Contributing to Multi-Material Design and Development Through Bonding Dissimilar Materials

Asahi Kasei's unique terminal amine-modification technology of TUFTEC™ AP101 enables the bonding of polyolefins (PP, PE) and polar materials. The flexibility of the elastomer alleviates stress on the bonded area, preventing cracking and peeling.

Are You Facing Challenges with Bonding Dissimilar Materials?

-

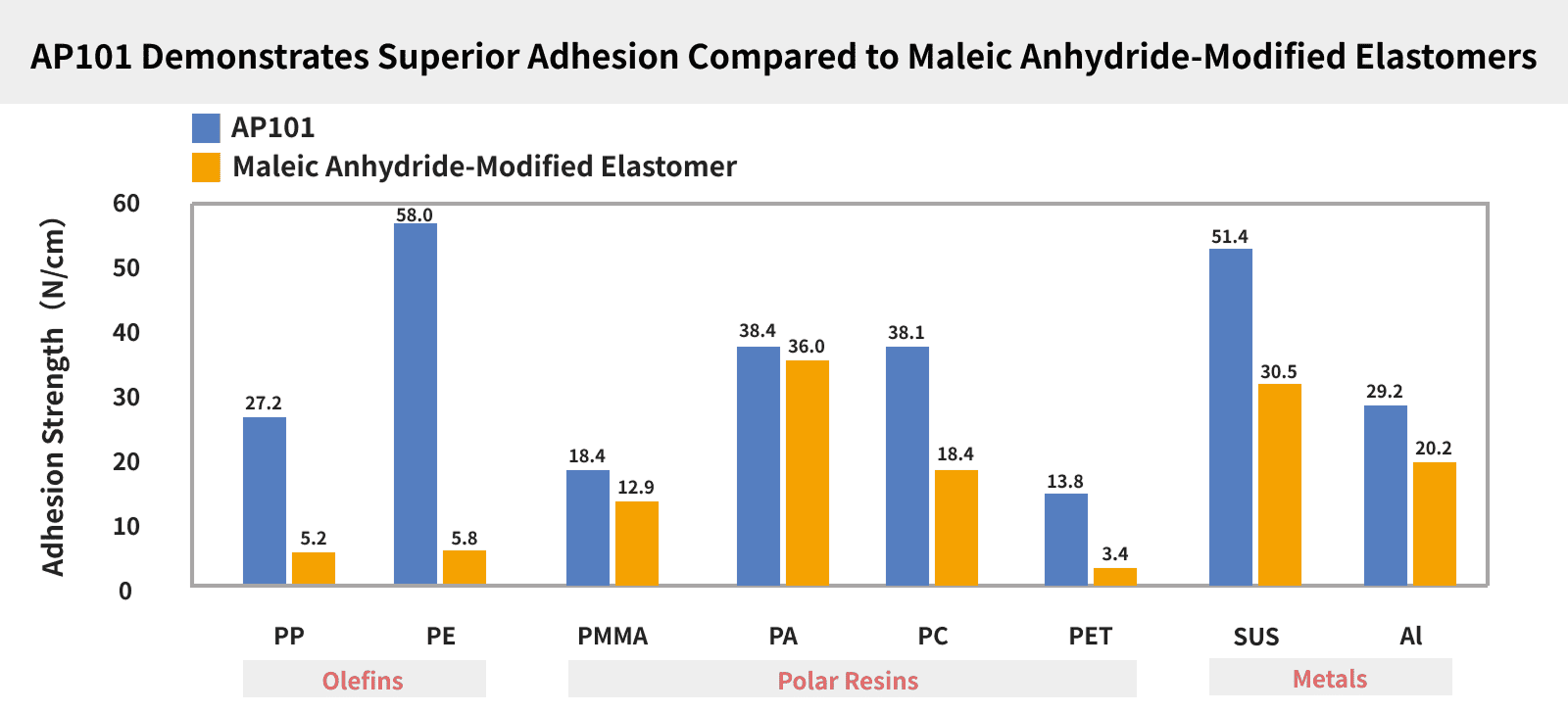

Difficulty in bonding polyolefins and polar materialsTUFTEC™ AP101 exhibits excellent adhesion to PP and PE. It also bonds well with various polar materials, including polar resins and difficult-to-bond metals like aluminum (Al), making it suitable for bonding dissimilar materials in multi-material applications.

