What is Water treatment process(UF/MF)?

Microza for water treatment is

high in quality, performance, and durability.

It actualizes effective, efficient, and environment-friendly separation

and clarification that suit the purpose of each customer.

Microza, containing the hollow fiber membrane of Asahi Kasei, is feasible for separation and clarification in a wide range of fields, including electronics, water supply, sewage, industrial water, industrial wastewater, and water recycling, and has been widely implemented in many countries including Japan. Being the pioneer and the most experienced and having the largest accumulation of technologies out of all membrane manufacturers, we support customer solutions on both software and hardware sides including system designing.

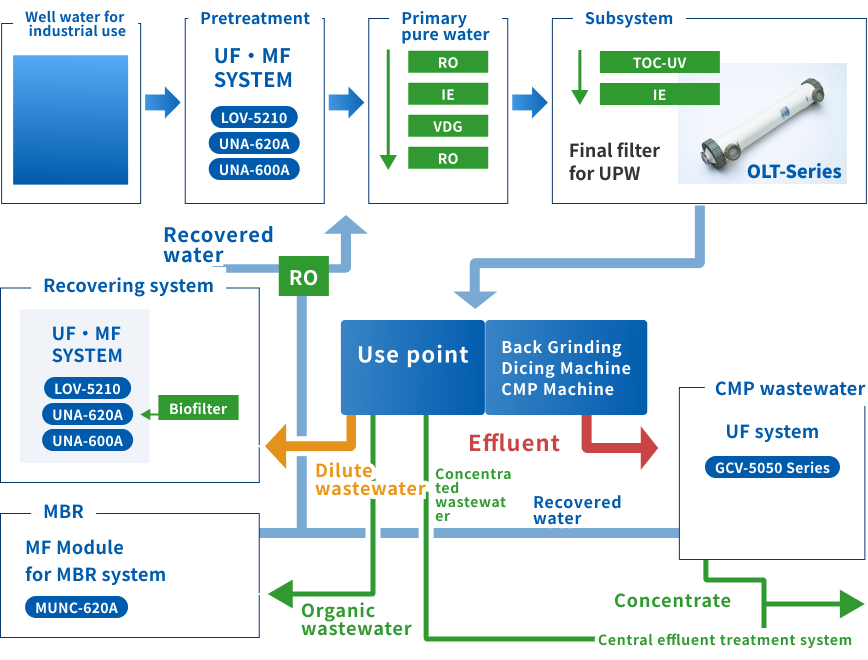

Example of application in an electronics factory Text in the chart: Primary DI water

