Stable quality even in high-temperature environments

AZP™ optical resin from Asahi Kasei with excellent heat resistance. Even under high temperatures, it maintains product shape, retains transparency, and resists yellowing. It also exhibits minimal change in spectral transmittance, allowing high color fidelity to be maintained.

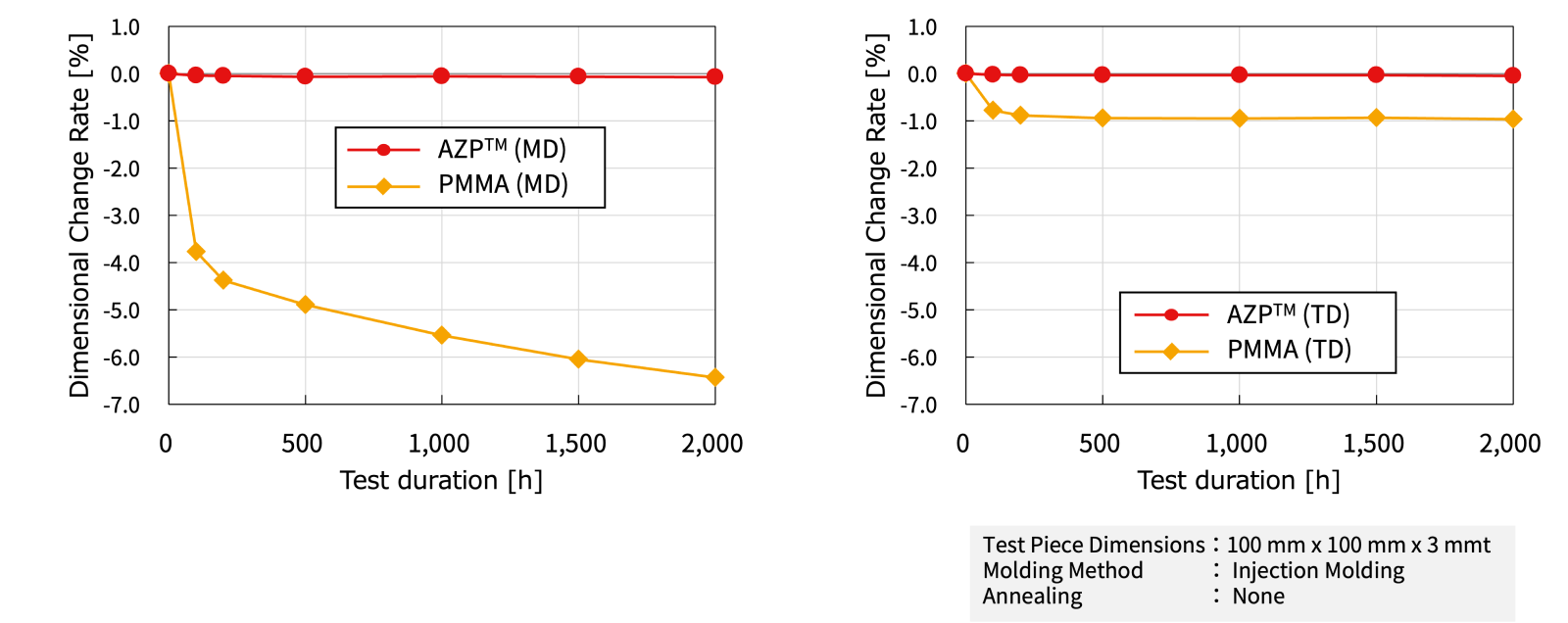

Maintaining product shape

AZP™ shows smaller dimensional change than polymethyl methacrylate (PMMA) in a high-temperature test at 110°C for 2,000 hours.

This indicates that AZP™ can provide long-lasting shape stability in components exposed to high-temperature environments.