-

Lack of flexibility in adhesives, resulting in hardness and brittleness / cracking and peeling due to the difference in the coefficients of linear expansion of adherendsTUFTEC™ AP101 is a styrenic thermoplastic elastomer that possesses flexibility and elasticity, which is expected to alleviate stress generated at the bonding interface.

-

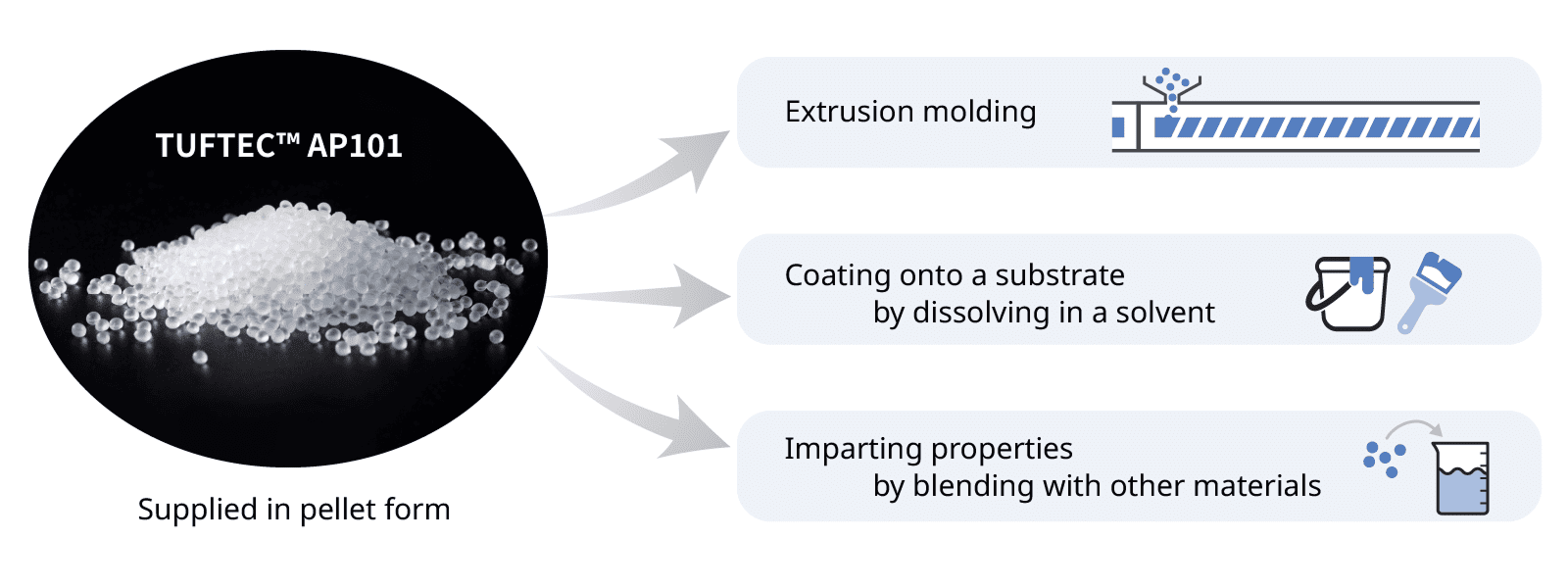

Limitations in the processing methods and handlingTUFTEC™ AP101 is available in pellet form, which allows for the formation of adhesive layers through extrusion molding or solvent coating. Furthermore, it can be added as an additive to other materials for modification purposes, offering superior processability and greater flexibility in usage compared to adhesives that require curing or sheet-like adhesives.

As a solution to these challenges in bonding dissimilar materials, Asahi Kasei's "TUFTEC™ AP101" is being utilized and considered.

Please Feel Free to Contact Us with Any Issues Regarding Bonding Dissimilar Materials

TUFTEC™ AP101 solves challenges in bonding dissimilar materials, enhances product performance, and increases design freedom. If you have any issues regarding bonding dissimilar materials, please feel free to contact us.