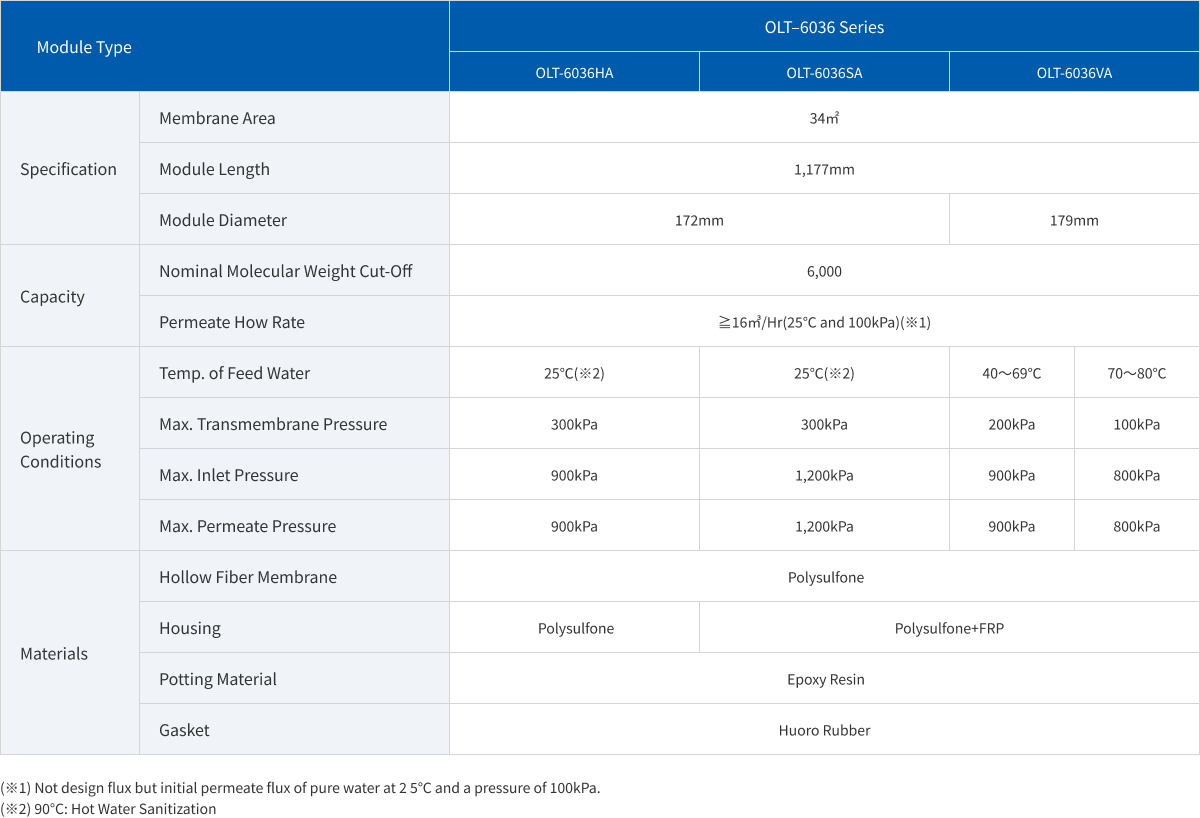

OLT series

Product overview

OLT series is a high-quality UF membrane module appropriate for producing ultrapure water for the most advanced large-scale integration (LSI).

Fields and applications

Production of ultrapure water in most advanced large-scale integration (LSI) plants

Product specifications

Product characteristics

Most abundant operation results and highest reliability in the LSI industry

The series has been widely implemented by manufacturers of the most advanced LSI and received enormous trust from them on product quality.

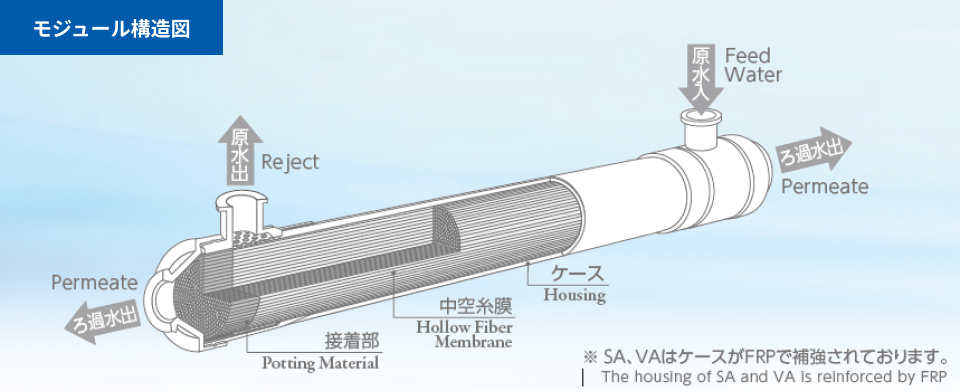

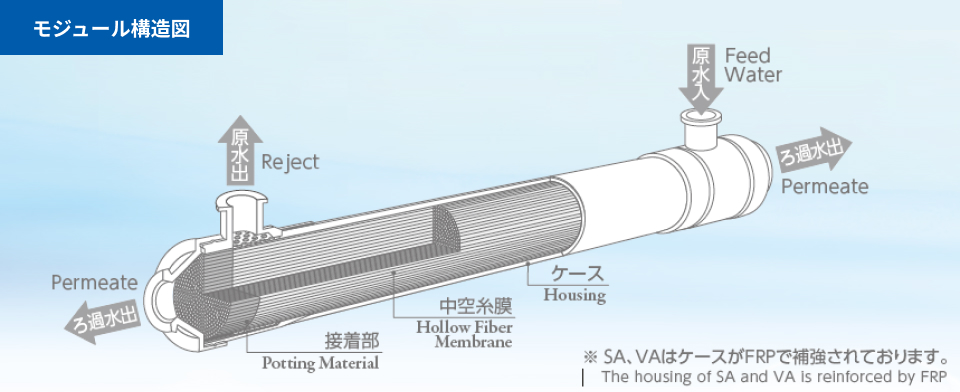

Highly reliable double skin structure

Original double-skinned hollow fiber membrane that has fine inner and outer surfaces enables the production of higher precision water by filtering three times.

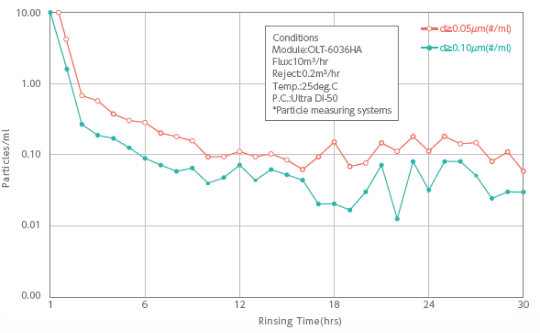

Advanced Cleanliness

Components of selected materials with low extractability facilitate quick total rinse-up of particles and organic carbon (TOC) and quick recovery of specific resistivity.