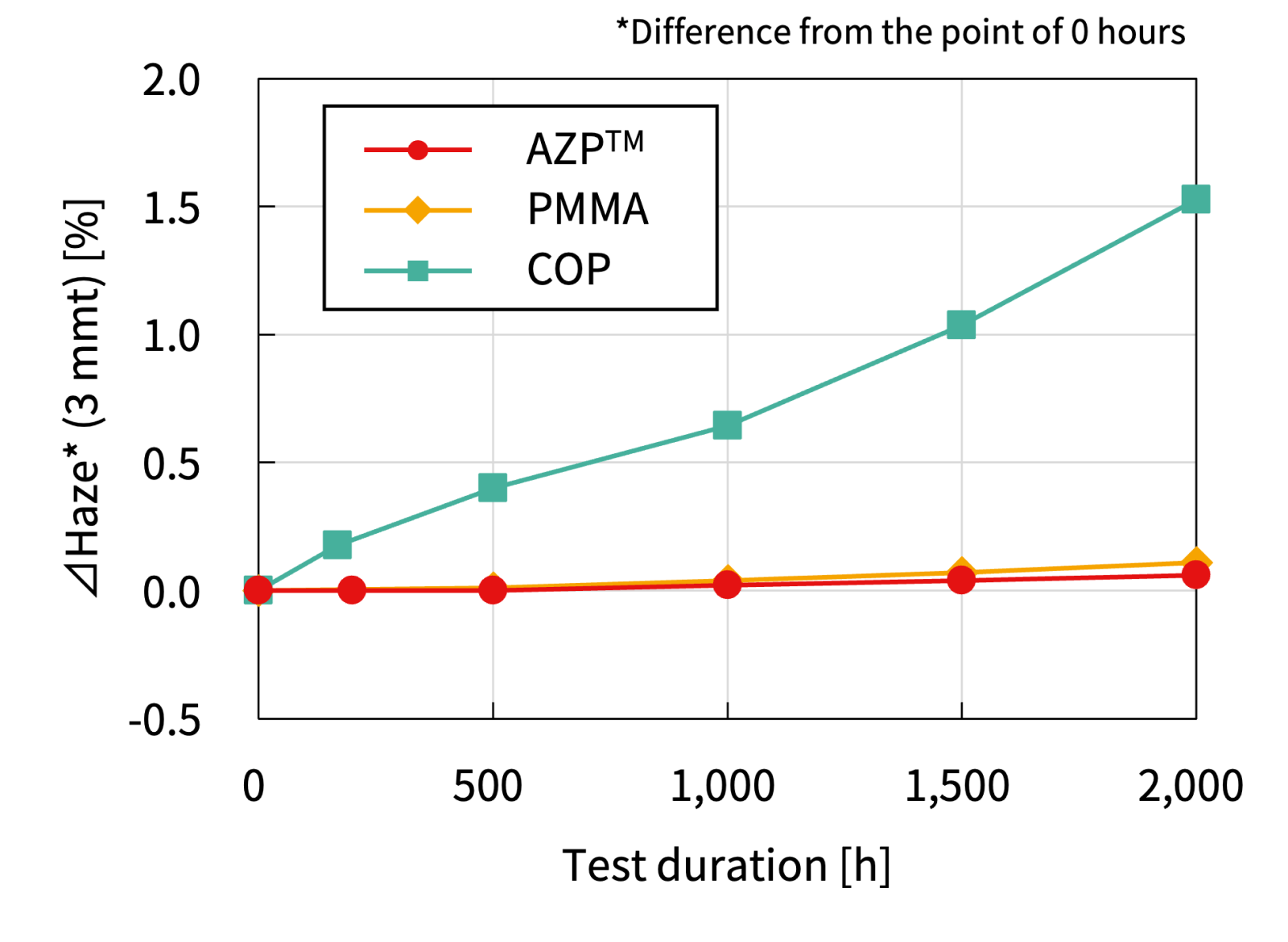

Retaining transparency

AZP™ shows smaller change in haze than cyclic olefin polymer (COP) in a 2,000-hour high-temperature test at 110°C. The results for AZP™ were comparable to polymethyl methacrylate (PMMA), which is generally considered to have high heat resistance.