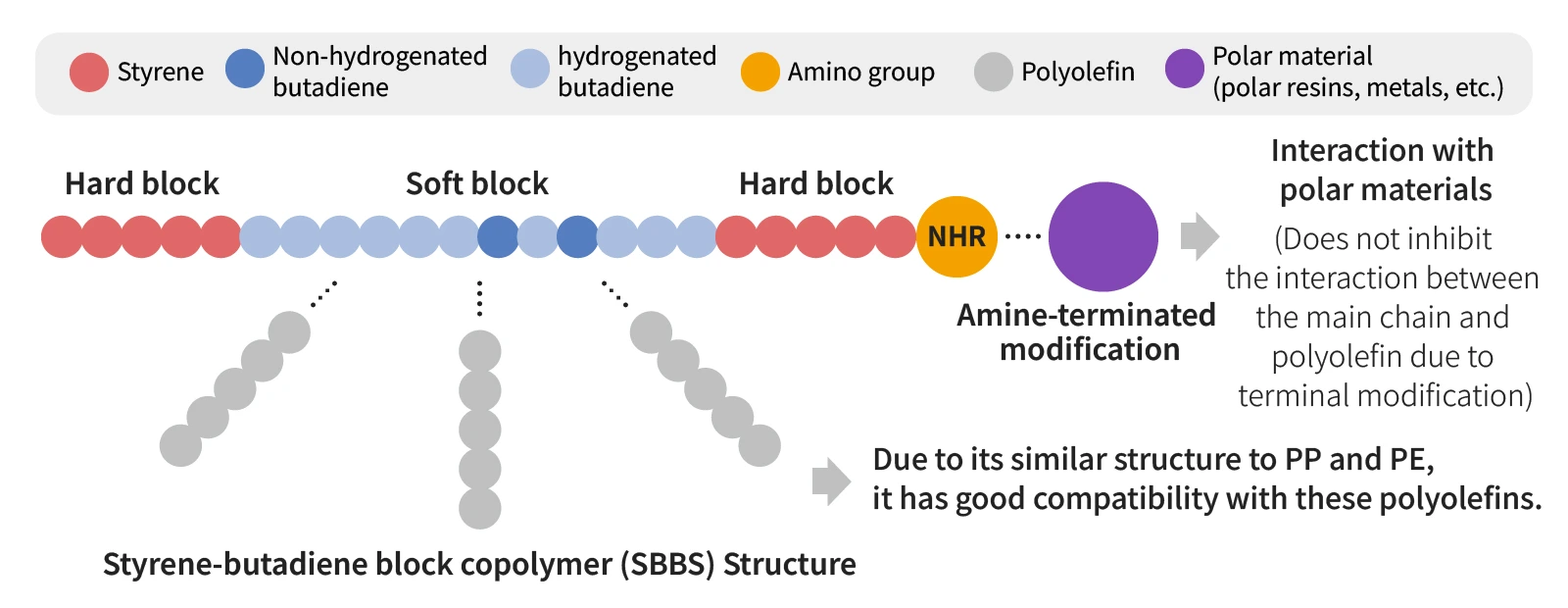

Feature 1: Interaction with Both Polyolefins and Polar Materials

Generally, polar modification groups such as maleic anhydride are used for bonding with polar materials. However, maleic anhydride modifies the soft block main chain of the elastomer, hindering interaction with polyolefins.

TUFTEC™ AP101 is an elastomer with amino groups-modified at the molecular terminals. This enables interaction with polar materials through the amino groups, while not hindering the interaction between the soft block and polyolefins, resulting in good compatibility with polyolefins as well as polar materials.

This characteristic allows it to strongly interact with both polyolefins and polar materials such as polar resins, metals, and fillers, exhibiting excellent adhesion to them.