High pressure resistant. A full lineup of high heat-resistant lineups

We have a lineup of 1,200 kPa (40°C) pressure-resistant types and 800 kPa (80°C) heat-resistant/pressure-resistant types to meet your purposes.

OLT-6036 SERIES PARTICLE RINSE UP DATA

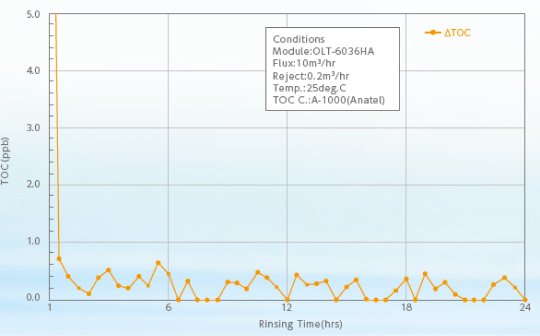

OLT-6036 SERIES TOC DATA

OAT series

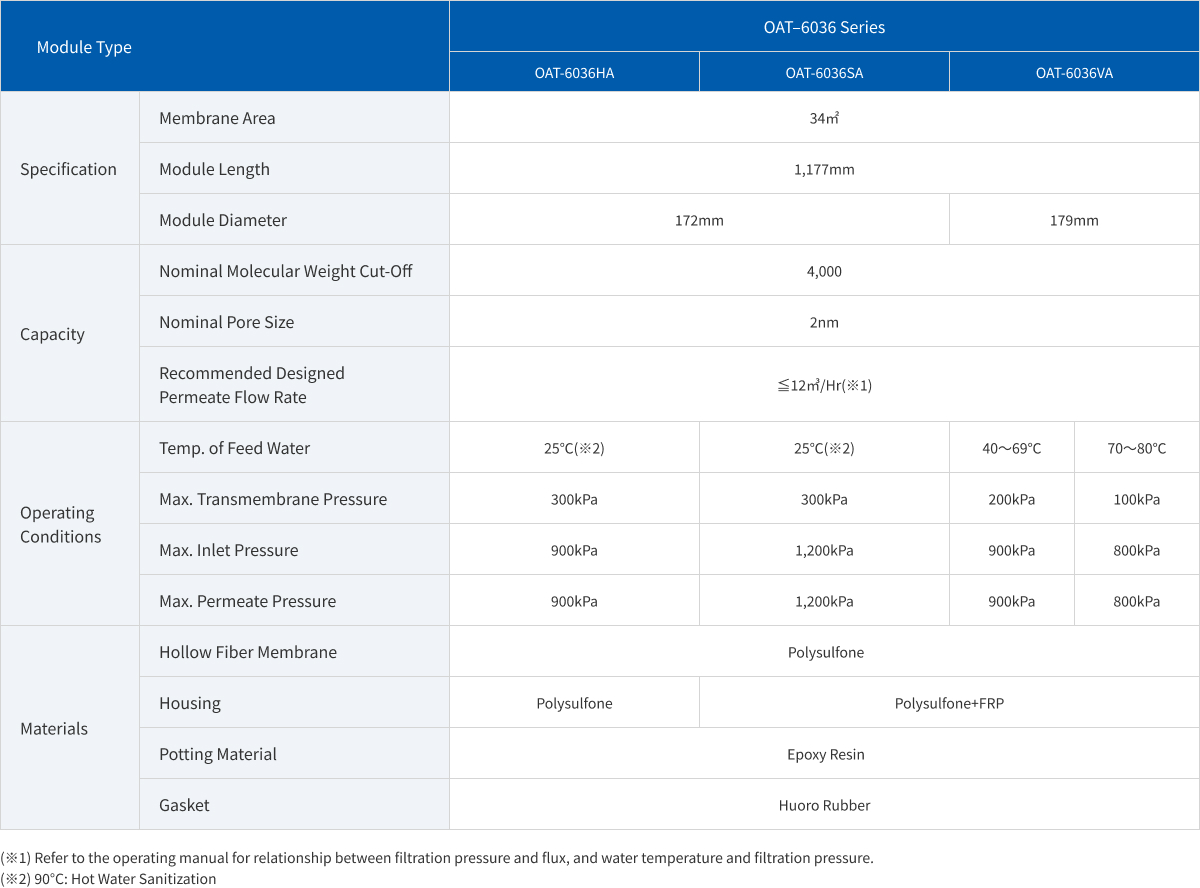

Product specifications

OAT series is a UF membrane module with enhanced particulate removal performance suitable for ultra-pure water production for next-generation large-scale integration (LSI).

