- Chemical industry

- Separation technology

Manifesting effects in automation, labor saving, and increased cleanliness of the separation, concentration, and purification processes for manufacturing chemicals from both the software and hardware sides.

contents list

Microza responds to various challenges in the chemical application

Provide sufficient filtration precision

Privide an efficient desalination and purification system

Provide compact system that can both purify and concentrate slurry in one unit

Realize continuous purduction instead of batch purduction

Improve the work environment with the closed purification system

Why Microza?

Characteristics of Microza ultrafiltration (UF) membrane module

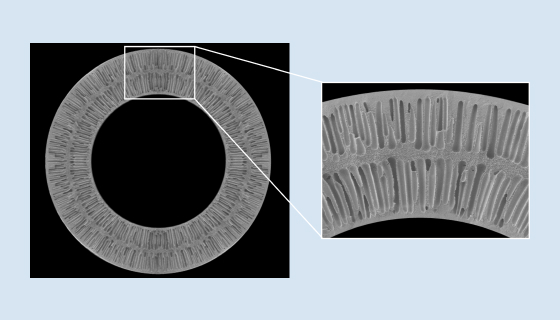

Ordinary hollow fiber ultrafiltration (UF) membrane has its separation performance only on a very thin layer (skin layer) on either the inner or outer surface of the membrane (single-skin structure). On the other hand, all Microza UF membranes have separation performance on both the inner and outer sides of the hollow fiber membrane (double-skin structure).

During the purification and concentration process, the inner surface of the hollow fiber membrane is subjected to load. The resultant abrasion damage may lead to leakage of slurry. However, Microza has an outer surface also having a skin layer with a separation performance similar to the inner surface, and such damage does not result in sudden leakage.

Characteristics of Microza microfiltration (MF) membrane module

・The hollow fiber microfiltration (MF) membrane is produced using polyvinylidene difluoride (PVDF) manufactured by thermally induced phase separation (TIPS). Ordinary PVDF membranes are manufactured using non-solvent-induced phase separation (NIPS). PVDF membrane by TIPS is superior in durability compared to PVDF membrane by NIPS.

・When a membrane module is used for filtering slurry that contains oxidizing agent or is repetitively washed with chemicals that contain an oxidizing agent, PVDF membrane module manufactured by NIPS is susceptible to damage and increased risk of leakage.On the other hand, Asahi Kasei’s PVDF membrane modules are all spun using TIPS and are thus highly resistant to chemicals and have high strength.

・There are hollow fibers of inner diameters of 1.1 mmφ, 1.4 mmφ, and 2.6 mmφ. Purification and concentration of micron-size and emulsion for chemical industrial applications can be achieved with fibers of 1.4 mmφ, and fibers of 2.6 mmφ are feasible for the purpose of high concentration.

Differences from other technologies

*Depending on the products and conditions

Microza is …

- Smaller space

- Less energy consumption and power cost by smaller circulating pump capacity

- Less initial costs

Microza is …

- Unified purification and concentration process

- Better work environment (less noise, no risk of rotating body, and no need of work of disassembling unit)

- Better production yield of slurry or emulsion due to better separation precision

Microza is …

- No need for scraping

- Recovery of uniform particles by combining with a spray drier (No need for regrinding when collecting powder by press filter)

- No need of touching the liquid by the operator until product recovery

Our products

Pencil-scale module

A small-scale module is appropriate for checking the separation performance in the intended chemical process. Please use it for beaker-scale evaluation.(Note: Pencil-scale testing module cannot be used to acquire engineering data.)

Laboratory-scale testing module

Laboratory-scale module is used for acquiring engineering data related to designing the Microza filtration system. After checking filtration performance using a pencil-scale testing module, use a laboratory-scale testing module for making evaluations at the liter scale.It also can be used for bench-scale production and sample work.

UF membrane; AV series

AV series is polyacrylonitrile (PAN) ultrafiltration (UF) membrane modules for actual facilities. The upper and lower circulation-side openings are connected to pipes with flanges; and a ball head lock nut is used at the connection between the filtrate-side nozzle and pipe. The housing of the module is polyvinyl chloride (PVC).

UF membrane; SW series

SW series is polysulfone (PSf) ultrafiltration (UF) membrane modules for actual facilities. The upper and lower circulation-side openings are connected to pipes with flanges; and a ball head lock nut is used at the connection between the filtrate-side nozzle and pipe.The housing of the module is also polysulfone (PSf, white).

UF membrane; AP/SP series

AP and SP series are ultrafiltration (UF) membrane modules of high sanitation performance and are widely used in food, pharmaceutical, and bioprocess applications. Both circulation and filtrate-side nozzles are connected to the pipes of the filtration systems with ferrules.

