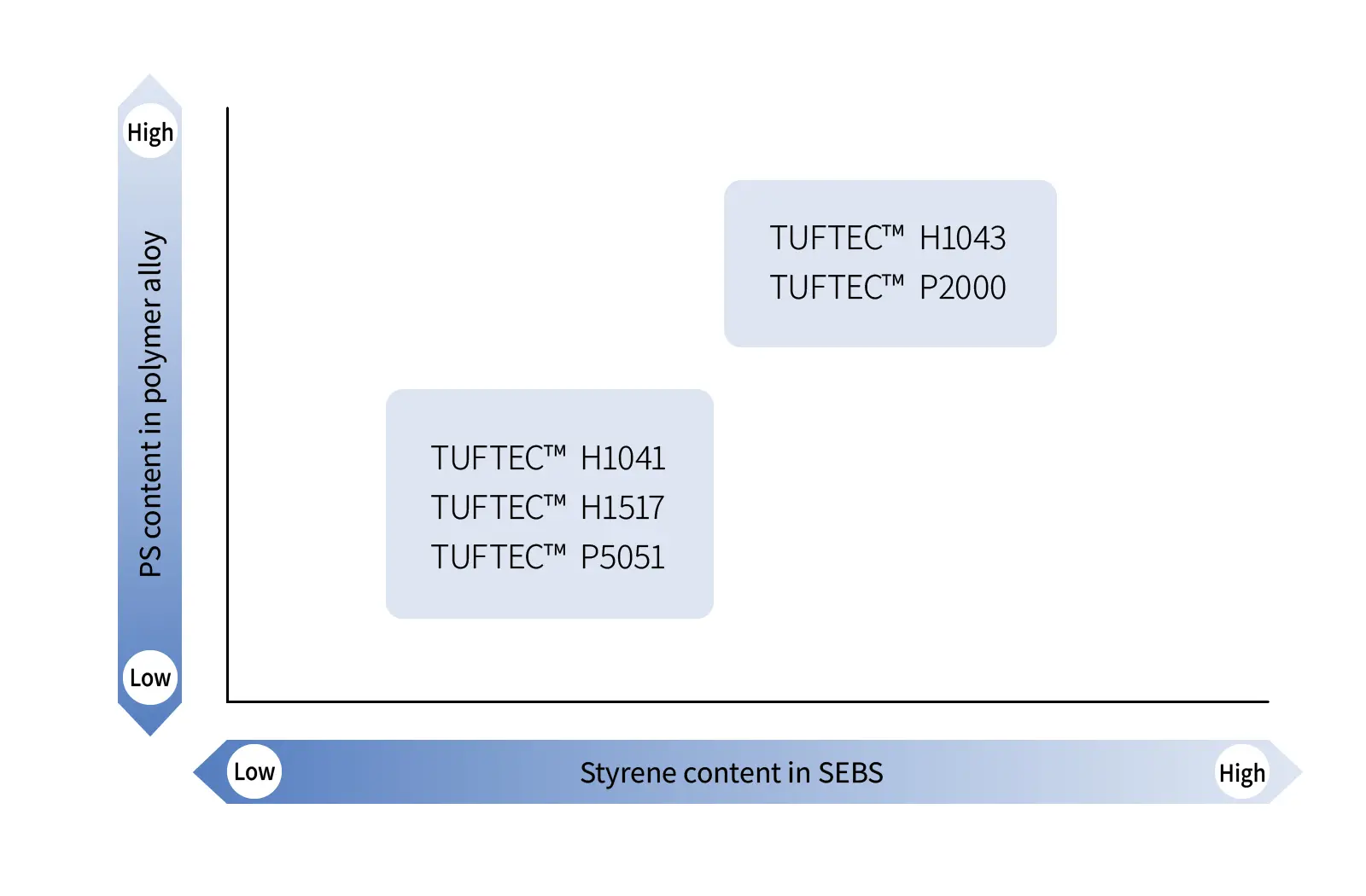

Optimal Grades

TUFTEC™ offers a variety of optimal grades based on the styrene content in SEBS.