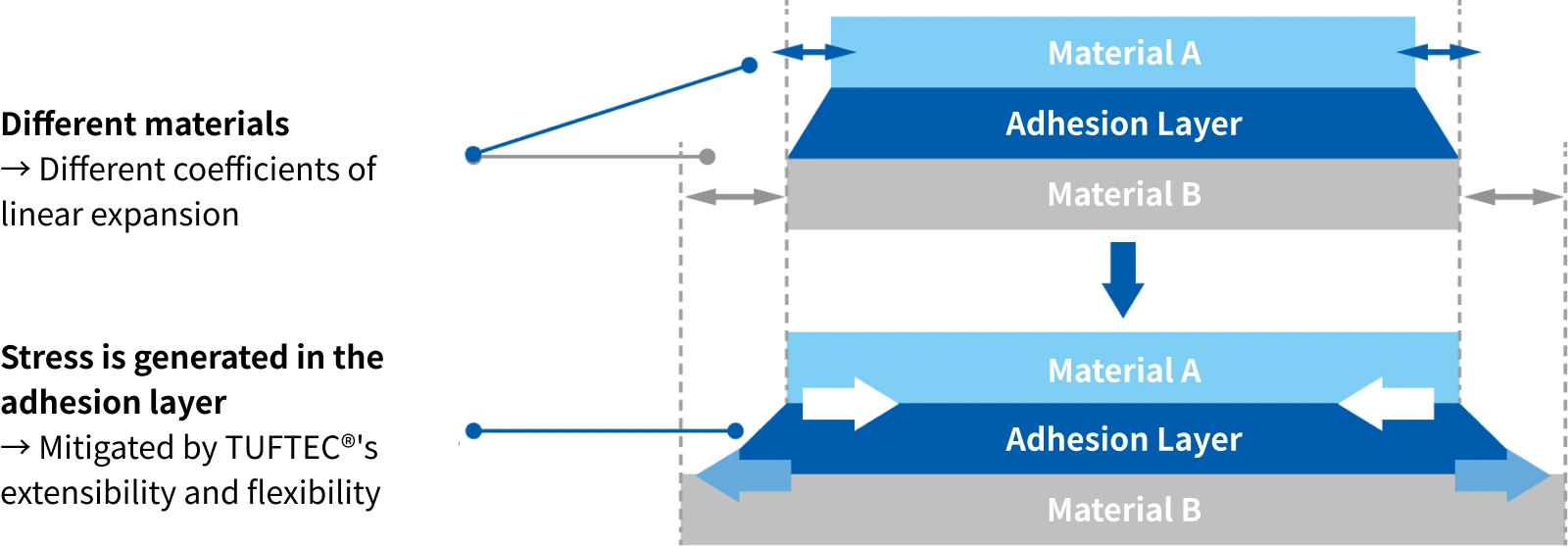

Feature 2: Stress Relaxation Due to Flexibility Prevents Cracking and Peeling

When bonding different materials, stress occurs due to differences in the coefficients of linear expansion, which can lead to peeling and cracking.

TUFTEC™ AP101 not only bonds polyolefins and polar materials, but its high elasticity and flexibility effectively alleviate stress generated at the bonding interface. This prevents peeling and cracking caused by temperature changes or external stress.

Feature 3: Excellent Processability and Flexibility in Usage

Conventional adhesives have limitations in processing methods and handling, such as requiring curing or needing to be cut out to fit the shape of the adherend in the case of sheet-like adhesives.

TUFTEC™ AP101 is provided in pellet form, which allows for the formation of adhesive layers through various processing methods such as extrusion molding and solvent coating. It can also be used as an additive to other materials, offering superior processability and greater flexibility in usage.

Appendix: Solvent solubility of TUFTEC™︎ AP101

| Solvent |

Solubility (AP101 conc.; 25 wt. %) |

Solution Viscosity [mPa·s] (at 25 °C, AP101 conc.; 25 wt. %) |

| Toluene | Soluble | 750 |

| Toluene/MEK* = 9/1 (v/v) | Soluble | 1,200 |

| Toluene/MEK = 8/2 (v/v) | Soluble | 2,000 |

| Toluene/MEK = 7/3 (v/v) | Moderately Soluble | 9,000 |

| Toluene/MEK = 6/4 (v/v) | Insoluble | — |

| Xylene | Soluble | 820 |

| Methylcyclohexane (MCH) | Soluble | 950 |

| Tetrahydrofuran (THF) | Soluble | 1,050 |

* MEK : Methyl Ethyl Ketone

Basically, TUFTEC™︎ AP101 is insoluble in ketone, such as MEK and ethyl acetate.

We Support Your Product Development Through Bonding Dissimilar Materials

TUFTEC™ AP101 contributes to the realization of bonding between polyolefins and polar materials. If you are exploring the development of new products utilizing bonding dissimilar materials, please feel free to contact Asahi Kasei. We will propose the optimal solution tailored to your needs.