Fields and applications

Production of ultrapure water in most advanced large-scale integration (LSI) plants

Product specifications

Product characteristics

The next-generation version of OLT modules, widely implemented in LSI manufacturing

UF membrane modules are now available, having the same highly reliable double skin structure as our OLT series, which has been widely implemented globally in LSI manufacturing, but with increased performance of particulate removal.

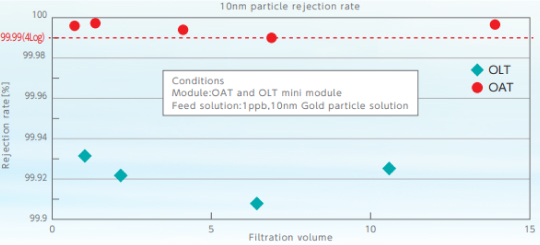

The performance of removing 10nm particulates improved

A 99.99% removal is attained for 10nm particulates. It exerts the maximum effects in reducing particulates in permeate.

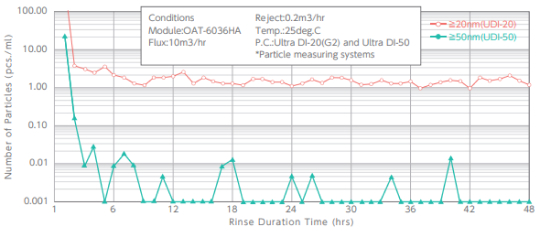

Ultra cleanliness

Components of selected materials with low extractability, which are manufactured in an exclusive process for ultrapure water membrane modules, facilitate quick total rinse-up of particles and organic carbon (TOC) and quick recovery of specific resistivity.

High-pressure and heat-resistant products covered in the lineup

Some modules can resist high pressures of up to 1,200 kPa (40°C) and those resisting heat and pressure of up to 800 kPa (80°C), meeting diverse customers’ purposes.

OAT-6036 SERIES PARTICLE RINSE UP DATA

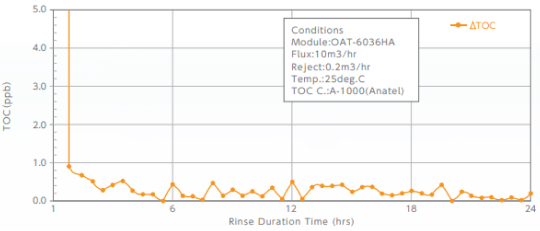

OAT-6036 TOC DATA

OAT-6036 SERIES PARTICLE REJECTION PERFORMANCE

UN series

Product Overview

UN series is feasible for water purification, sewage treatment, and recycling of industrial wastewater.

Polyvinylidene difluoride (PVDF) has high mechanical and chemical strengths and has been widely used as a material suitable for MF and UF membranes. Asahi Kasei has over 40 years of experience and results as a pioneer manufacturer of PVDF hollow fiber membranes.

Fields and applications

- Water purification plants

- Water supply in the industrial complex

- Reuse of effluent from a sewage-treatment plant

- Treatment of industrial wastewater such as in fields of power generation, steel, paper manufacture, food, petroleum gas, and pharmaceutical industries.

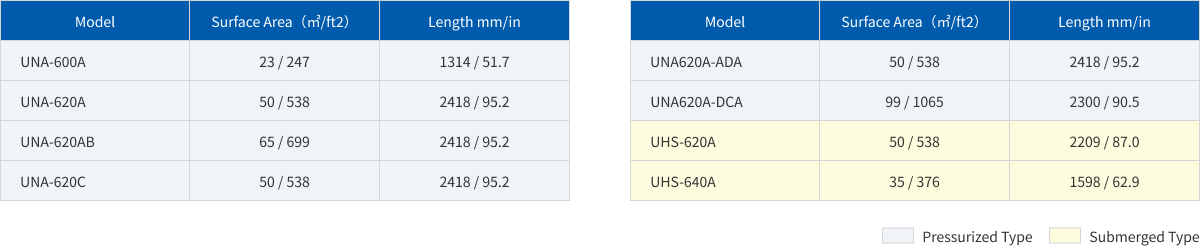

Product specifications

Product characteristics

High mechanical strength & chemical resistance

The membranes manufactured using thermally induced phase separation (TIPS) have higher mechanical strength and chemical resistance compared to hollow fiber membranes produced using non-solvent induced phase separation (NIPS). The membranes are symmetric and have high cross-linkage and porosity.

Use under a wide range of conditions

The modules are implementable even at sodium hypochlorite concentration of up to 5,000 mg/l, sodium hydroxide concentration of up to 4%, and up to 10% of hydrochloric acid, sulfuric acid, and oxalic acid.

Lower operation cost

The high durability enables long-life use. Reduced frequency of replacement contributes to reduced operating costs

Contribution to reduction of initial investment

Stable operation enables the design flux to be set high, contributing to the reduction of investment costs.