This indicates that AZP™ can provide long-lasting transparency in headlamps and other components that have prolonged exposure to high temperatures.

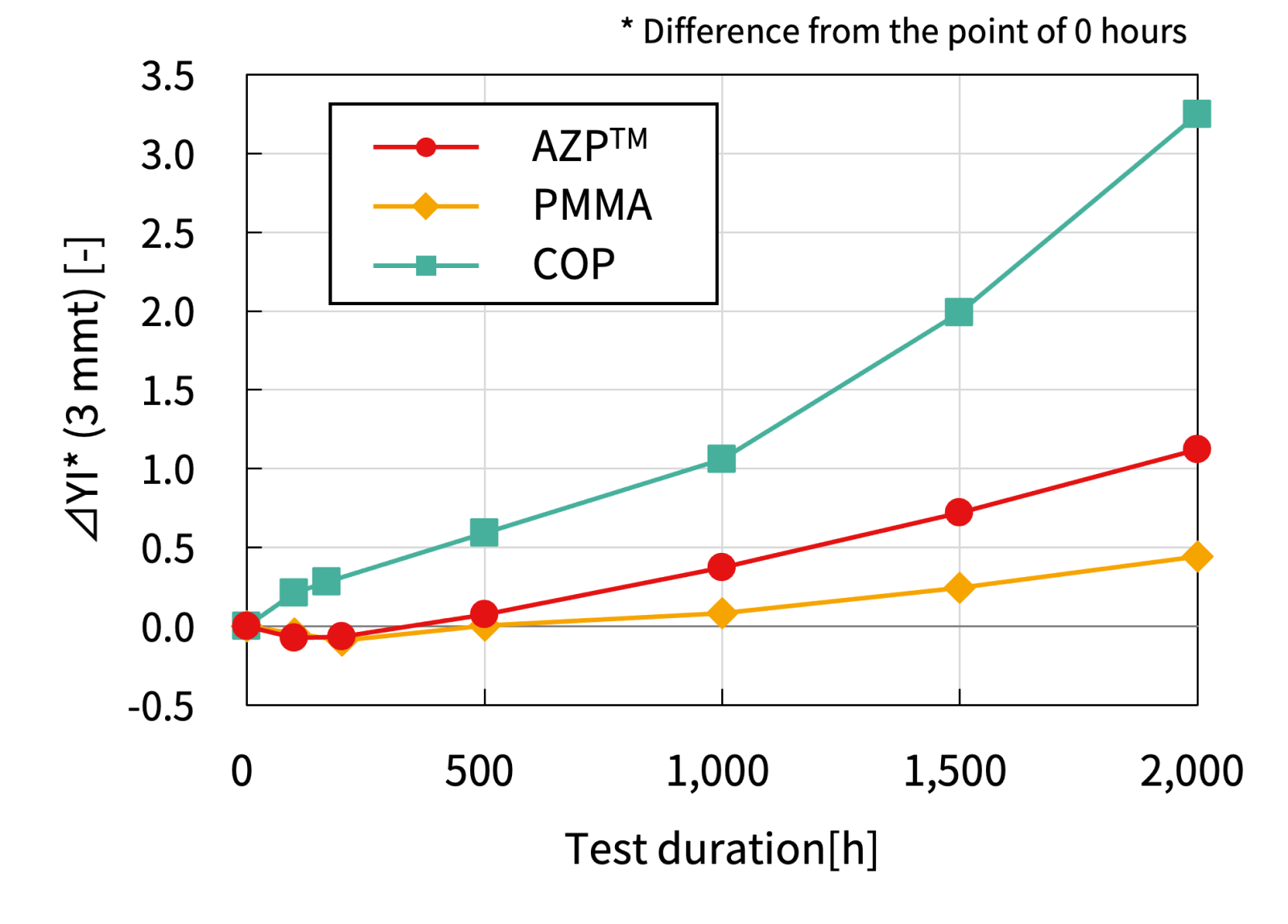

Minimal yellowing

AZP™ shows smaller change in yellowness index (YI) than cyclic olefin polymer (COP) in a 2,000-hour high-temperature test at 110°C. The results for AZP™ were comparable to polymethyl methacrylate (PMMA), which is generally considered to have high heat resistance.

