Plastic reduction

The thin-wall compatible grades are available through film-forming technology, enabling plastic reduction.

Waste reduction

Since the thickness is thin and specific weight is small, packaging waste can be reduced compared to PVC stretch film.

| Example of waste weight comparison | ||

| Material・Packaging formats | Weight ratio | Basis of calculation (specific gravity x thickness x using area ratio) |

|---|---|---|

| PVC stretch film・ Overwrap shrink wrapping |

100 | 1.40 x 11.0 x 1.0 = 15.40 |

| Polyolefin based shrink film・ Overwrap shrink wrapping |

66 | 0.92 x 11.0 x 1.0 = 10.12 |

| Polyolefin based shrink film・ Pillow shrink wrapping |

46 | 0.92 x 11.0 x 0.7 = 7.08 |

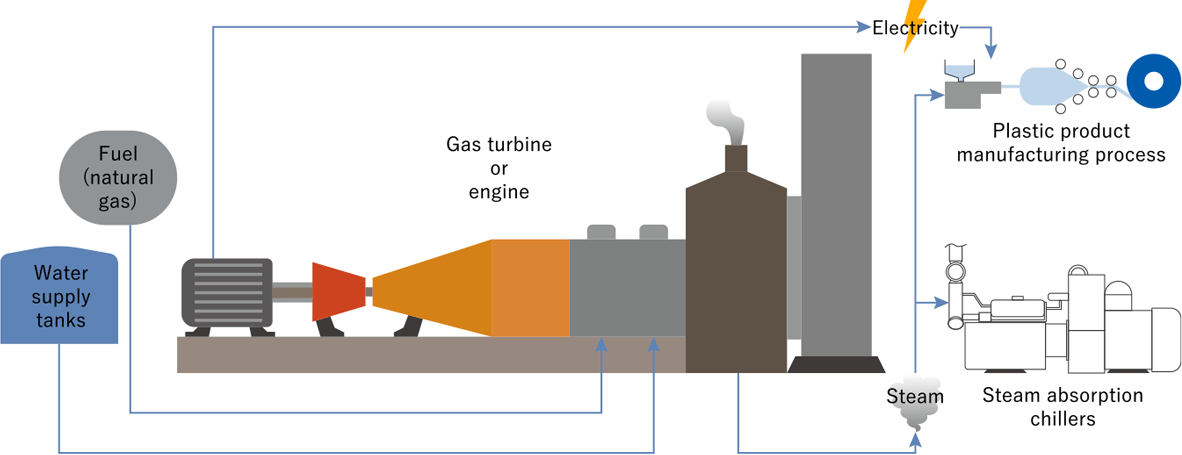

Co-generation system (Energy conservation efforts)

SUNTEC S FILM™ utilizes a co-generation system in its production process, thereby increasing the efficiency of energy use. Co-generation system uses waste heat (steam) from power generation for air conditioning, hot water supply, and other heat sources. Since there is no need to create new steam, the system reduces carbon dioxide emissions, which is a measure to prevent global warming. In addition, by switching from heavy oil to city gas as fuel, we have reduced the emission of sulfur compounds to as close to zero.

Conceptual diagram of co-generation system

PVC free

SUNTEC S FILM™ is a polyolefin based film that does not generate hydrogen chloride gas when burned, thus reducing the environmental impact.