- Pharmaceuticals

- Separation technology

Renovation in Biopharmaceuticals Production and Productivity Improvement for Objectives (Antibodies, Proteins, Vaccines, Enzymes, etc.) based on Our Advanced Technologies

Microza responds to various challenges in pharmaceuticals

Increase yield of antibodies in separation process from

perfusion cultures of animal cells

Increase yield of proteins

in separation process from cultures solutions of E. Coli, yeast, ect.

Increase the yields

in the concentration and purification processes of vaccines and virus

Want to increase the yields

in the concentration and desalination processes of enzymes for industrial uses

Why Microza?

High productivity and filtration stability

The original membrane technology of Microza enables precise control of pore structures on the membrane, realizing high yields of target materials and stable filtration in the upstream and downstream membrane filtration separation processes of biopharmaceutical production.

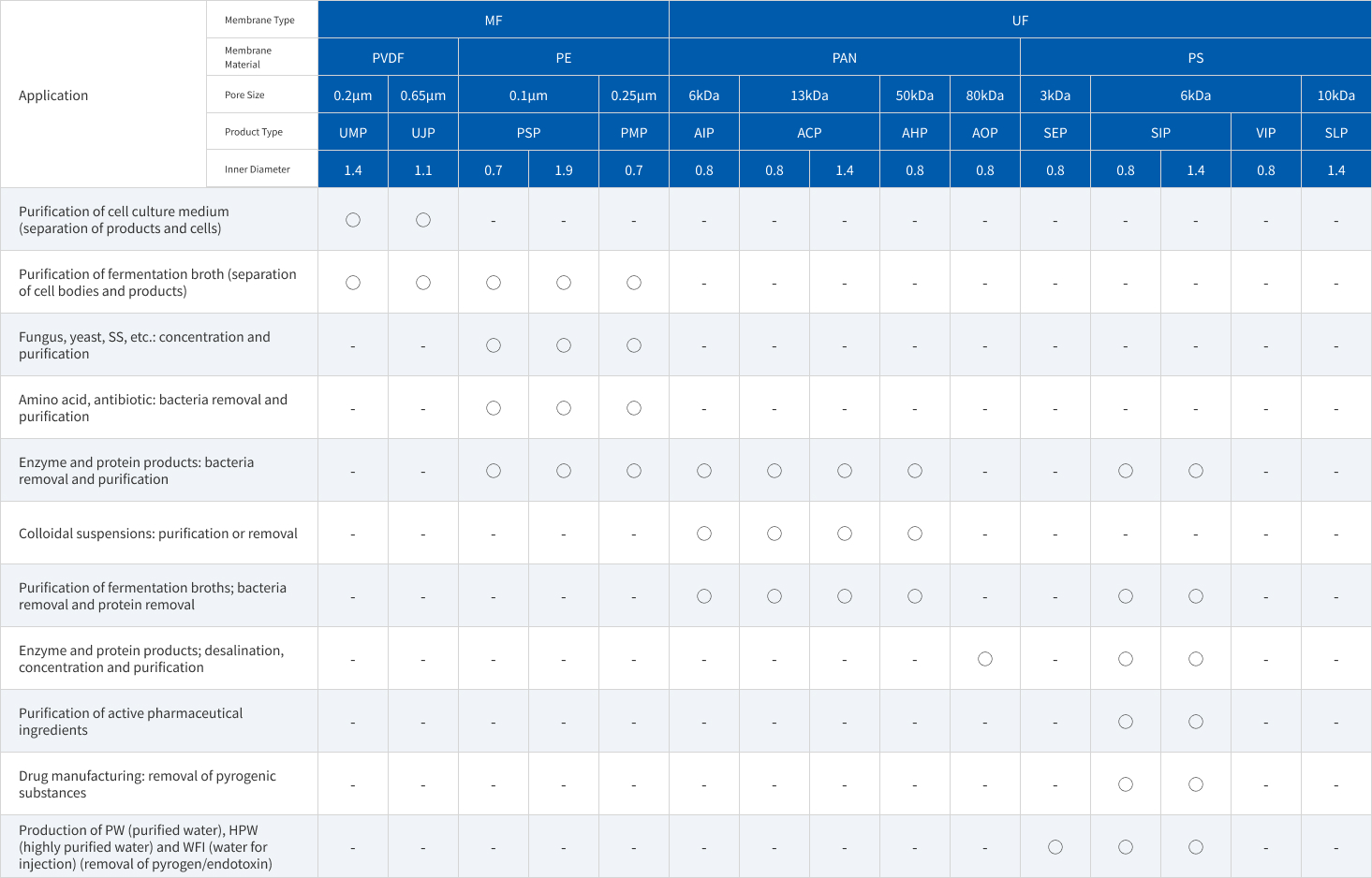

Extensive product lineup

A total of four membrane materials are available: PVDF and PE for MF, and PAN and PS for UF.

High antibody permeability

Polyvinylidene difluoride (PVDF) membrane demonstrates high antibody permeability in perfusion culture production by the combination of material properties (high durability and high sanitation as it allows steam sterilization) and fine pore structures (uniformity and communication property) on the membrane.

Low protein adsorption at separation from culture medium

Polyethylene (PE) membrane can separate proteins from culture medium without adsorbing them by its material properties (high durability and hydrophilicity) and the fine pore structures (uniformity and void ratio) on the membrane.

High productivity of the protein concentration process with PAN membrane

Polyacrylonitrile (PAN) membrane demonstrates excellent separation performance of enzymes in the concentration and purification processes by the combination of material properties (high hydrophilicity and low adsorption) and the fine pore structure (uniformity) on the membrane.

Our Products

MF membrane; UMP/UJP Series

MF membranes specialized for biopharmaceutical applications. Achieves long-term perfusion cell culture under high cell density.

UF membrane; AP and SP series

UF membranes with excellent sanitary properties and widely used in food, pharmaceutical, and biotechnology applications.

MF membrane; P Series

MF membranes made of polyethylene material and applicable to a wide range of pH.

Applications

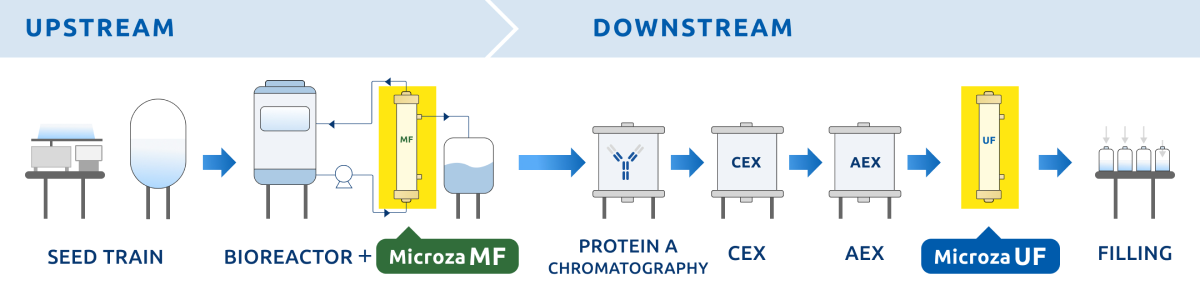

- Upstream: UMP and UJP series provide especially high antibody recovery rates and filtration stability in continuous culture production of monoclonal antibodies.

- Downstream: PNA series provides high protein recovery rates in batch culture production of vaccines and protein pharmaceuticals.

Examples of Microza application in upstream and downstream processes