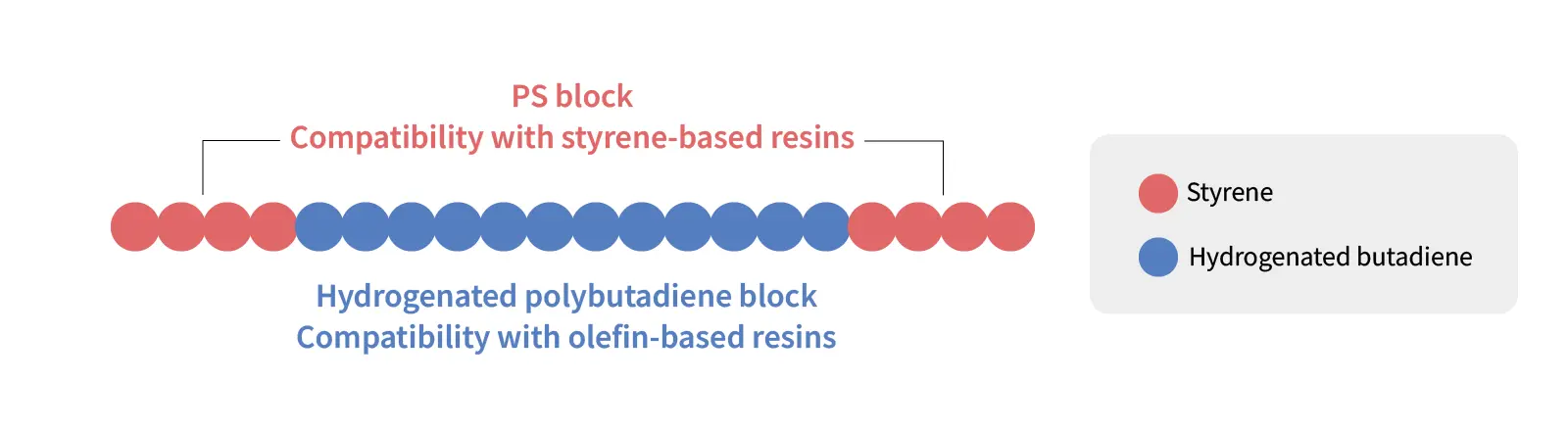

Why TUFTEC™ Excels at Compatibilizing Styrenic-Olefinic Resins

TUFTEC™ is composed of polystyrene blocks and hydrogenated polybutadiene (ethylene-butylene) blocks. The polystyrene blocks have good compatibility with styrenic resins, while the hydrogenated polybutadiene blocks have good compatibility with olefinic resins, making it highly effective as a compatibilizer for styrenic resin/olefinic resin alloys.