This indicates that AZP™ can maintain good product appearance without yellowing when exposed to high temperatures.

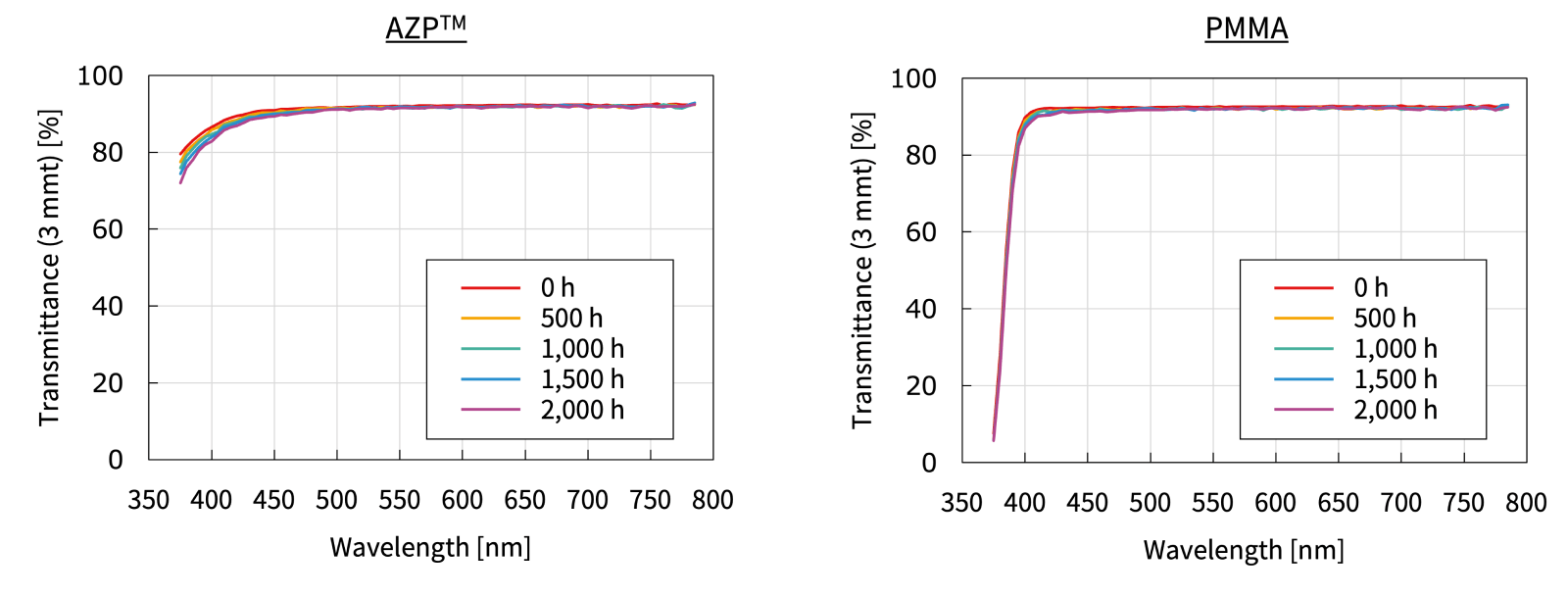

Maintaining reproducibility of all colors

AZP™ ️shows slight change in spectral transmittance in a 2,000-hour high-temperature test at 110°C. The results were similar to polymethyl methacrylate (PMMA), which is generally considered to have high heat resistance.

This means that AZP™ can provide long-term color fidelity in applications such as automotive instrument panels that are subject to prolonged exposure to high temperatures.