Case studies

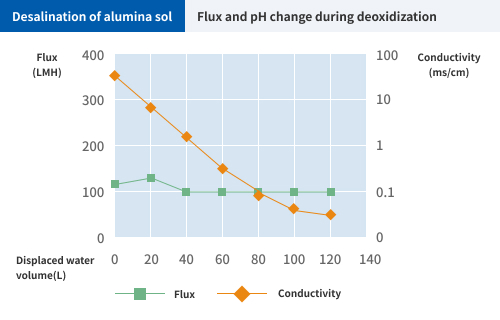

- Chemical campany A

Reduce desalination time

- Background

- The existing facility used specific gravity difference separation but was poor in treatment efficiency. The manufacturer was investigating the introduction of a new separation process.

- Proposal

- We proposed a Microza system for more efficient desalination and purification.

- Results

- The manufacturer could reduce the time required for desalination.

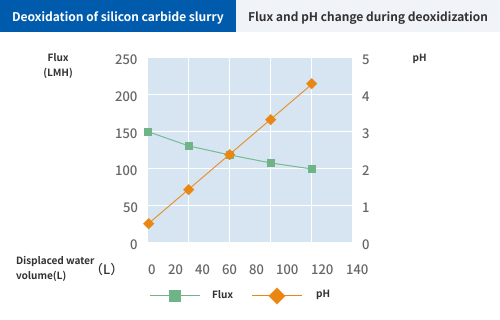

- Chemical campany B

Reduce desalination time

- Background

- The manufacturer developed a new product that required deacidification and purification.

- Proposal

- We proposed a Microza system for more efficient and high-yielding deacidification and purification.

- Results

- The manufacturer achieved mass production of high-purity products, where the deacidification and purification process was incorporated.

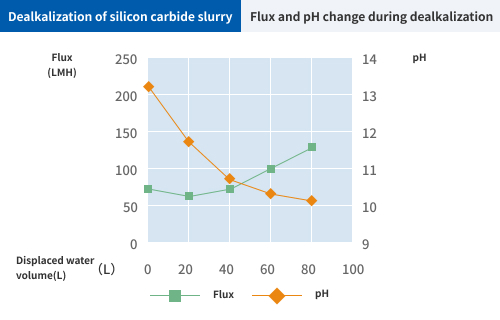

- Chemical campany C

Mass production of high-purity products including desalination process

- Background

- The manufacturer developed a new product that required deacidification and purification.

- Proposal

- We proposed a Microza system for more efficient and high-yielding deacidification and purification.

- Results

- The manufacturer achieved mass production of high-purity products, where the deacidification and purification process was incorporated.

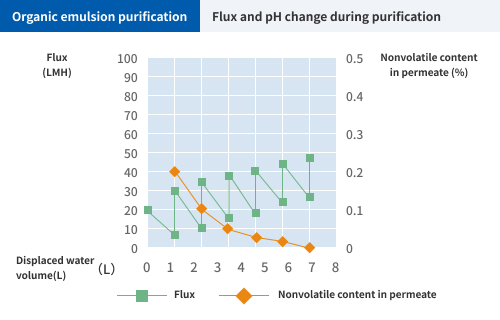

- Chemical company D

Improve the purification efficiency of low-molecular-weight components

- Background

- The manufacturer required an efficient system for filtering low-molecular-weight components from organic emulsions.

- Proposal

- We proposed a Microza system for efficient and high-precision filtration.

- Results

- The manufacturer could improve the purification efficiency of low-molecular-weight components.

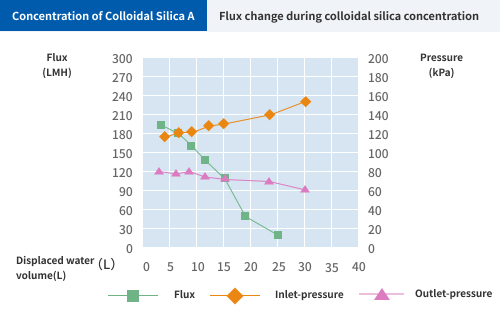

- Chemical company E

High-degree concentration of colloidal silica

- Background

- The manufacturer required a system that highly condenses colloidal silica.

- Proposal

- We proposed a Microza filtration system that can achieve a high-degree concentration.

- Results

- The manufacturer achieved high-degree concentration of colloidal silica.

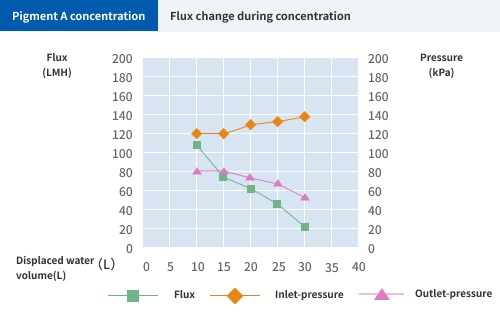

- Chemical company F

Efficient pigments concentration

- Background

- The manufacturer required a system for condensing pigment dispersion, from which impurities are removed in advance, to a specified concentration.

- Proposal

- We proposed a Microza system for efficient and highly precise filtration.

- Results

- The manufacturer achieved an efficient concentration of pigments.