Membrane filtration systems for Microza products

From proposal of membrane product selection to design and fabrication of the optimum equipment for your microza products

Microza has been highly rated for having high-quality and magnificent supply service systems throughout its 40-year history of membrane development. It has no equal in Japan in applications for large-scale integration (LSI), chemical products, automotive, pharmaceuticals, food products, etc. In applications for water purification and wastewater and sewage recycling, it has a world eminent share.

Asahi Kasei contributes to solving all kinds of troubles of customers by using knowledge and experiences obtained from enormous results in and outside Japan and know-how accumulated via technological services provided over the years.

For introducing Microza, we are providing consultation services for selecting the optimum membrane product, engineering supports on optimum operation methods and systemization, and design and manufacturing services of membrane filtration systems optimum for Microza products. Even after installation, support services by professional engineers are available in cases of operation trouble.

Pharmaceuticals

In the field of pharmaceuticals, Microza membrane filtration systems are

widely used for the purification of antibiotics, production of water for injection (WFI) and sterile water, etc.

System advantages

- The system can be designed to be fully automated, from filtration to washing, and maintenance-free, contributing to labor savings and refinement of processes.

- The advantages of being a module, such as in-line hot water disinfection and chemical washing, can be fully manifested.

- All systems, from tryout devices to large-scale facilities, are designed using software technologies backed by abundant experiences and accumulated technological knowledge.

Major application

- Production of water for injection (WFI) (depyrogenation)

- Purification of the bulk drug (depyrogenation)

- Purification of fermented liquid (removal of fungus/bacteria and deproteinization)

- Concentrated solutions of enzyme and protein (desalination and concentration)

- The concentration of vaccine and blood products (concentration)

Food

In the field of food, Microza membrane filtration systems are actively used not only for removing toxic substances but also in biological processes of raw materials preparation

as well as a wide range of purposes including enzyme concentration.

Major applications

- Purification of fermented liquid (removal of fungus/bacteria and deproteinization)

- Concentrated solutions of enzyme and protein solutions (desalination and concentration)

- Soy sauce (removal of lees, recovery of soy sauce remaining on the lees, sterilization)

- Sake (enzyme removal, microorganism elimination, and removal of lees)

- Honey, sugar alcohol, fermented seasoning liquid (deproteinization)

- Purification (removal of fungus/bacteria and deproteinization) of all kinds of extracts (marine, livestock, vegetable, fruit juice)

- Fucoidan, lycopene (desalination and concentration)

- Wine (clarification)

- Noodle soup, vinegar (microorganism elimination)

- Milk formula for baby (removal of fungus/bacteria)

Chemical

Microza systems are actively employed in the production of raw materials,

such as ceramic materials, materials related to inkjets, polishing material for semiconductors, IT-related materials, organic emulsion, and special functional materials.

Microza systems respond to the needs of concentration and purification (desalination, etc.) of colloid solutions.

System advantages

- Stable operation over the long term (pressurized backwashing process)

- Low running cost

- Contribute to automation and factory automation

- Clean operation environment

- Compact system

- Respond to diverse needs Major applications

Major application

- Purification of inorganic materials

- Desalination and concentration of organic emulsions

Automotive painting

Microza UF systems are widely used also in closed electrodeposition lines for automobiles,

home electric appliances, building materials, etc.

System advantages

- The backwashing system that realizes excellent filtration stability

- Simple to operate

- Intensive safety measures

- Space-saving, energy-saving, high reliability

Major applications

- Recovery of electrodeposition paint

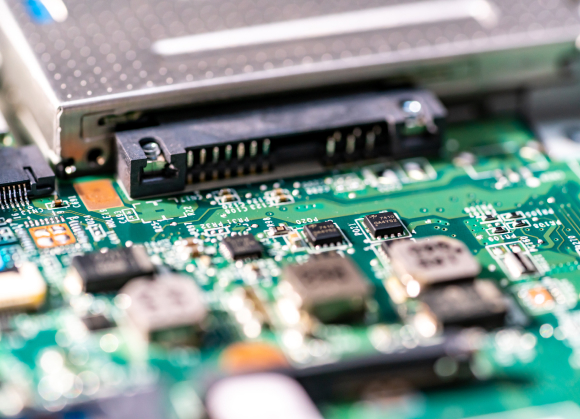

Electronics

Ultrapure water purified to extreme levels is indispensable in the manufacture

of electronic devices such as semiconductors and liquid crystal panels.

Microza is employed by electronics manufacturers around the world as a standard for the production of ultrapure water and wastewater recovery.

Major applications

- Ultrapure water

- Wastewater from silicon wafer polishing

- Wastewater from glass polishing

- Chemical mechanical planarization (CMP) wastewater

- Reverse osmosis (RO) pretreatment

- Organic wastewater

Water treatment

- Water purification and desalination of seawater

Water purification plants are rapidly increasing where membrane filtration is implemented to improve water quality, reduce maintenance labor and save space.

Microza has been introduced into many purification plants throughout the world and is receiving top-class ratings.

Major applications

- Water purification plant, small-scale water-supply system

- Clarification of underground water and river water

- Clarification of industrial water

- Reverse osmosis (RO) pretreatment for desalination of seawater

- Recycling of sewage and wastewater

Recovery of wastewater is important for environmental protection and the effective use of water resources.

Microza has been installed at large leisure parks and industrial plants to efficiently clarify sewage

and factory wastewater and eliminate microorganisms for recycling the water.

Major applications

- Sewage system

- Clarification of industrial wastewater for recycling

- Sewage purification

Recycling of industrial wastewater and sewage

Solution to shortages of potable water resources and industrial water