Specifications and properties

Advantage of SUNNOVA™

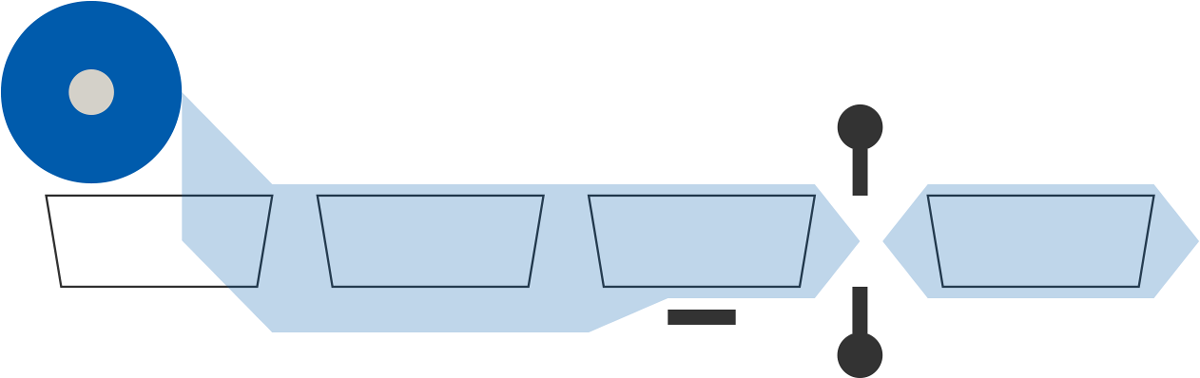

| Process |

Packaging Machine

|

||||

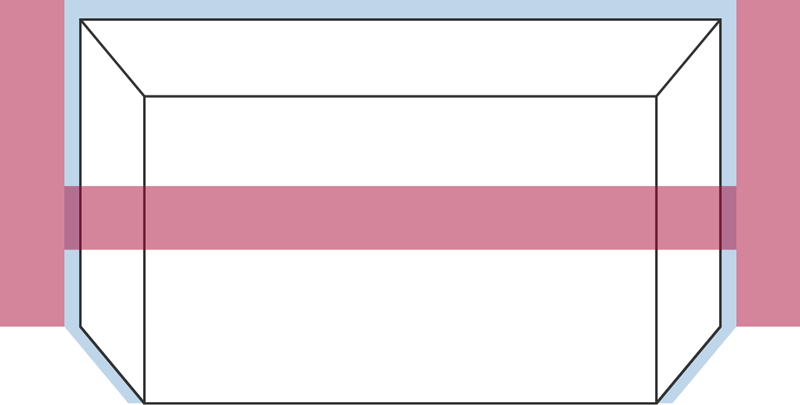

| Points | Handling | Packaging machine suitability (runnability) |

Heat sealability (air-tightness) |

||

| ■Lightness Easy to handle due to its low specific weight and light film roll. |

■Tensile elongation Reduces packaging defects. ■Slidability Stable packaging operation is possible. ■Tear strength Reduces packaging problems caused by tear propagation due to its high tear strength. |

■Heat resistance Prevents perforation during sealing. ■Low temperature sealing Seals well even at low temperatures. |

|||

| Film performance | Specific weight | Tensile elongation | Slidability | Tear strength | Low temperature sealing |

| SUNNOVA™ T400 | ◎ | ○ | ○ | ○ | ◎ |

| SUNNOVA™ SK100 | ◎ | ○ | ○ | ◎ | ○ |

| Conventional products | ○ | ○ | △~○ | ○ | × |

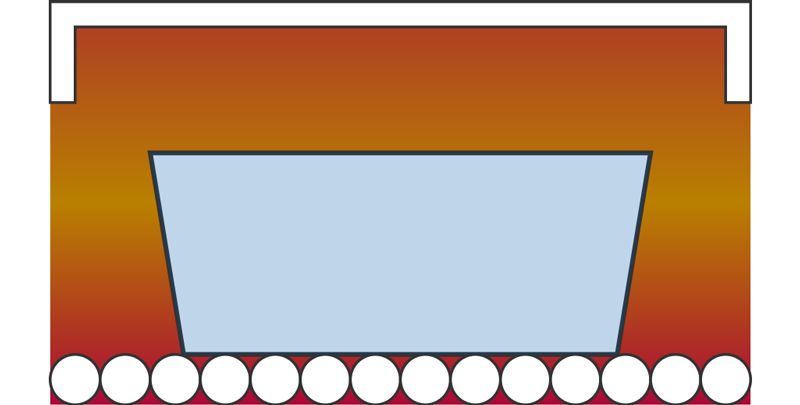

| Process | Shrink tunnel |

Pillow shrink wrapping |

||||

| Points | Shrinkage | Merchantability of wrapped products | Long shelf life ability of contents | |||

| ■High shrinkage at low temperatures Prevents thermal degradation of perishable foods. Produces tighter packaging with fewer wrinkles. ■Low shrinkage stress Produces beautiful packaging without deforming the container. |

■Visibility Excellent transparency, making it easier to see the contents. ■Recover-ability Prevents loosening and denting of the film during transportation and stacking in stores. |

■Gas barrier-ability Retains the freshness and color of the contents because it is impermeability to oxygen, nitrogen, and carbon dioxide. ■Anti-fogging It maintains the visibility of the contents for a long time. |

||||

| Film performance | High shrinkage at low temperatures | Heat shrinkage stress | Transparency | Indentation recovery time | Gas barrier-ability | Over time anti-fogging |

| SUNNOVA™ T400 | ◎ | ◎ | ○ | ○ | ○ | ◎ |

| SUNNOVA™ SK100 | ◎ | ○ | ○ | ○ | ◎ | ◎ |

| Conventional products | ○ | △~○ | △ | ○ | ○ | △~○ |

Physical properties table of SUNNOVA™

| Test items | Unit | Test method | SK100 | T400 | |

| Film strength | Tensile strength(MD/TD) | MPa | ASTM D-882 |

91 / 62 | 87 / 70 |

| Tensile elongation(MD/TD) | % | ASTM D-882 |

77 / 113 | 81/ 121 | |

| Tensile elasticity(MD/TD) | MPa | ASTM D-882 |

561 /395 | 464 / 384 | |

| Tear strength(MD/TD) | cN | Asahi Kasei method | 4.6 / 7.1 | 3.1 / 4.2 | |

| Optical properties | Haze | % | ASTM D-1003 |

1.9 | 1.5 |

| Gloss | % | ASTM D-2457 |

151 | 153 | |

| Permeability | Water vapor transmission rate | g /㎡/ day | ASTM F-1249 |

20 | 36 |

| Oxygen permeability rate | cc /㎡/ day・ MPa |

ASTM D-3985 |

101 | 132 | |

| Shrinkage | Maximum shrinkage rate(MD/TD) | % | Asahi Kasei method | 44 / 41 | 48 / 42 |

| Packaging machine suitability | Sealing temperature range* (top seal reference value) |

℃ | Asahi Kasei method | 115~140 | 110~135 |

| Tunnel temperature range* (reference value) |

℃ | Asahi Kasei method | 115~145 | 110~140 | |

| Dynamic friction coefficient | ― | Asahi Kasei method | 0.27 | 0.35 |

(Note) The above data is an example and is not a guranteed value.

*Measured values vary depending on the packaging machine.