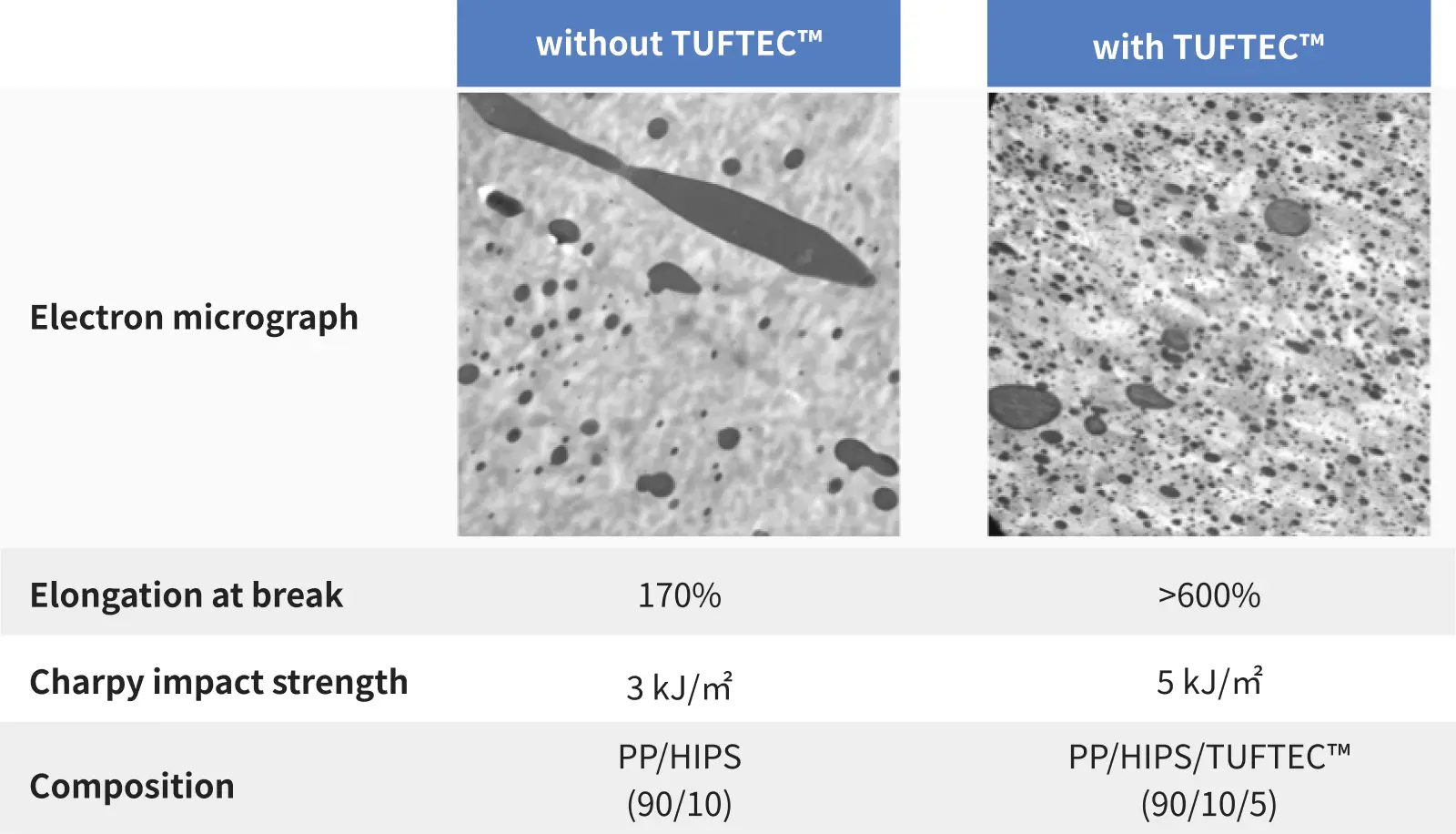

TUFTEC™ Enables Polymer Alloys with Superior Mechanical Properties

Polypropylene (PP) and polystyrene (PS) are resins that do not mix with each other, so if they are alloyed without using a compatibilizer, the two resins tend to separate. Also, the weak bonding at the PP/PS interface causes a decrease in impact resistance. However, the addition of TUFTEC™ promotes compatibilization between PP and PS and strengthens the bonding at the interface. As a result, it becomes possible to obtain a polymer alloy with improved mechanical properties.

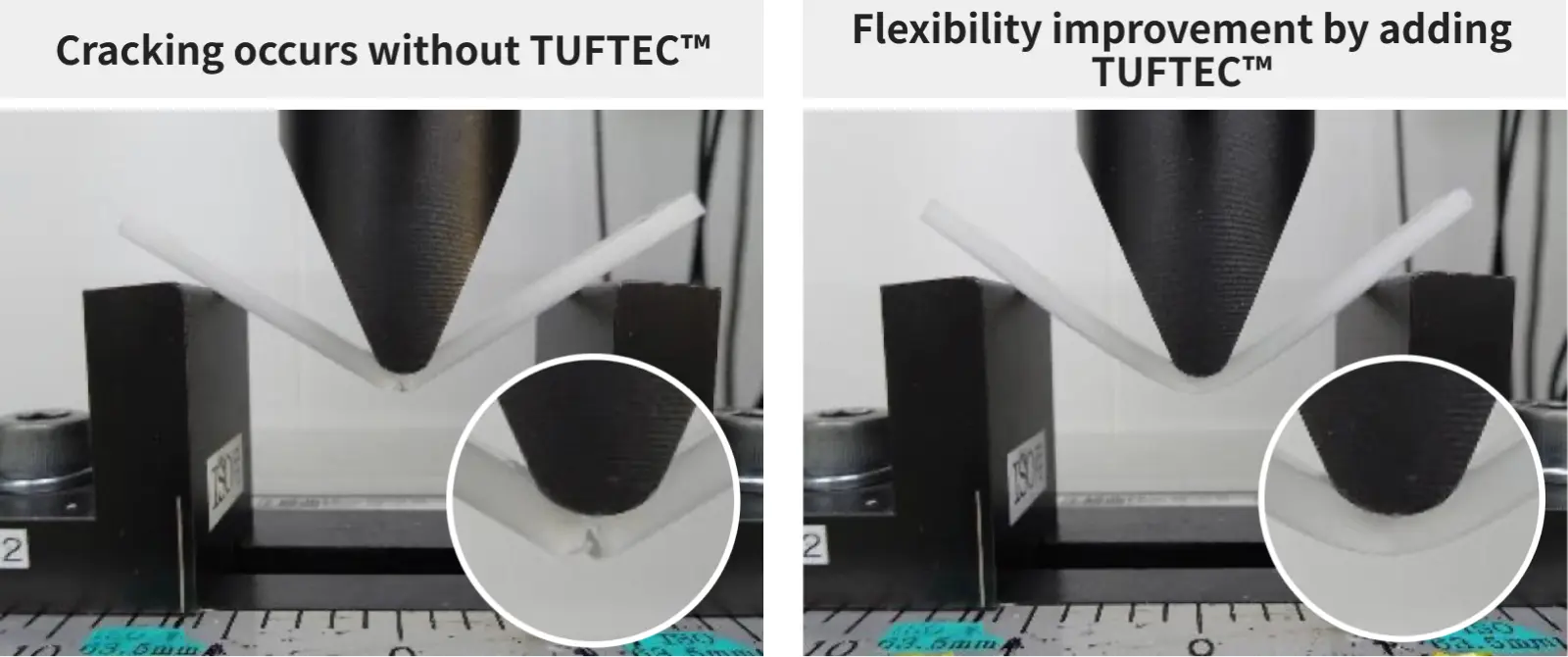

TUFTEC™ Improves Interface Strength, Preventing Molding Cracks

When TUFTEC™ is used as a compatibilizer, the interface strength of PP/PS increases, reducing interface delamination. Therefore, it is possible to suppress cracking when fatigue is applied to the molded product.